Crushing pretreatment system for hazardous wastes

A dangerous waste and pretreatment technology, which is applied in the fields of environmental protection, garbage crushing and hazardous waste treatment, can solve the problems of secondary pollution, reduction of incineration efficiency, coking of spray guns, etc., and achieve the effect of high degree of automation, thorough incineration and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

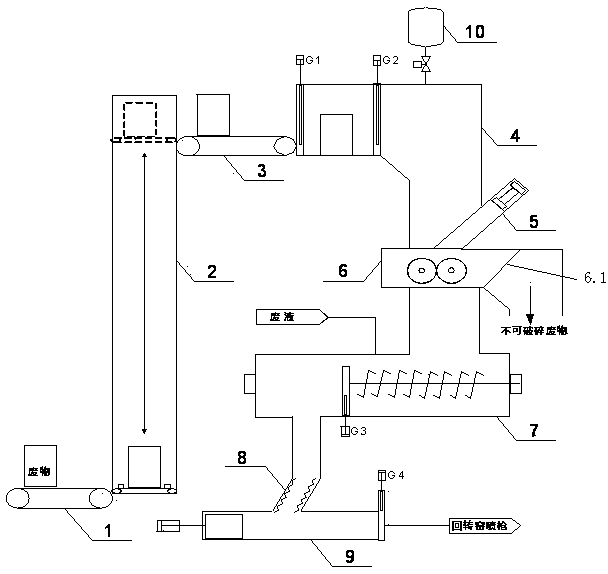

[0021] see figure 1 , the present invention includes a roller conveyor 1 connected in sequence, a vertical automatic elevator 2, a roller conveyor 2 3, a chute 4, a feeder 5, a shearing crusher 6, a mixer 7, a screw Conveyor 8 and plunger pump 9. A safety explosion-proof tank 10 is arranged above the chute 4 .

[0022] The first hydraulic sealing door G1 and the second hydraulic sealing door G2 are successively arranged at the entrance of the chute 4, and a conveying chain is arranged at the lower part between the first hydraulic sealing door G1 and the second hydraulic sealing door G2. The shearing crusher 6 is provided with an automatic reversing system, and the side of the shearing crusher 6 is provided with a discharge door 6.1 controlled by hydraulic opening and closing. A weir plate G3 is set in the mixer 7; a sliding gate valve G4 is disposed at the outlet of the plunger pump 9. Two oxygen measuring points are respectively set on the chute 4 and the mixer 7 to mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com