Waste salt resourceful treatment process and special equipment thereof

A treatment process and recycling technology, applied in the field of industrial waste salt separation and recycling process and special equipment, can solve the problems of difficult separation of organic matter, complex treatment process, high implementation cost, and reduce the cost of hazardous waste disposal. Control and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

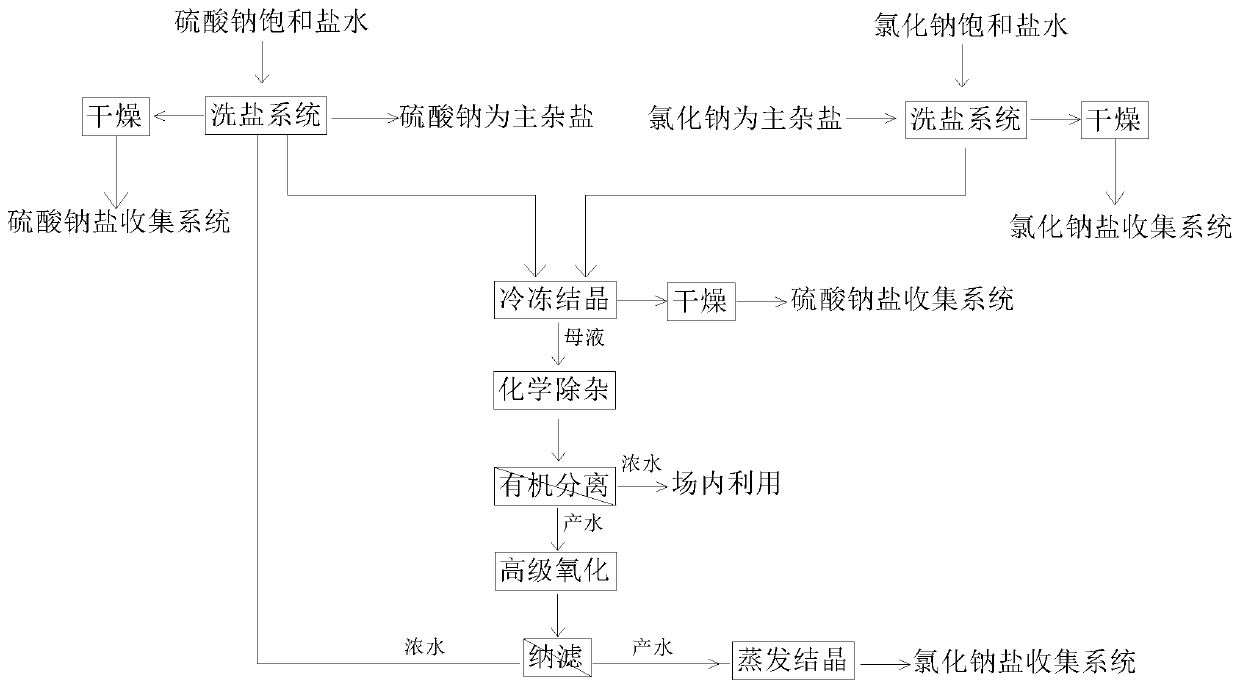

Method used

Image

Examples

Embodiment

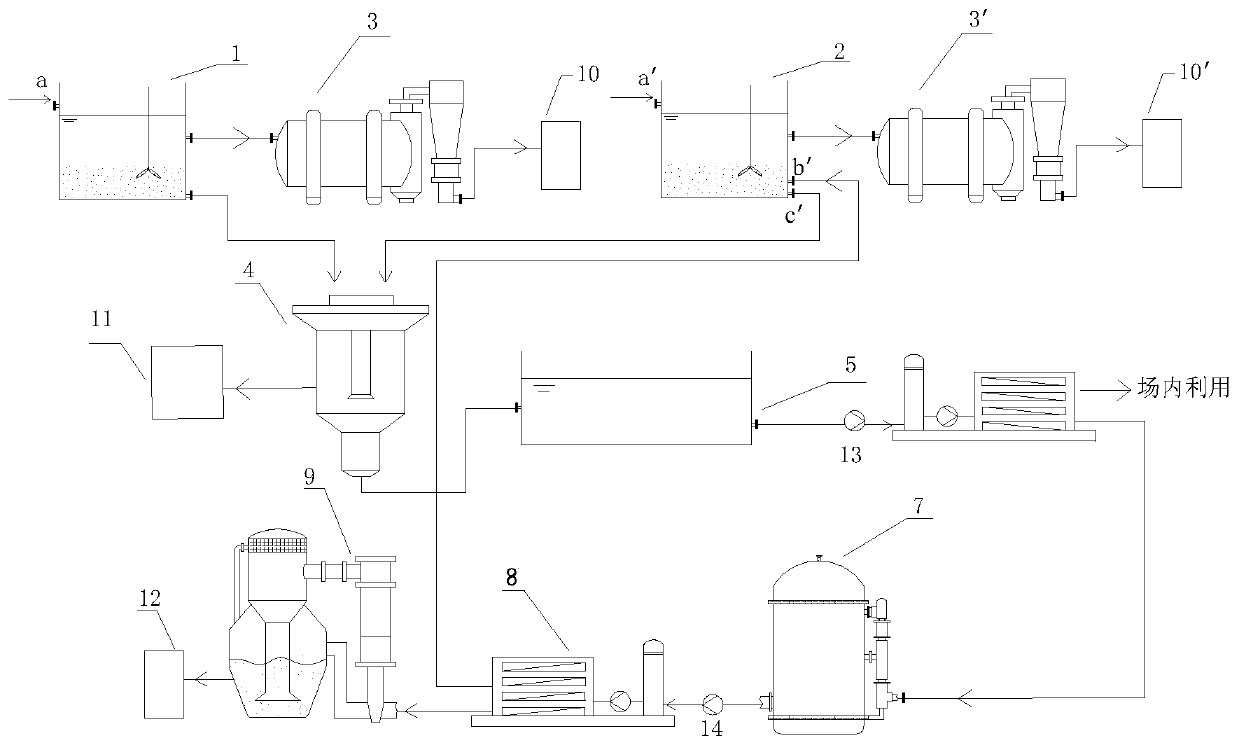

[0033] as attached figure 2 As shown, a special equipment for waste salt resource treatment process, which includes salt washing system A1, salt washing system B2, dryer A3, dryer B3', freeze crystallization system 4, impurity removal system 5, organic separation system 6 , oxidation reactor 7, nanofiltration system 8, evaporation crystallization system 9, sodium chloride salt collection system A10, sodium chloride salt collection system B11, sodium sulfate salt collection system A12, sodium sulfate salt collection system B10′, the first inlet Water pump 13, second water inlet pump 14;

[0034] The liquid output end of the salt washing system A1 and the discharge port c' of the salt washing system B2 are connected with the feed port of the frozen crystallization system 4, and the solid output end of the salt washing system A1 is connected with the sodium chloride salt collection system A10, and the salt washing The solid output end of the system B2 is connected with the sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com