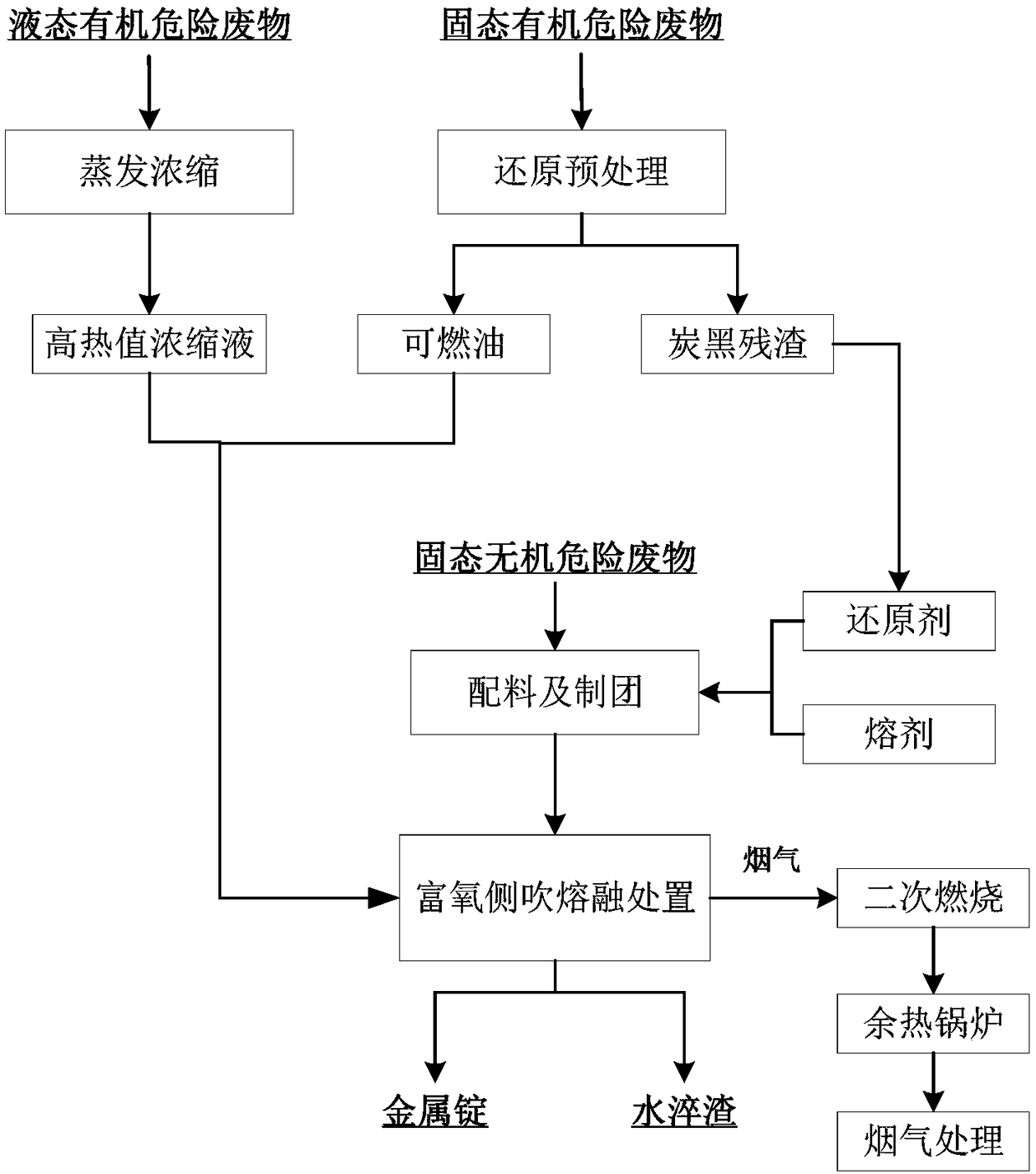

Hazardous waste melting disposal method

A hazardous waste and disposal method technology, applied in waste treatment, solid waste removal, chemical instruments and methods, etc., can solve the problems of high fuel consumption, waste of resources, inability to recycle resources, etc., and achieve the suppression of the production of dioxins , Reduce the amount of waste gas generated, and the effect of thorough resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Solid organic hazardous waste: fine distillation residue (HW11), dye and paint waste (HW12), organic resin waste (HW13), with an average organic content of 70% (m / m) and an average water content of 30%.

[0047] Liquid organic hazardous waste: waste mineral oil (HW08), oil / water, hydrocarbon / water mixture (HW09).

[0048] Solid inorganic hazardous waste: surface treatment waste (HW17), incineration disposal residue (HW18), non-ferrous metal smelting waste (HW48), other waste (HW49), spent catalyst (HW50). The metal content is very low, with an average copper content of 2% (dry basis), an average nickel content of 1.5% (dry basis), and an average zinc content of 1.0% (dry basis).

[0049] (1) Low temperature pretreatment

[0050] Treat 50 tons of the above-mentioned solid organic hazardous waste per day, control the reduction pretreatment temperature to 450°C, and obtain carbon black residue and combustible fuel oil after reduction pretreatment for 60 minutes, and obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com