Waste lead-acid battery lead plaster molten bath smelting treatment method

A waste lead-acid battery, molten pool smelting technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry and other directions, can solve problems such as hidden dangers, achieve high efficiency, solve environmental pollution, and save investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

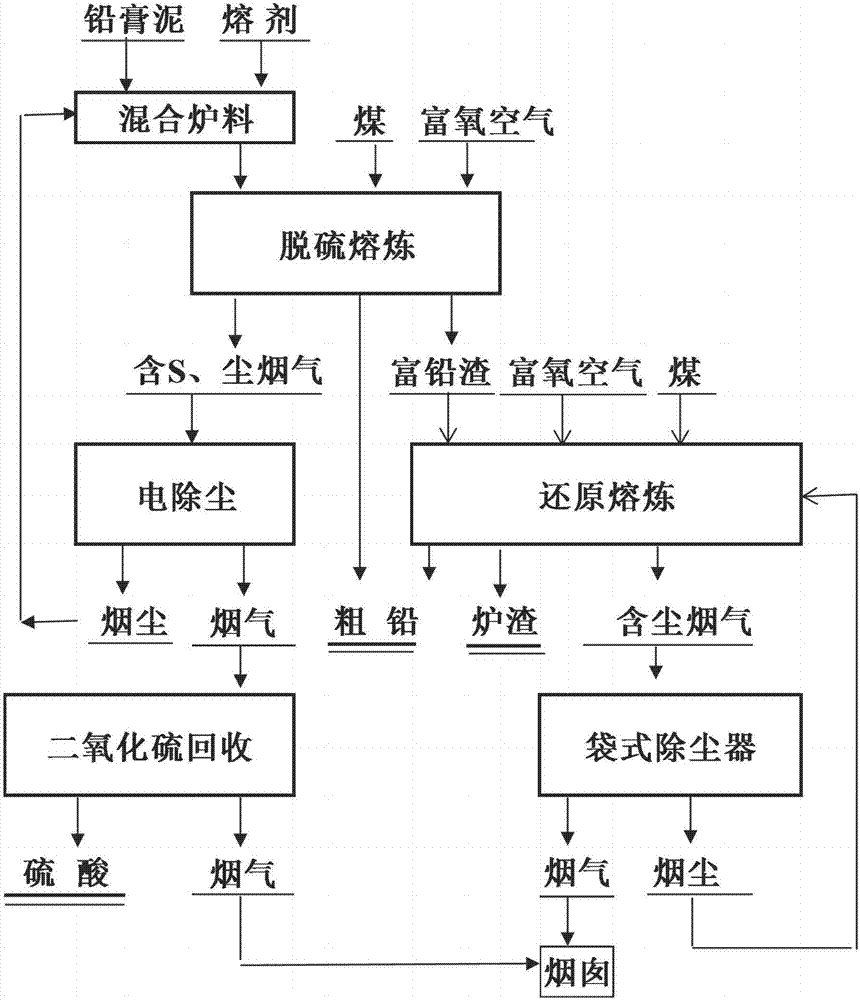

[0022] like figure 1 As shown, the oxygen side-blowing furnace is used to process waste lead-acid batteries, which is completed in two stages. One furnace (less than 150,000 tons / year for waste lead-acid batteries) can be used for periodic production operations, or two furnaces, one for oxidation and the other for continuous production operations (for processing more than 150,000 tons / year of lead-acid batteries) .

[0023] The first stage: desulfurization and smelting. Firstly, the waste battery lead plaster mud and limestone (flux) that have been decomposed and separated, and dehydrated by pressure filtration are automatically batched, and then transported by a belt conveyor and continuously fed from the top of the furnace. In the furnace, granular coal (coke) is added to the furnace at the same time, and oxygen-enriched air is sent into the furnace through the tuyere at the lower part of the furnace.

[0024] PbSO 4 =PbO+SO 3 (1)

[0025] SO 3 = SO 2 +1 / 2O 2 (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com