Incinerating and proportioning method for hazardous waste

A technology of hazardous waste and types, applied in combustion methods, incinerators, combustion types, etc., can solve problems such as insufficient consideration, and achieve the effect of ensuring stability and improving incineration efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

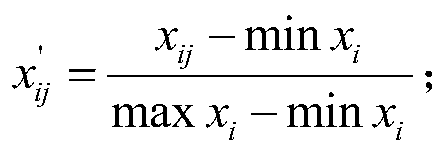

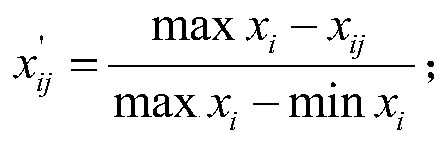

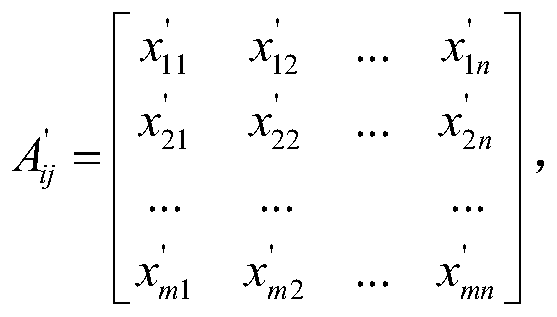

[0025] In order to ensure the stability of incineration and improve the efficiency and quality of incineration, the present invention considers the hazardous waste compatibility method of empowering hazardous waste treatment by gray correlation method, including the following steps:

[0026] A. Problem description.

[0027] Suppose a hazardous waste treatment enterprise has m types of hazardous waste that can be incinerated in the warehouse, M={M 1 ,M 2 ,...,M m}, considering the calorific value, moisture content, corrosion degree and toxicity of each hazardous waste, now it is necessary to incinerate the hazardous waste in the warehouse, and it is necessary to determine the proportion of hazardous waste incinerated to ensure the temperature of the incinerator during the incineration process in a relatively stable state.

[0028] B. Problem hypothesis.

[0029] To solve the problem in step A, certain assumptions need to be met, and the detailed assumptions are described as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com