Vertical type hazardous waste treatment device

A waste treatment, vertical technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of toxic and harmful substances, large floor space, complicated installation, etc., and achieve convenient operation, sufficient combustion, and easy discharge of residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

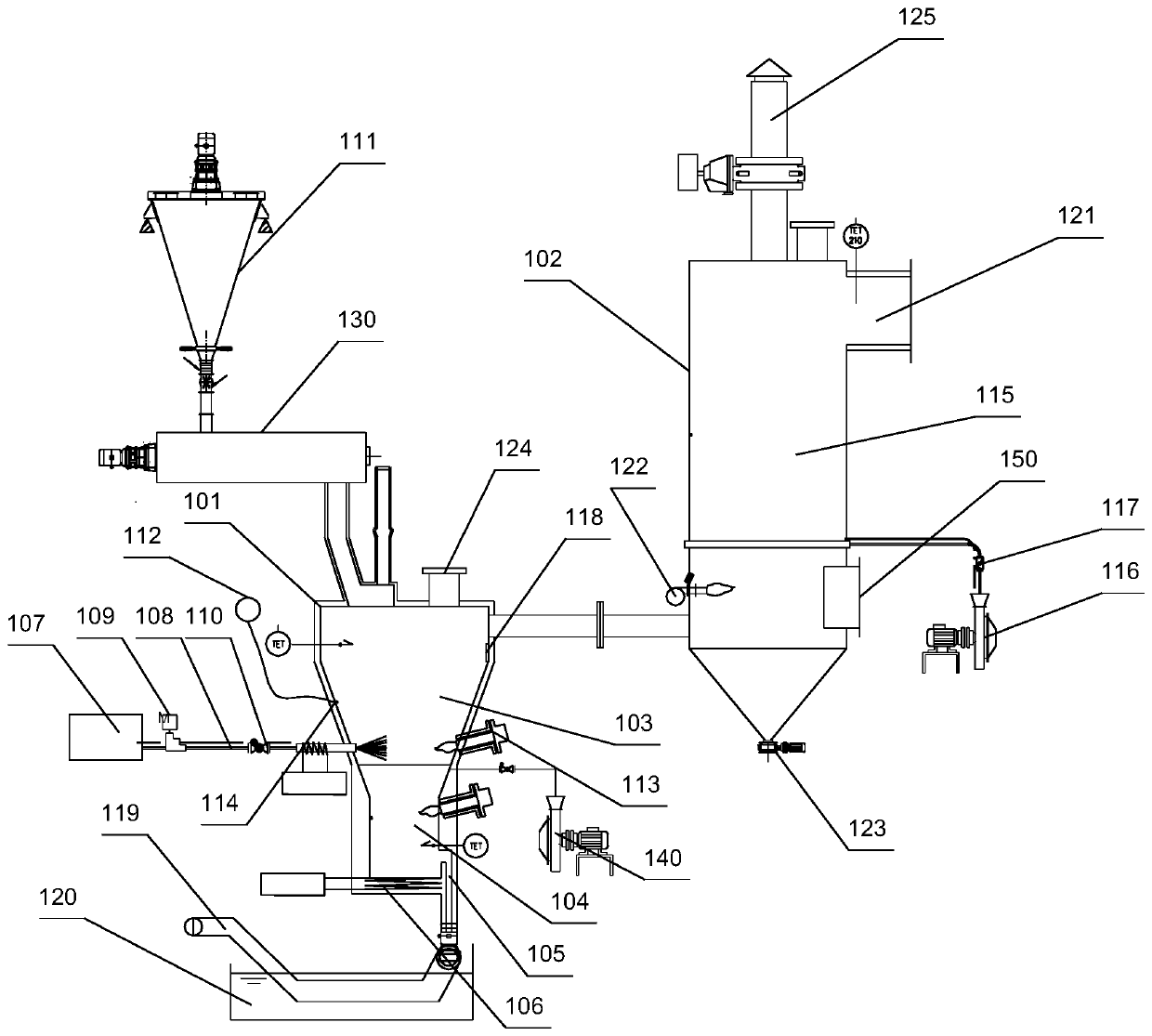

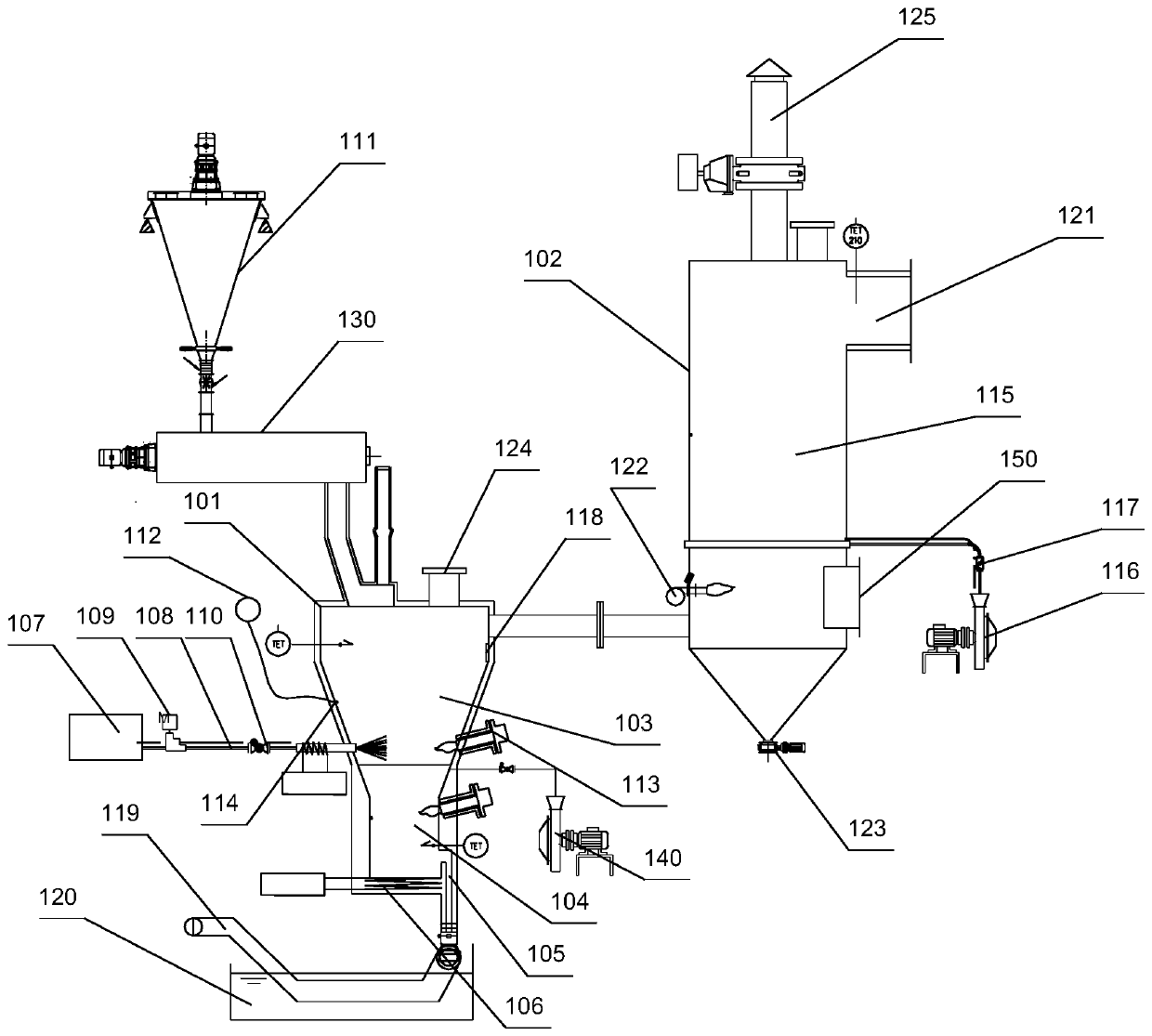

[0024] Such as figure 1 As shown, a vertical hazardous waste treatment device includes a first furnace body 101 and a second furnace body 102 connected to each other; the top of the first furnace body 101 is provided with a solid waste inlet, and the first furnace body 101 below the solid waste inlet A combustion chamber 103 and a slag chamber 104 connected to each other are provided in sequence in the interior; a heating device 106 is provided at the outer bottom of the slag chamber 104; It is communicated through pipelines; the present invention mainly includes the first furnace body 101 and the second furnace body 102, which can be used in more spaces by replacing different pipelines according to the terrain, and has the advantages of simple structure, convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com