Barreled viscous colloidal hazardous waste treatment and recovery system device

A technology of waste treatment and recycling system, which is applied to the removal of solid waste, cleaning methods using liquids, cleaning methods and utensils, etc. It can solve problems such as social conflicts, dirty and smelly treatment places, and lack of treatment technology to achieve work High efficiency, high degree of automation, and the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

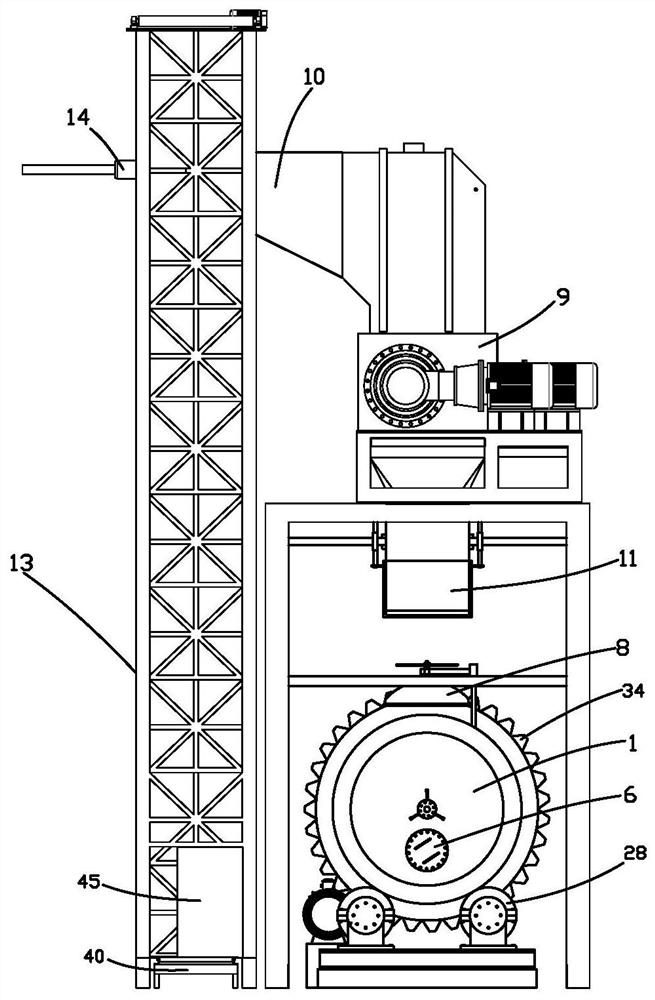

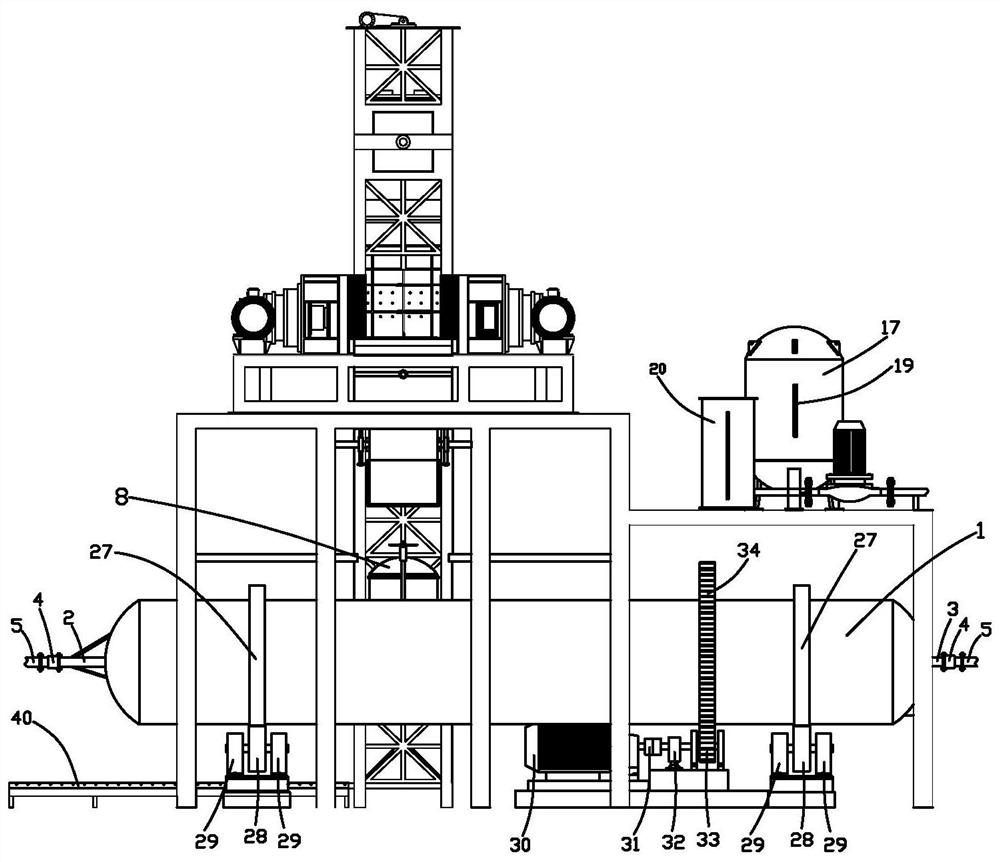

[0031] with the following Figure 1 to Figure 9 As shown, specific embodiments of the present invention will be described.

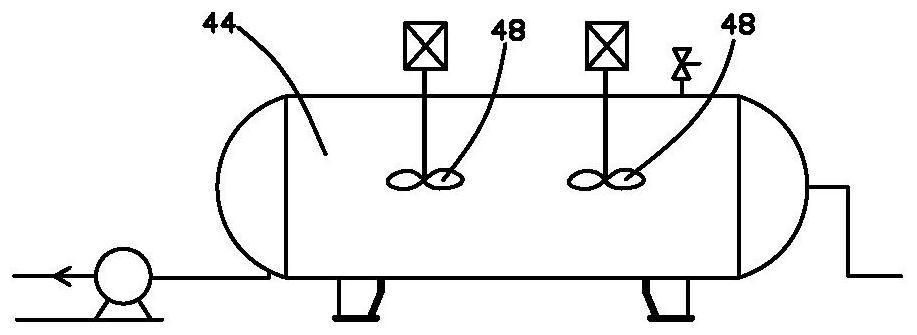

[0032] The barreled viscous jelly hazardous waste treatment and recovery system device of the present invention, such as figure 1 , image 3 or Figure 5As shown in the figure, the bucket 45 is torn into pieces, the viscous colloidal hazardous waste is separated from the fragments of the bucket, the viscous colloidal hazardous waste is homogeneously processed into fluid liquid chemical raw materials, and the viscous colloidal hazardous waste in barrels is processed and recycled. The system device includes a horizontally placed cleaning drum 1, a drum support device, and a drum drive device that can drive the cleaning drum 1 to rotate around its central axis on the drum support device. It is connected with the back-end central pipe 3, and is connected to the external pipeline 5 through the rotary joint 4; the external pipeline 5 is respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com