Manufacturing device and manufacturing method of optical fiber preform rod

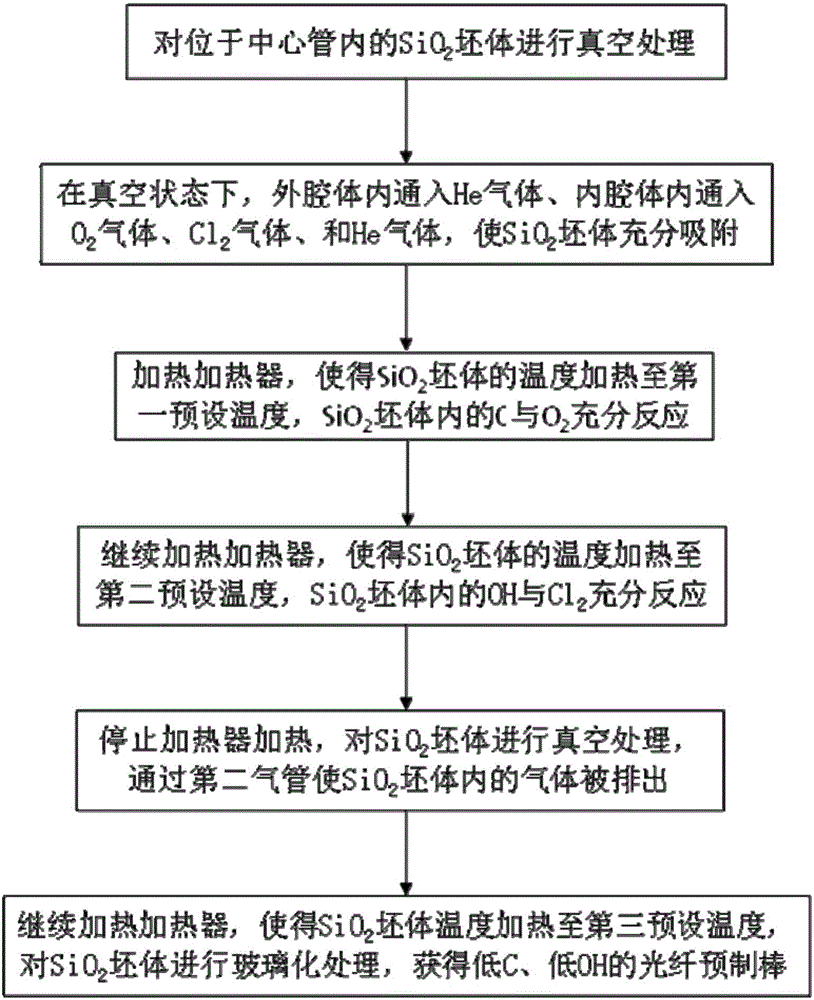

A technology of optical fiber preform and manufacturing method, which is applied in the field of optical communication, achieves the effect of simple structure and solving the problems of carbon removal and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

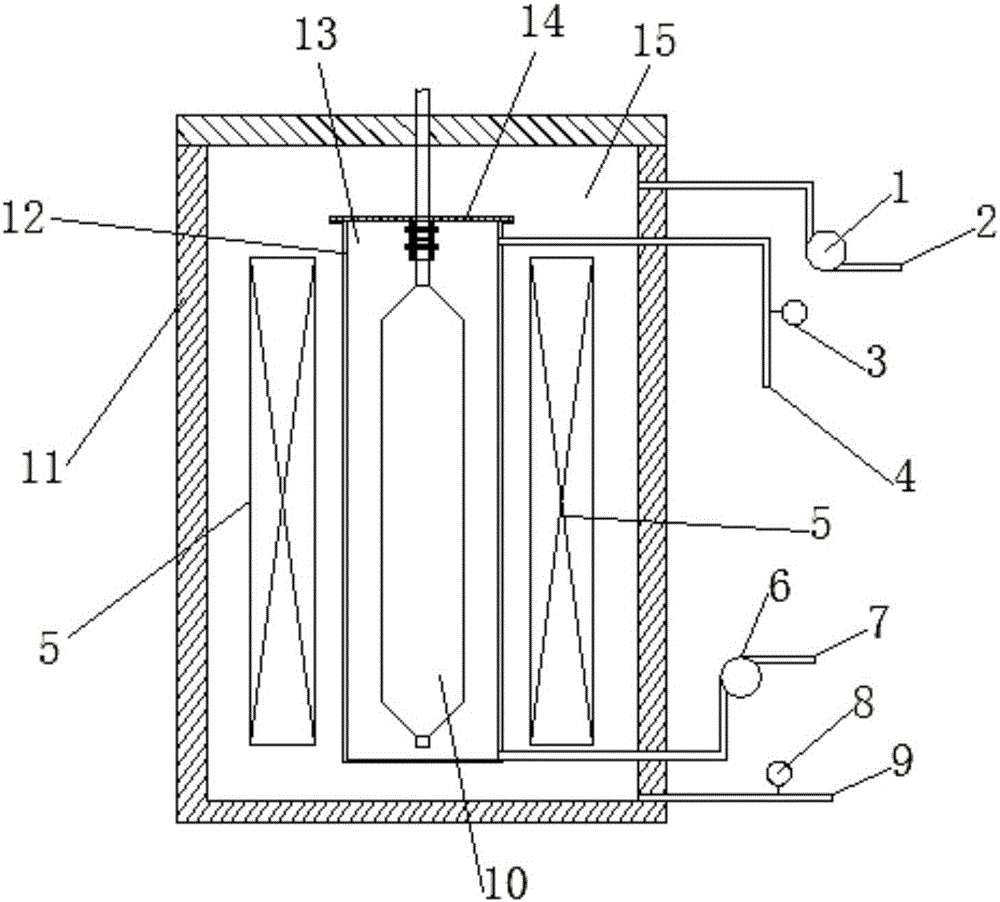

[0040] First embodiment: with CH 4 and O 2 as the reactive gas, and with SiCl 4 As a raw material, a density of 0.4 to 0.8 g / cm is obtained by deposition 3 SiO 2 Body 10.

no. 2 example

[0041] The second embodiment: with H 2 and O 2 As a reaction gas, and using OMCTS as a raw material, the density is 0.4~0.8g / cm2 obtained by deposition method 3 SiO 2 Body 10.

no. 3 example

[0042] The third embodiment: with CH4 and O2 as reaction gases, and OMCTS as raw material, the density is obtained by deposition method of 0.4 ~ 0.8g / cm 3 SiO2 body 10.

[0043] The SiO2 green body 10 prepared by the above three deposition methods is placed in the oxidation dehydration sintering furnace 11 of the present invention, and covered with a sealing cover 14. The manufacturing method of the optical fiber preform of the present invention also has three embodiments.

[0044] The first embodiment of the manufacturing method of the optical fiber preform of the present invention: SiO is made by the manufacturing method of the first embodiment of the SiO blank body 10 2 The blank 10, the specific contents of the first, third and sixth steps of the manufacturing method of the optical fiber preform of the present invention are as follows:

[0045] The specific steps of the above first step are:

[0046] Step A1: The SiO2 green body 10 is placed in the sintering furnace 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com