Anaerobic digestion device and process for pre-treating sludge with high solid content by heating method

A technology of anaerobic digestion and high solid content, applied in biological sludge treatment, sludge treatment through temperature control, etc., can solve the problems of large transport volume, high cost of sludge anaerobic digestion, difficult sludge hydrolysis and acidification, etc. , to achieve the effects of increasing anaerobic digestion rate and methane production, easy temperature control, and increased hydrolysis and acidification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

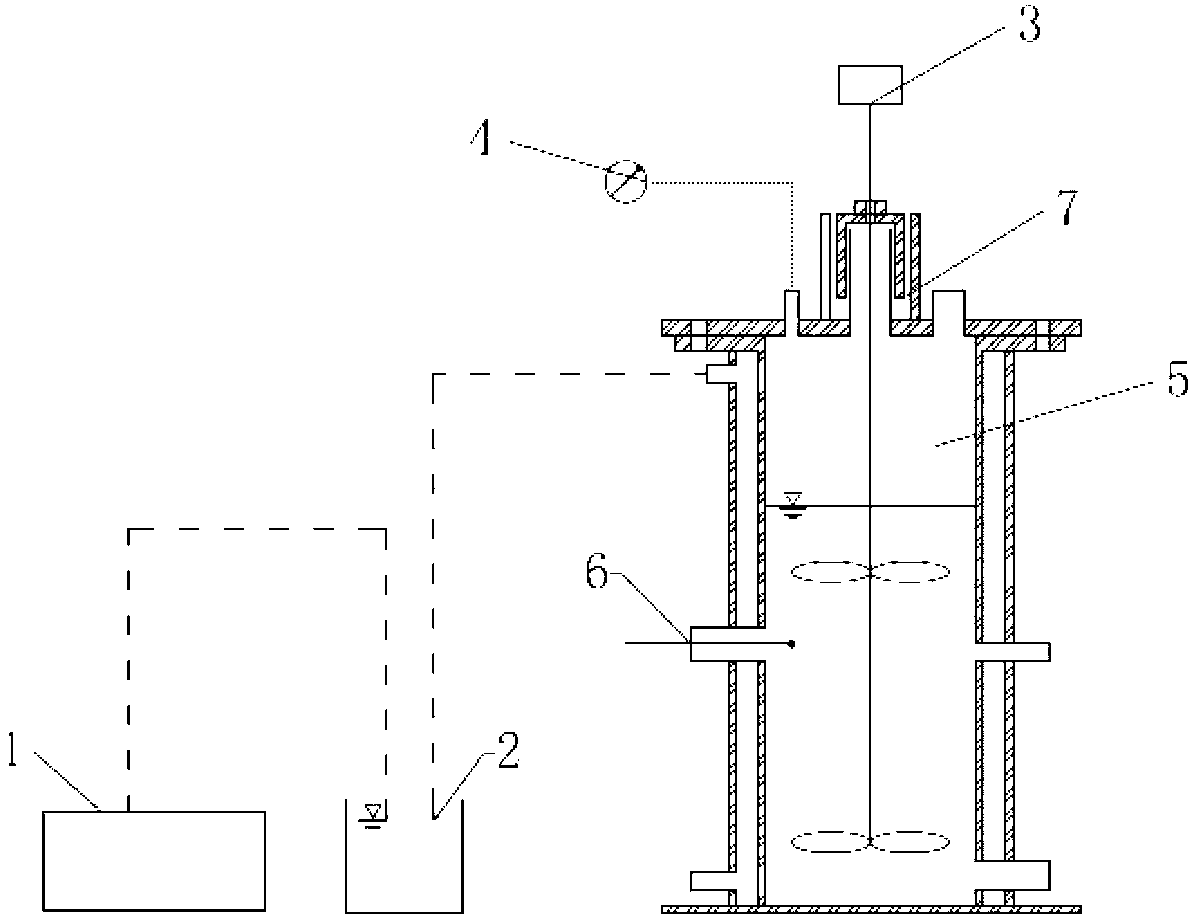

[0030] This embodiment includes the following steps:

[0031] Step 1. In the sludge mixing unit 1, the solid distribution conveyor belt transports the sludge cake with a solid content of 15%, and the liquid transport pipe transports the sludge dewatering supernatant with the same weight. After stirring, the solid content is formed 10% sludge, and the sludge dewatering supernatant is the liquid after the sludge is filtered and dehydrated;

[0032] Step 2: After adjusting the solid content of the sludge, it is driven into the heating tube in the heating tank 2 through a peristaltic pump, and heated for pretreatment at 70°C for 30 minutes;

[0033] Step 3. Add the pretreated sludge into the anaerobic digestion tank 5 for agitated anaerobic digestion. In order to ensure the complete mixing and full contact between the materials in the anaerobic digestion tank 5 and the sludge, agitator 3 The speed is 90r / min, stirring for 20 minutes per hour, and the thermostatic water bath jacket is us...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1. In the sludge mixing unit 1, the solid distribution conveyor belt transports the sludge cake with a solid content of 25%, and the liquid transport pipe transports the sludge dewatering supernatant according to the same weight. After stirring, the solid content is formed 10% sludge, and the sludge dewatering supernatant is the liquid after the sludge is filtered and dehydrated;

[0038] Step 2: After adjusting the solid content of the sludge, it is driven into the heating tube in the heating tank 2 through a peristaltic pump, and heated for pretreatment at 70°C for 45 minutes;

[0039] Step 3. Add the pretreated sludge into the anaerobic digestion tank 5 for agitated anaerobic digestion. In order to ensure the complete mixing and full contact between the materials in the anaerobic digestion tank 5 and the sludge, agitator 3 The speed is 120r / min, stirring for 20 minutes per hour, and the thermostatic water bath jac...

Embodiment 3

[0042] This embodiment includes the following steps:

[0043] Step 1. In the sludge mixing unit 1, the solid distribution conveyor belt transports the sludge cake with a solid content of 25%, and the liquid transport pipe transports the sludge dewatering supernatant according to the same weight. After stirring, the solid content is formed 10% sludge, and the sludge dewatering supernatant is the liquid after the sludge is filtered and dehydrated;

[0044] Step 2. After adjusting the solid content of the sludge, it is driven into the heating tube in the heating tank 2 through a peristaltic pump, and heated for pretreatment at 70°C for 60 minutes;

[0045] Step 3. Add the pretreated sludge into the anaerobic digestion tank 5 for agitated anaerobic digestion. In order to ensure the complete mixing and full contact between the materials in the anaerobic digestion tank 5 and the sludge, agitator 3 Rotation speed is 150r / min, stirring for 30 minutes per hour, and thermostatic water bath ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com