A method for improving the ammonification rate of chemical industry wastewater containing organic nitrogen

A chemical wastewater and rate technology, applied to chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc., can solve the problems of difficult removal of ammonia nitrogen and low ammonification rate of chemical wastewater, and achieve simple methods, impact resistance, Manageable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

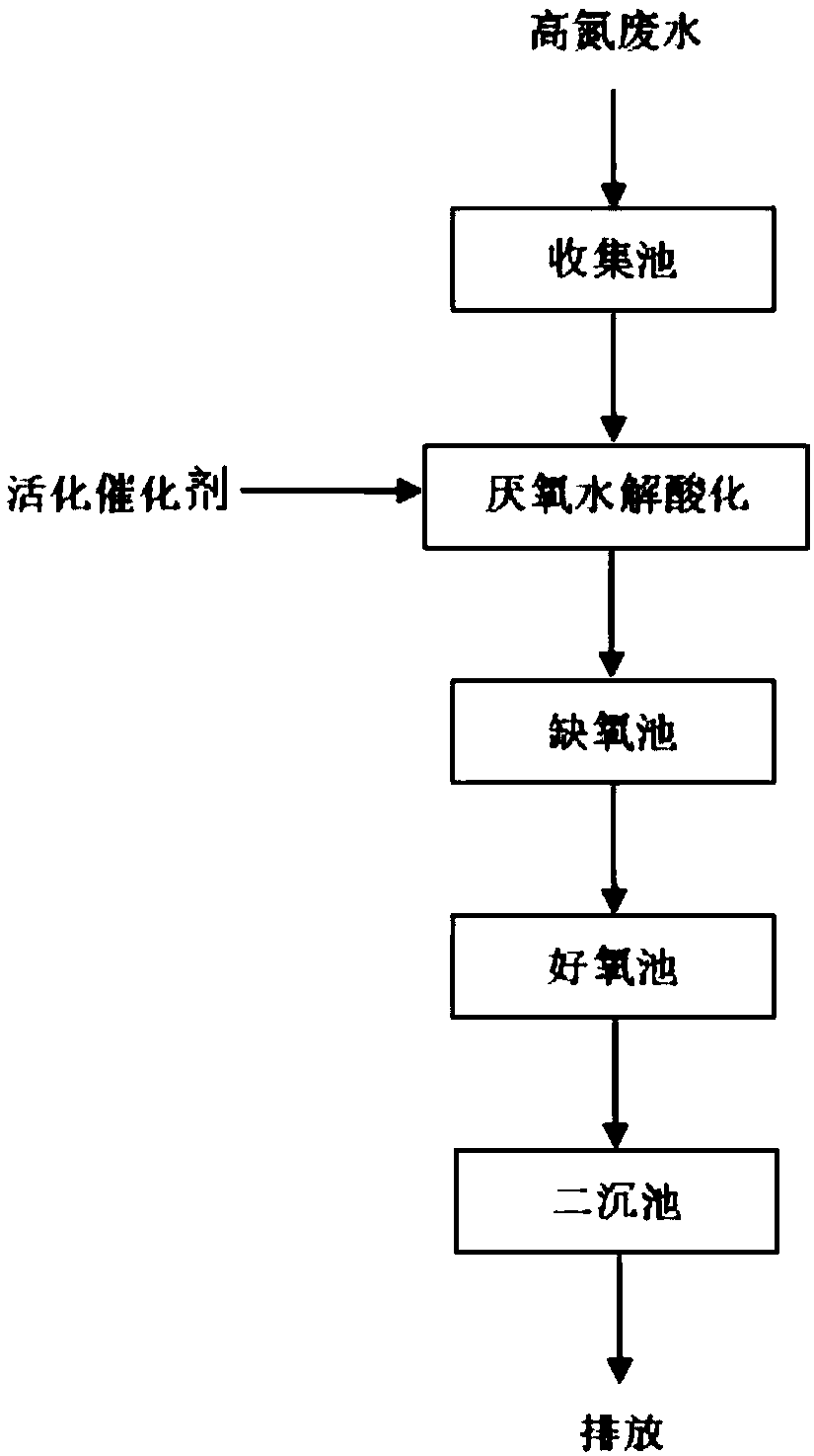

[0037] Such as figure 1 , a method for improving the ammonification rate of chemical industry wastewater containing organic nitrogen, the steps of which are:

[0038] A. Collect chemical wastewater through the wastewater collection tank; firstly collect chemical wastewater through the wastewater collection tank, and adjust the total nitrogen content of the wastewater in the collection tank to 100-150mg / L through laboratory tests, of which organic nitrogen content≤100mg / L, pH The control is 6-9, and the COD is 1500-2500mg / L.

[0039] B. The wastewater in the collection tank enters the anaerobic hydrolysis acidification tank; through the detection of the online sludge concentration meter, the sludge concentration in the anaerobic hydrolysis acidification tank is controlled to be 3500-4500mg / L, and the residence time of the wastewater is controlled according to the influent flow rate of 8-10h. On-line dissolved oxygen instrument detection, control dissolved oxygen DO≤0.2mg / L.

...

Embodiment 2

[0052] A printing and dyeing chemical enterprise in Yancheng Coastal Chemical Industry Park, Jiangsu Province, the sewage station before the transformation is as follows: collection pool→anaerobic hydrolysis acidification pool→anoxic / aerobic pool→secondary sedimentation tank→direct discharge, in order to improve the chemical industry containing organic nitrogen The ammonification rate of waste water proposes a method for improving the ammonification rate of industrial waste water containing organic nitrogen. Nitrogen content 75mg / L, pH=6, COD 1500mg / L;

[0053] In step B, the sludge concentration in the anaerobic hydrolysis acidification tank is 3500mg / L detected by the online sludge concentration meter, the influent flow rate is controlled so that the wastewater residence time is 8h, and the dissolved oxygen DO=0.2 is controlled by the online dissolved oxygen instrument detection mg / L;

[0054] In step C, the activated catalyst added in the anaerobic hydrolysis acidification...

Embodiment 3

[0059] For a pharmaceutical chemical company in Yancheng Coastal Chemical Industry Park, Jiangsu Province, the process before the renovation of the sewage station of the company is as follows: collection pool → anaerobic hydrolysis and acidification → anoxic / aerobic → secondary precipitation → direct discharge, in order to improve the ammonia content of chemical wastewater containing organic nitrogen A method for improving the ammonification rate of chemical industry wastewater containing organic nitrogen is proposed, the steps are the same as in Example 1, wherein, in step A, the water quality in the wastewater collection tank is as follows: total nitrogen 150mg / L, wherein organic nitrogen content 100mg / L, pH=9, COD is 2500mg / L;

[0060] In step B, the sludge concentration in the anaerobic hydrolysis acidification tank is controlled to be 4500mg / L through the detection of the online sludge concentration meter, the residence time of the wastewater is controlled according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com