A method for pre-fermentation and enhanced anaerobic digestion of excess sludge to produce methane

A technology of excess sludge and anaerobic digestion, applied in the field of environmental engineering, can solve the problems of slow acidification rate and low methane production efficiency, and achieve the effects of simple method, shortened digestion residence time and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

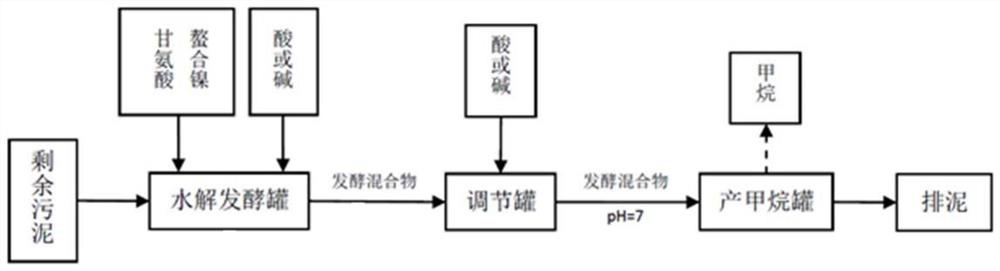

Method used

Image

Examples

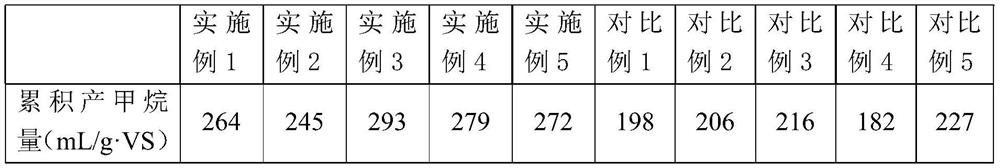

Embodiment 1

[0039] Concentrate the remaining sludge from the sewage plant to adjust the solid content to 20g / L, mix it with the digested sludge in the anaerobic digestion tank with a solid content of 50g / L at a volume ratio of 1:8, adjust the initial pH of the fermentation mixture to 5, and adjust the fermentation mixture per Kg 10mg of glycine chelated nickel was mixed, mixed evenly, and then fermented in a hydrolysis fermentation tank for 5 days. During the process, the pH was controlled at about 5, and the temperature was set at 33°C; after the pre-fermentation, the fermentation mixture was introduced into the adjustment tank, and the pH was adjusted to 7 and then introduced into the methanation tank, the final cumulative methane production was 264mL / g·VS.

Embodiment 2

[0041] Concentrate the remaining sludge from the sewage plant and adjust the solid content to 30g / L, mix it with the digested sludge in the anaerobic digestion tank with a solid content of 50g / L at a volume ratio of 1:8, adjust the initial pH of the fermentation mixture to 6, and adjust the fermentation mixture per Kg 20mg of glycine chelated nickel was mixed in proportion, mixed evenly and then fermented in a hydrolysis fermenter for 1 day. During the process, the pH was controlled at about 6, and the temperature was set at 35°C; 7 and then introduced into the methane tank, the final cumulative methane production was 245mL / g·VS.

Embodiment 3

[0043] Concentrate the remaining sludge from the sewage plant to adjust the solid content to 40g / L, mix it with the digested sludge in the anaerobic digestion tank with a solid content of 50g / L at a volume ratio of 1:8, adjust the initial pH of the fermentation mixture to 5.5, and adjust the fermentation mixture per Kg 30mg of glycine chelated nickel was mixed, mixed evenly, and then fermented in a hydrolysis fermentation tank for 3 days. During the process, the pH was controlled at about 5.5, and the temperature was set at 37°C; after the pre-fermentation, the fermentation mixture was introduced into the adjustment tank, and the pH was adjusted to 7 and then introduced into the methanation tank, the final cumulative methane production was 293mL / g·VS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com