Wide-width humidity self-adaptive fuel cell gas diffusion layer

A gas diffusion layer, fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low efficiency, difficult to implement on a large scale, and difficult to control the cost of alcohol solvents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A wide-width humidity-adaptive fuel cell gas diffusion layer, the specific formula and preparation parameters of the flattened layer and the corrugated layer are shown in Table 1.

[0063] Table 1 Formula and preparation parameters of leveling layer and corrugated layer in Example 1

[0064]

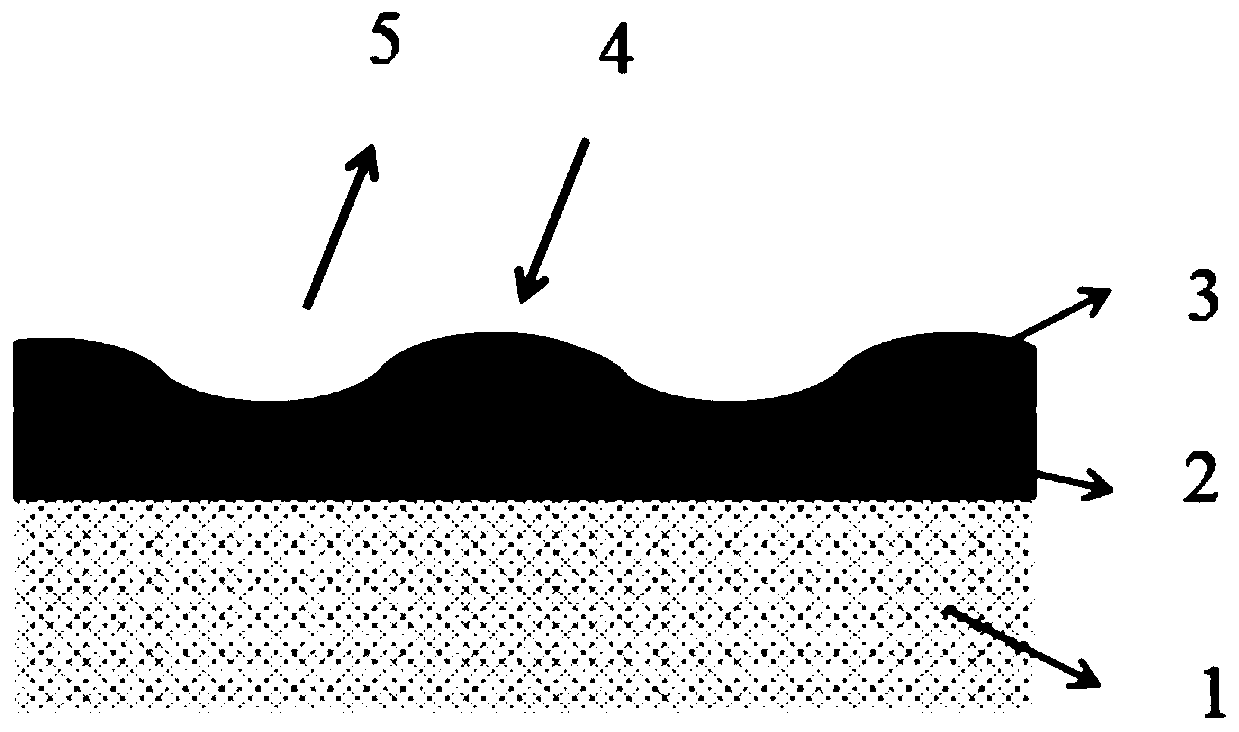

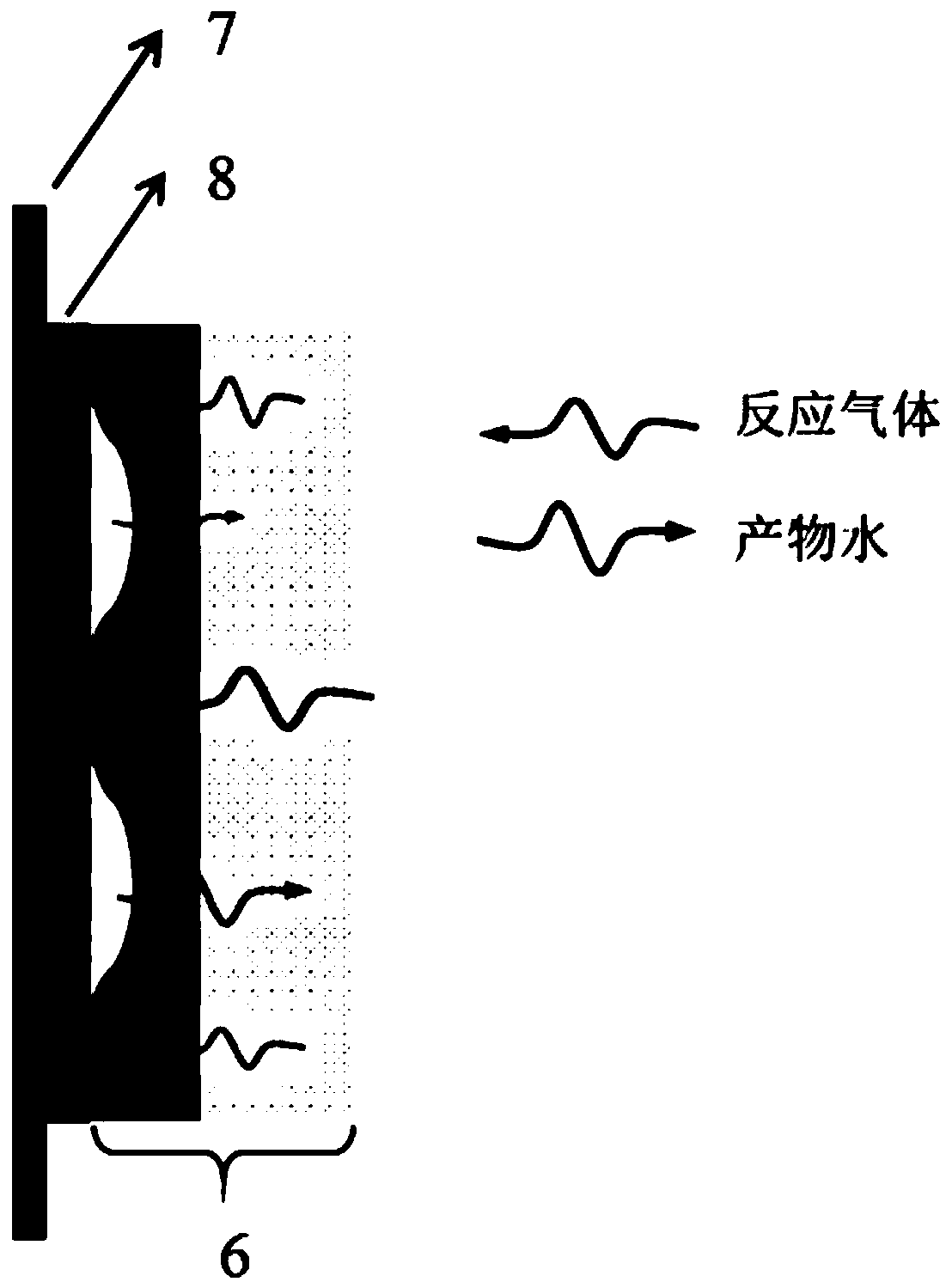

[0065] Obtain a wide-width humidity adaptive fuel cell gas diffusion layer, wherein the carbonaceous porous substrate has a self-weight of 35g / cm 2 , with a thickness of 200 μm and a peak pore size of 40 μm; a leveling layer with a thickness of 50 μm and a peak pore size of 100 nm; a corrugated layer with a thickness of 10 μm and a peak pore size of 70 nm. The peak-to-trough wave height is 3 μm, and the peak width is 150 μm. Carry out scanning electron microscopy under the scale of 1mm and 200μm, specifically as image 3 , 4 As shown, the results of the porosity test are shown in Figure 5-7 shown.

[0066] The prepared wide-width humidity-adaptive fuel cell gas diffusion ...

Embodiment 2

[0068] A wide-width humidity-adaptive fuel cell gas diffusion layer, the specific formula and preparation parameters of the flattened layer and the corrugated layer are shown in Table 2.

[0069] Table 2 The formulation and preparation parameters of the leveling layer and the corrugated layer in Example 2

[0070]

[0071] Among them, the carbonaceous porous substrate has a self-weight of 25g / cm 2 , with a thickness of 100 μm and a peak pore size of 30 μm; a leveling layer with a thickness of 10 μm and a peak pore size of 150 nm; a corrugated layer with a thickness of 10 μm and a peak pore size of 40 nm. The distance between the peak and the trough is 3 μm, and the peak width is 100 μm. The prepared wide-width humidity-adaptive fuel cell gas diffusion layer was assembled and tested with membrane electrodes, and the test conditions were the same as in Example 1. The polarization curve results under low humidification conditions are as follows Figure 8 As shown, both cath...

Embodiment 3

[0073] A wide-width humidity-adaptive fuel cell gas diffusion layer, the specific formula and preparation parameters of the flattened layer and the corrugated layer are shown in Table 3. Table 3 The formulation and preparation parameters of the leveling layer and the corrugated layer in Example 3

[0074]

[0075]

[0076] Among them, the carbonaceous porous substrate has a self-weight of 150g / cm 2 , with a thickness of 300 μm and a peak pore size of 50 μm; a leveling layer with a thickness of 100 μm and a peak pore size of 200 nm; a corrugated layer with a thickness of 20 μm and a peak pore size of 90 nm. The distance between the peak and the trough is 5 μm, and the peak width is 200 μm. The prepared wide-width humidity-adaptive fuel cell gas diffusion layer was assembled and tested with membrane electrodes, and the test conditions were the same as in Example 1. The polarization curve results under low humidification conditions are as follows Figure 8 As shown, both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com