Underground flow collection type ultrasonic wave Doppler flow-moisture content meter

A Doppler flow and ultrasonic technology, which is applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the flowmeter cannot realize fluid flow measurement, and achieve the effect of avoiding pooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

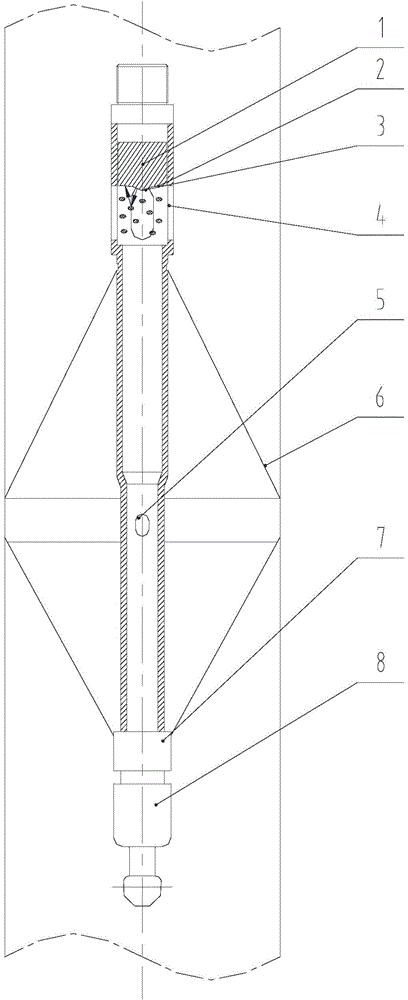

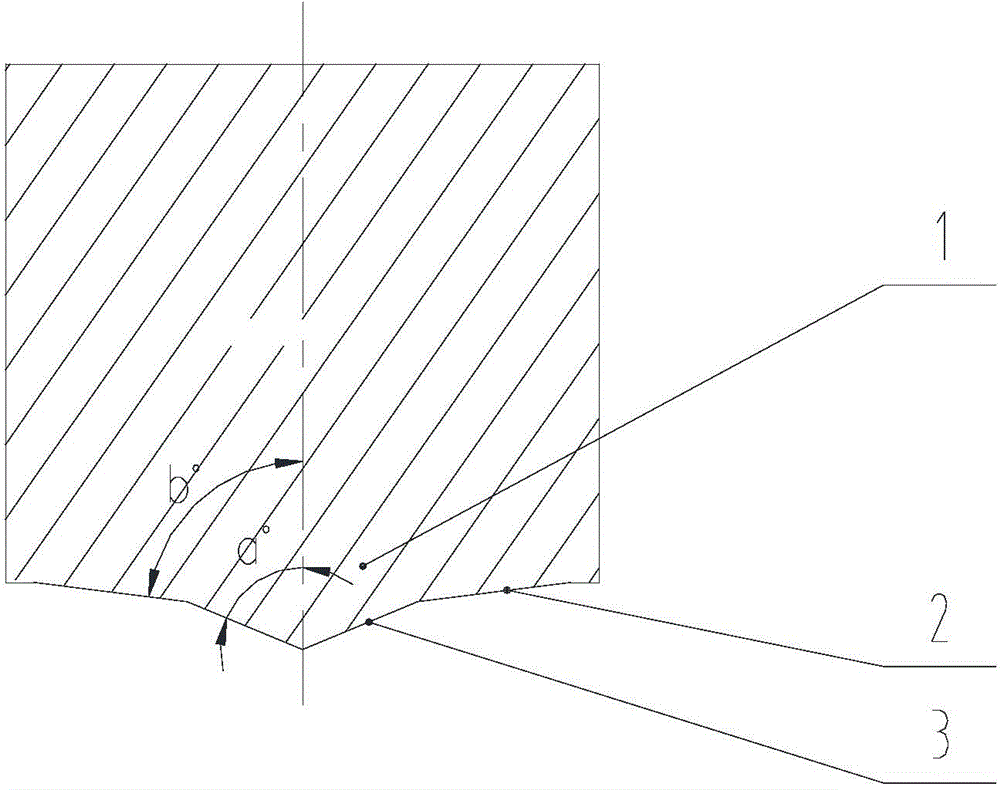

[0021] as attached figure 1 As shown, the downhole flow-collecting type ultrasonic multi-instrument Puller flow-water content meter includes a collector body 9 and a transmitting-receiving integrated ultrasonic probe 1, and the upper end of the collector body 9 is provided with a liquid outlet 4 , the lower end of the current collector main body 9 is connected to the sliding sleeve 7 and the driving device 8 in turn, the upper end of the current collector main body at the lower part of the liquid outlet 4 and the sliding sleeve 7 are connected with a current collecting umbrella 6, and the middle part of the current collector main body 9 is provided with a liquid inlet 5; the ultrasonic probe 1 is installed on the upper end of the liquid outlet 4; the end face of the ultrasonic probe 1 has a receiving surface 2 and a transmitting surface 3 respectively, and the receiving sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com