Oily sludge dehydration processing equipment and method thereof

A processing equipment and sludge dewatering technology, applied in the direction of dewatering/drying/concentrating sludge treatment, sludge oxidation treatment, etc., can solve the problems of difficult treatment and large differences, achieve low investment and operating costs, and reduce drilling costs. The effect of small area and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0063] 1. Equipment

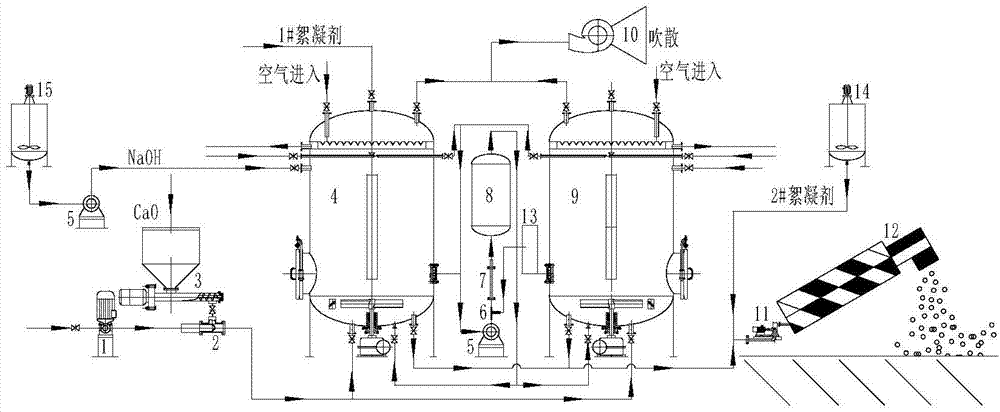

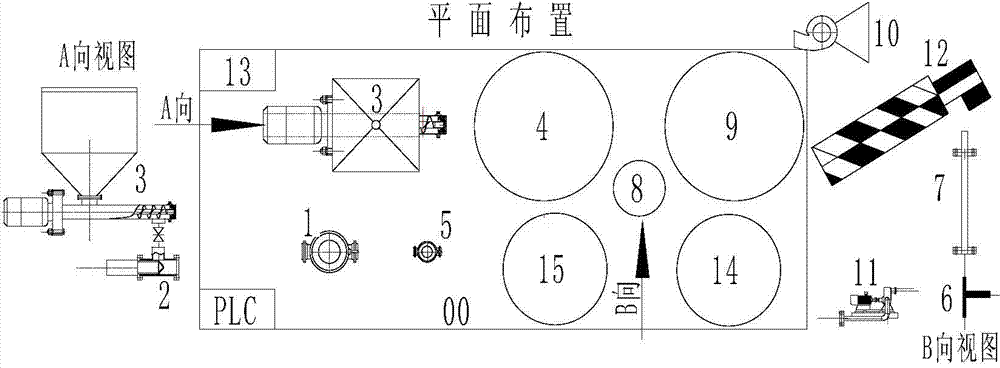

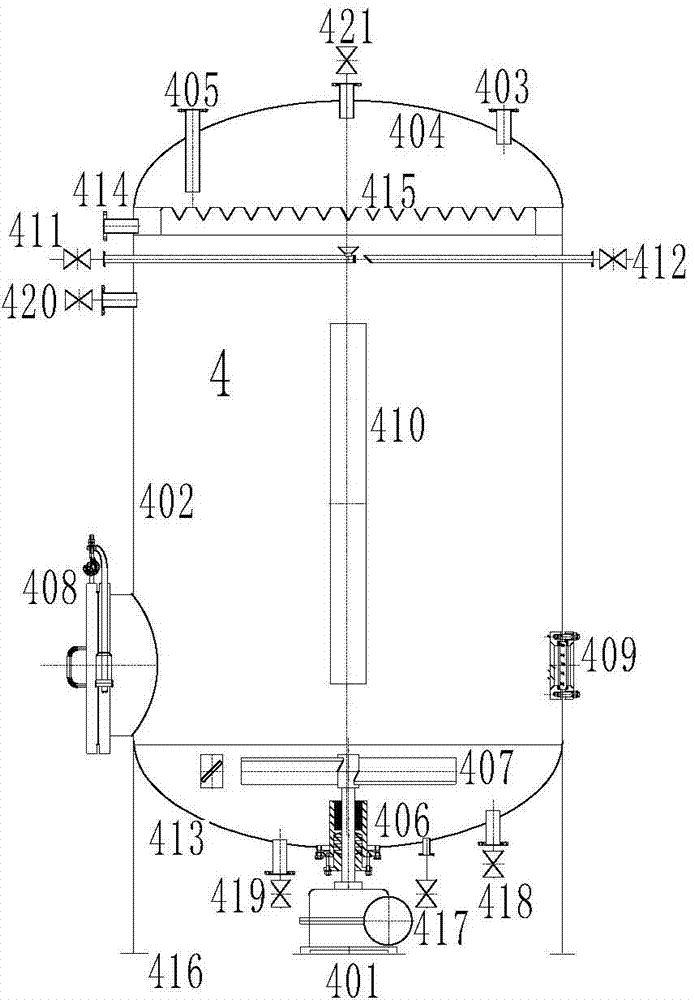

[0064] 1. Overall

[0065] Such as figure 1 , figure 2 , Figure 6 , this equipment includes skid base 00 (indicated by a rectangular box), delivery pump 1, Venturi device 2, screw feeder 3, first quenching and tempering reaction tank 4, circulation pump 5, ozone ejector 6, static mixer 7, ozone Strength control tank 8, second tempering reaction tank 9, blower 10, screw pump 11, screw pressure (stacked screw) dehydrator 12, ozone device 13, 2# flocculant regulating tank 14 and NaOH regulating tank 15;

[0066] The equipment is equipped with 15 kinds of functional parts, except that the screw pump 11 and the screw press (stack screw) dehydrator 12 are installed on another platform, and all 13 kinds of equipment are installed on the skid base 00;

[0067] Its connection relationship is:

[0068] The inlet end of the transfer pump 1 is connected to the oily slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com