Oil field extraction liquid electromagnetic agglomerating pretreatment device

A technology of pretreatment device and produced fluid, which is applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problem of rising water content of exported crude oil, difficulty in reaching the crude oil exporting index, and difficulty in subsequent separation process. To solve the problem of dehydration, improve the coalescence effect, and shorten the coalescence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

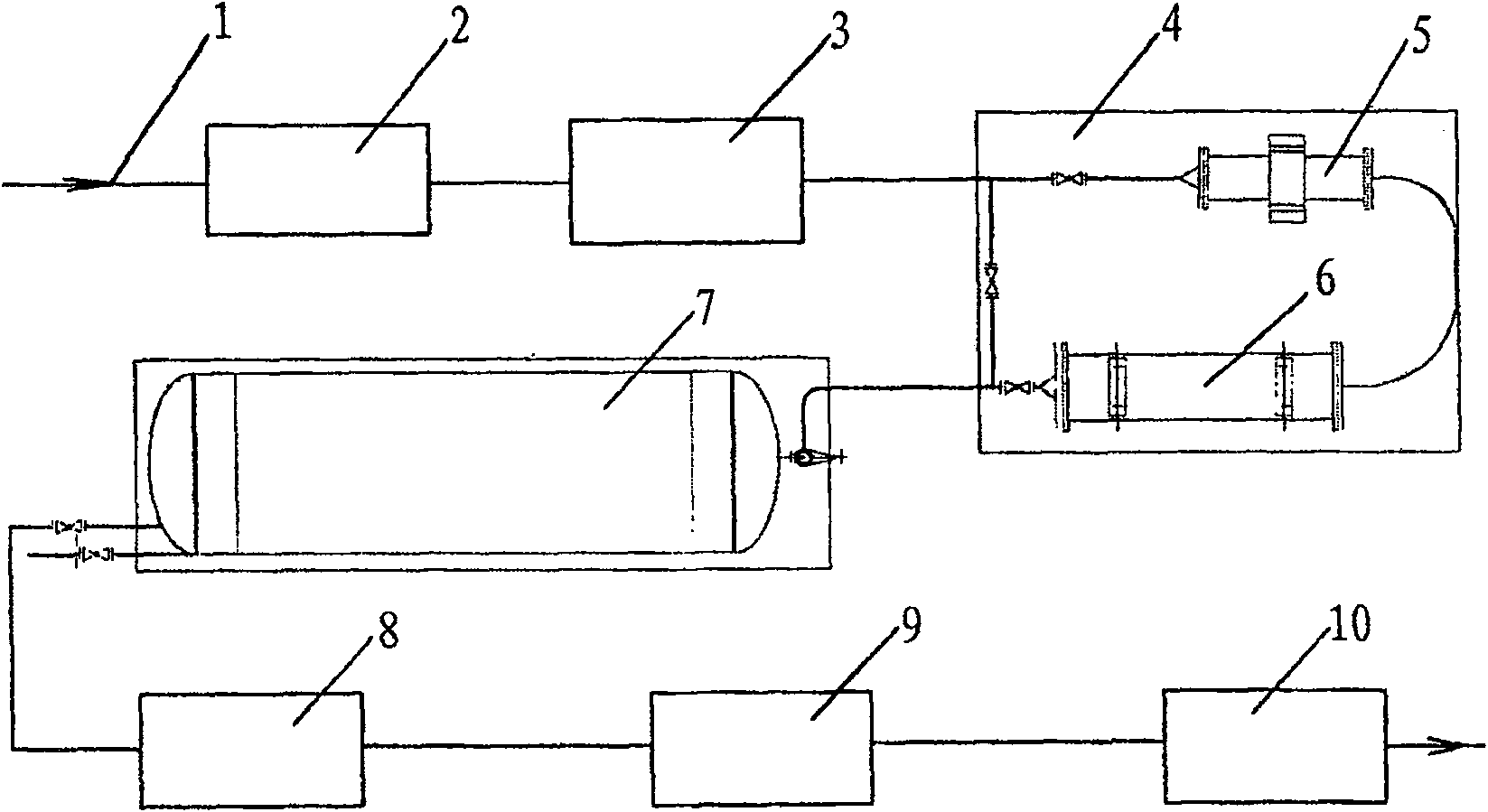

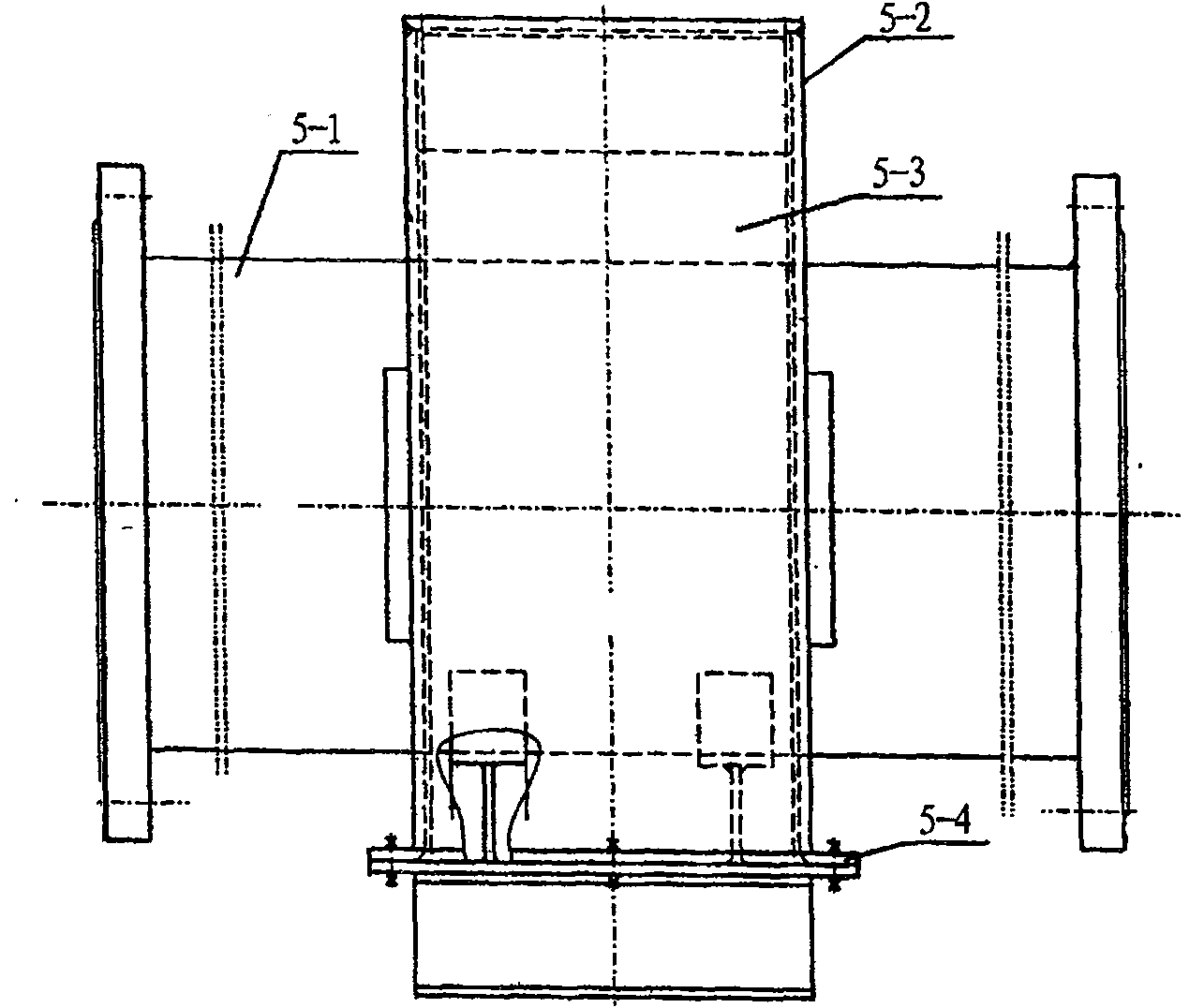

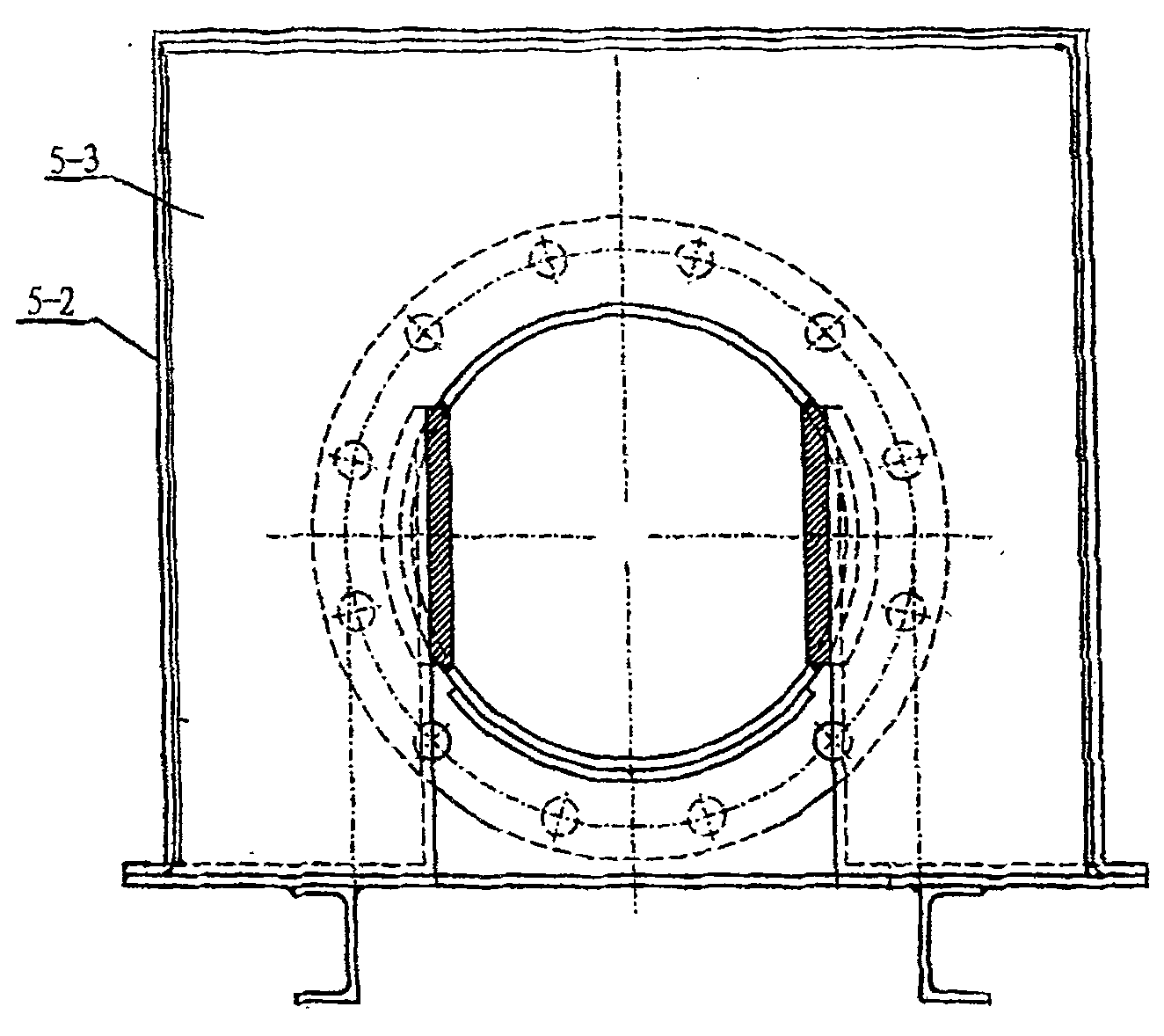

[0024] The present invention is mainly composed of a magnetic field coalescer structure 5 and an electrostatic coalescer structure 6, and is characterized in that the magnetic field coalescer and the electrostatic coalescer structure are designed as an online pipeline structure, which is designed on the module 4 and connected in series in the oil field In the liquid dehydration process, the inlet of the magnetic field coalescer structure is connected to the heating furnace 3 or the buffer tank 2 upstream of the incoming liquid 1, and the outlet is connected to the inlet of the electrostatic coalescer structure; the outlet of the electrostatic coalescer structure is connected to the The inlet of the three-phase separator 7 downstream of the incoming liquid or the inlet of the settling tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com