Novel plant waste residue squeezing and dewatering equipment

A technology for pressing and dehydrating new plants, applied in the direction of presses, manufacturing tools, etc., can solve the problems of cost, inconvenience, difficulty in recycling, etc., and achieve the effect of reducing time and cost, solving dehydration problems, and increasing the content of biological technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

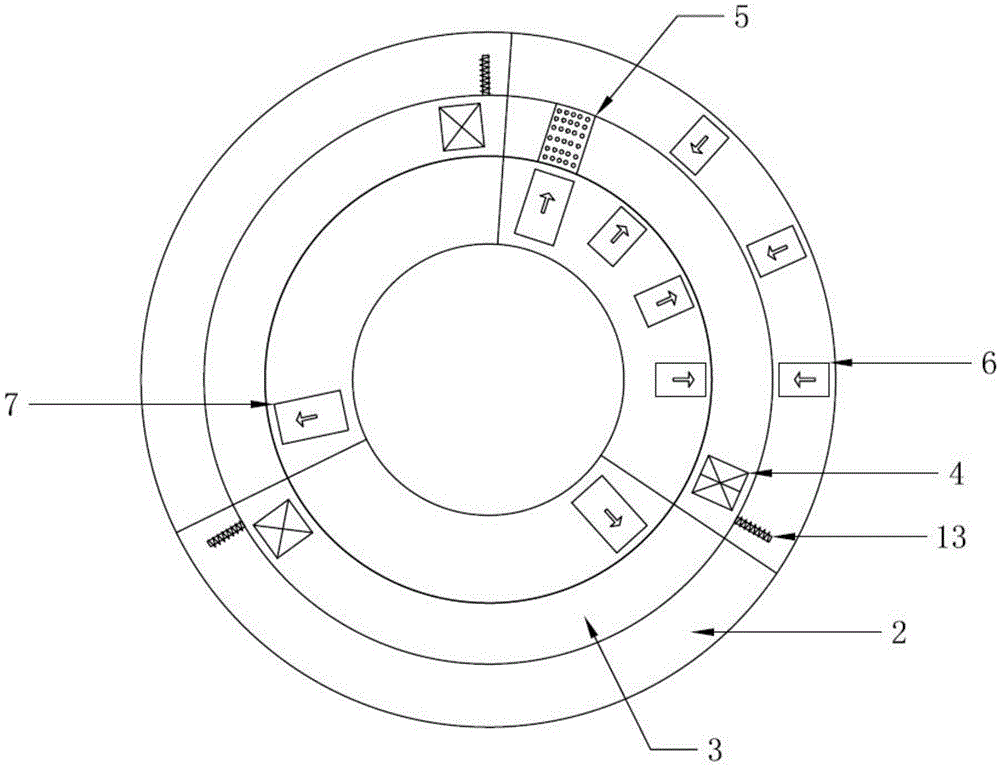

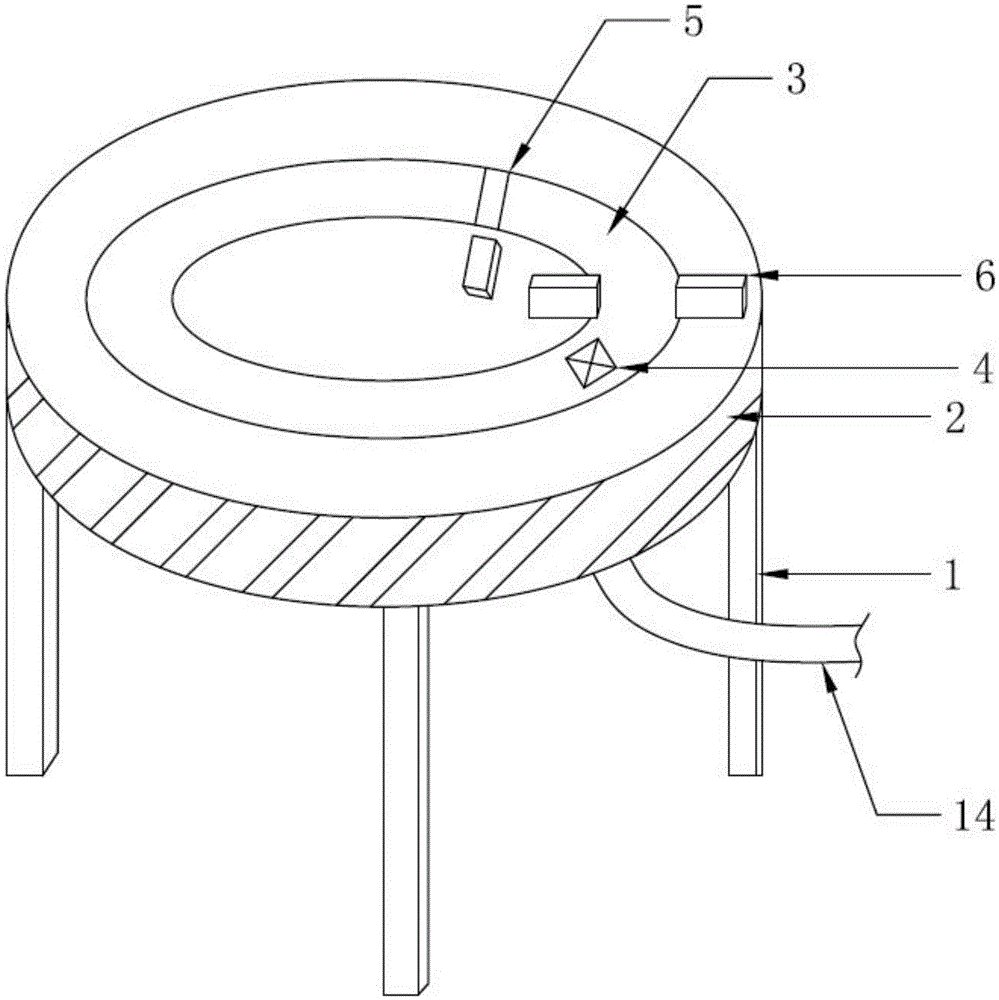

[0023] A new plant waste residue press dehydration equipment, including a frame 1, a fixed disc 2 is arranged on the frame 1, an annular groove is arranged on the fixed disc 2, and an annular turntable 3 is arranged on the annular groove , three groups of feed ports 4 and discharge ports 5 are evenly distributed on the turntable 3, and three groups of extrusion modules 6 are evenly distributed between each group of feed ports 4 and discharge ports 5. The feed ports 4, discharge ports There is a hopper between the feed port 5 and each group of extrusion modules 6, the outer ring of the bottom of the turntable 3 is provided with an annular rack 11, and the inner ring is provided with anti-skid lines 10, and the annular rack 11 is connected to the gap gear 12 , one side of the discharge port 5 is provided with an ejection mechanism 7, the top of each hopper is provided with a hopper door, and the bottom of each hopper is provided with a filter screen.

[0024] The top of the fixe...

Embodiment 2

[0027] This embodiment does not adopt the millstone-type structure in Embodiment 1, but adopts a chain conveying and extruding structure, and hoppers are evenly distributed on the chain, and feed inlet 4, extrusion, and secondary extrusion are arranged in sequence at a fixed position above the chain , a total of three sets of extrusion modules 6 for three times of extrusion, and a discharge port 5, where the extrusion module 6 is for one-way upward extrusion, and an ejection mechanism 7 is provided above the discharge port 5, and below the discharge port 5 The discharge conveyer belt that is provided with horizontal and vertical direction with aforementioned chain is set. This kind of scheme can also be implemented, but the more difficult part is that the positioning accuracy of the hopper is not good enough and the separated moisture is not easy to collect and recycle, and the efficiency and quality are not as high as in Example 1.

Embodiment 3

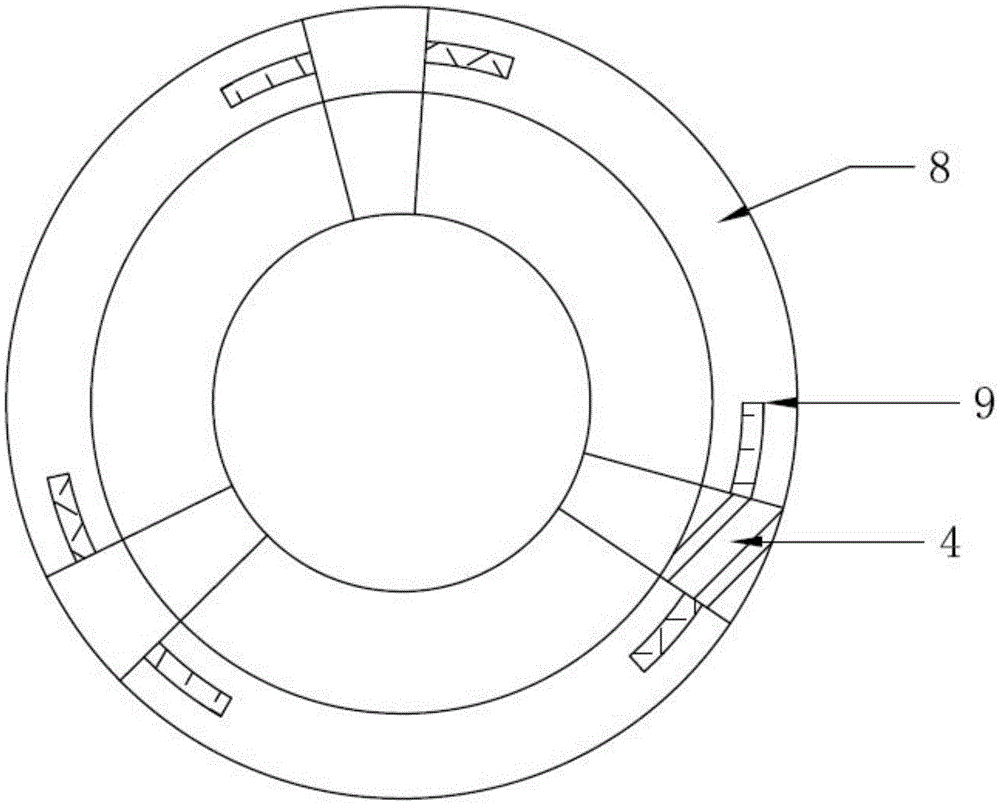

[0029] The difference from Embodiment 1 is that the extrusion module 6 and the ejection mechanism 7 are not fixed on the fixed disc 2, but are rotated synchronously with the turntable 3 and arranged at an inclination. The advantage of this is that the overall structure forms a pot shape, which is beneficial to the collection of detached moisture and more sufficient extrusion dehydration. The difficulty of this embodiment lies in how to prevent all kinds of electric wires from being at least knotted when rotating. Rotary joint, to realize the technical effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com