Engine catalytic converter with novel expansion pipe flow guiding device and sepiolite carrier

A technology of catalytic converter and flow guiding device, which is applied to engine components, machines/engines, mufflers, etc., can solve the problems of small specific surface area, high production cost of catalytic converters, single catalytic reaction, etc., and achieve large specific surface area. , Improve the utilization rate and service life, and eliminate the effect of local flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

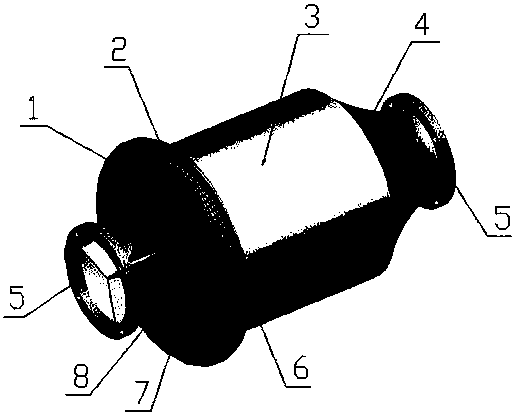

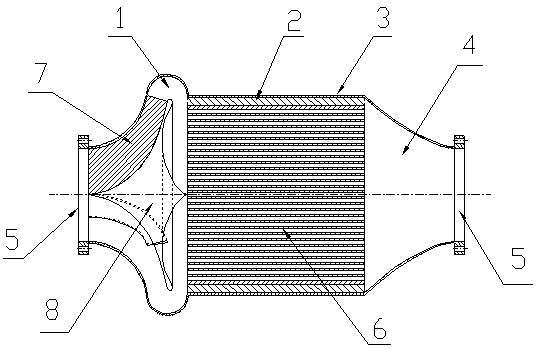

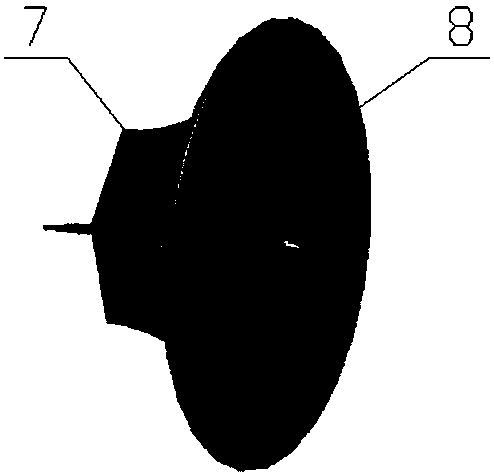

[0021] Such as Figure 1-Figure 4 As shown, a kind of engine catalytic converter that has novel expansion pipe flow guiding device and sepiolite carrier of the present invention is composed of flange 5, expansion pipe 1, flow guiding device 8, fixed rib plate 7, housing 3, shock absorption Layer 2, sepiolite carrier 6 and shrink tube 4; the inlet end of the expansion tube 1 is connected to the flange 5, the inlet end of the expansion tube 1 is connected to the outlet end of the exhaust pipe through the flange, and a flow guiding device is arranged in the expansion tube 1 8. The deflector 8 is located in the expansion tube 1, and is fixed on the inner wall of the expansion tube 1 through the fixed rib plate 7. There are three fixed rib plates 7, the upper long side of which is welded on the inner wall of the expansion tube 1, and the lower long side is welded on the guide tube 1. On the front wall of the flow device 8, the outlet end of the expansion tube 1 is connected to one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com