A novel pyrolysis gasification furnace for organic solid waste

A technology of pyrolysis and gasification of organic solid waste, applied in fixed bed gasification, incinerator, gasification process, etc., can solve the problems of combustible gas containing a large amount of tar, low gasification efficiency, uneven gasification, etc., to achieve Effects of improving energy utilization, reducing tar concentration, and increasing collision frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

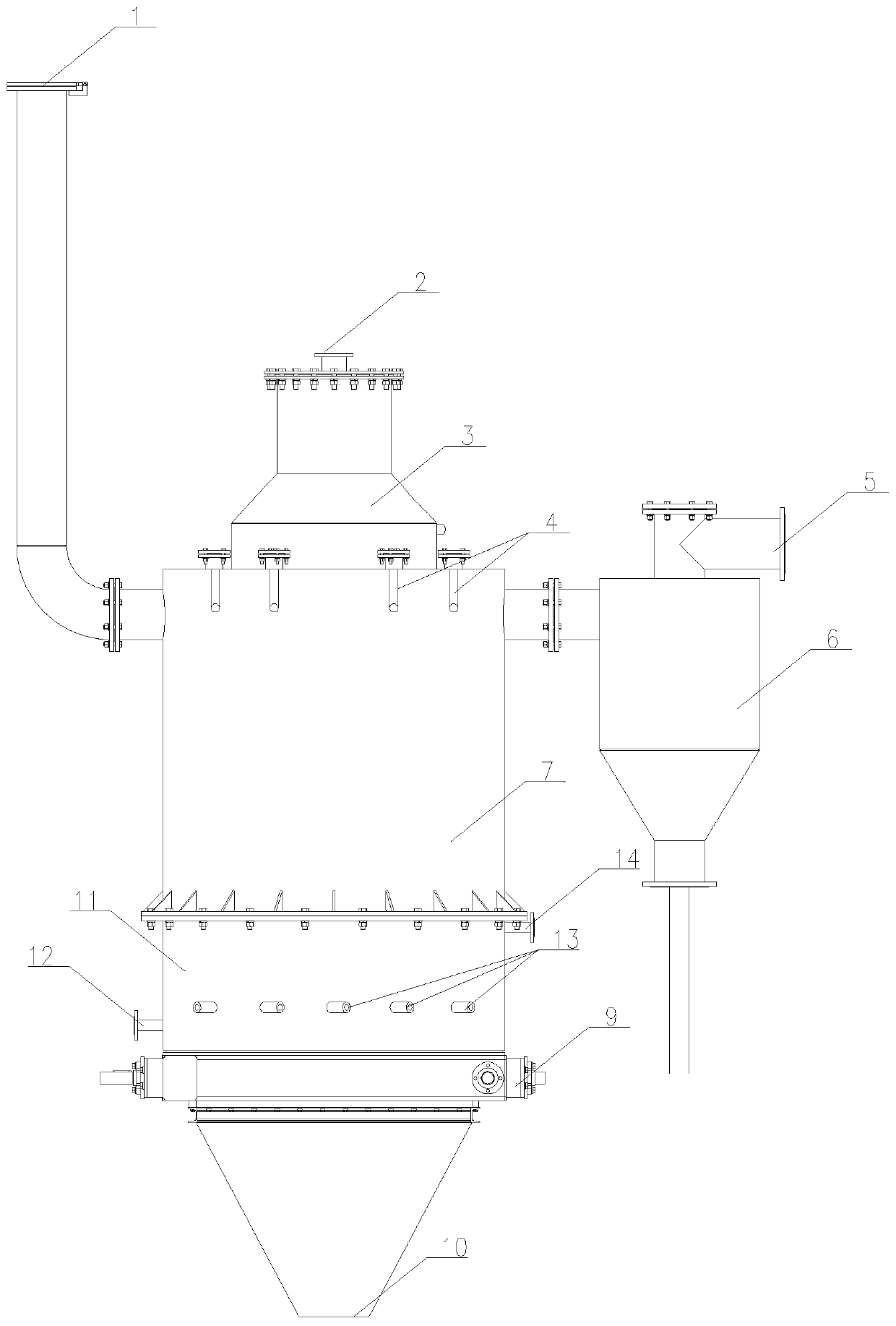

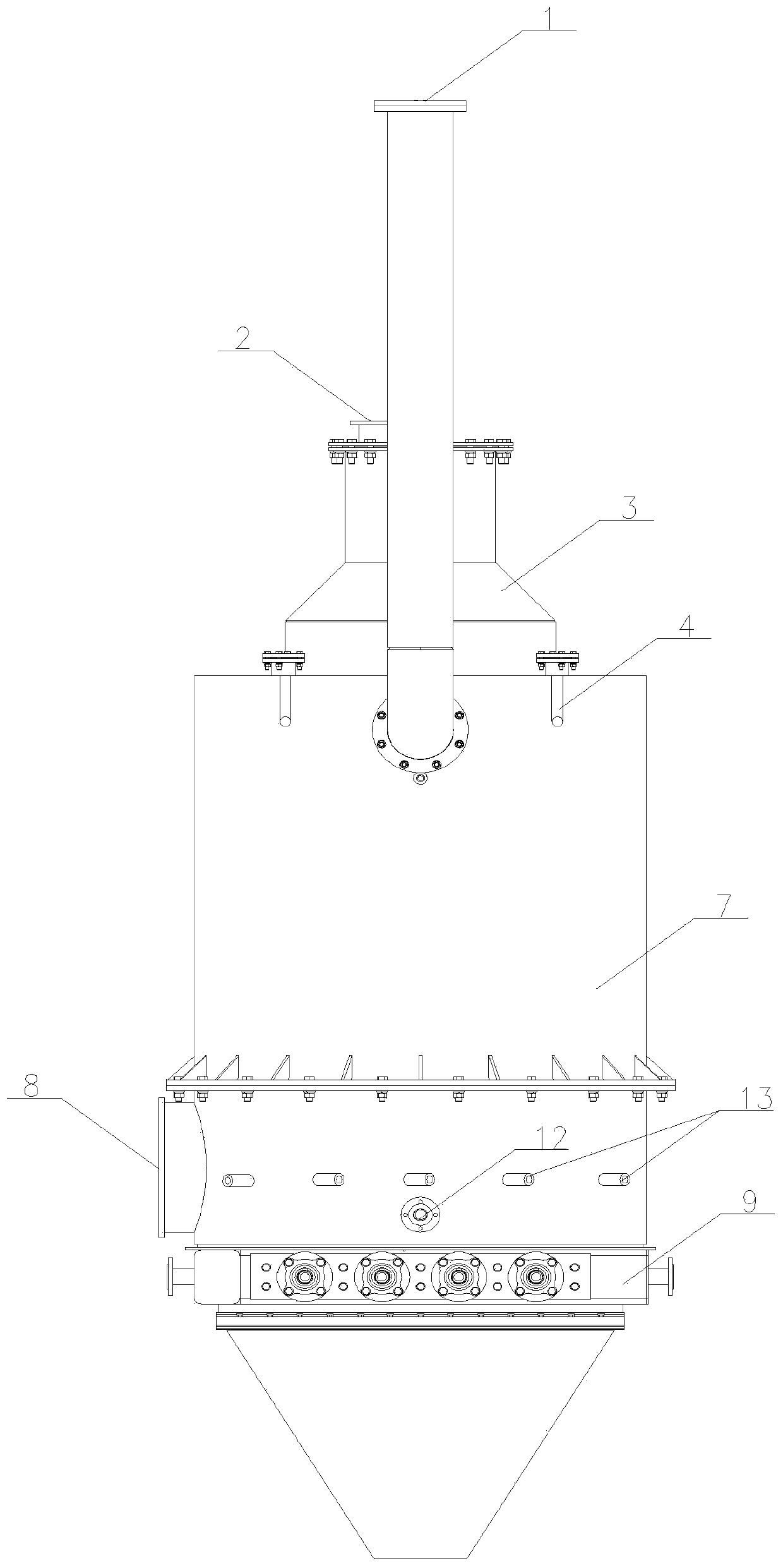

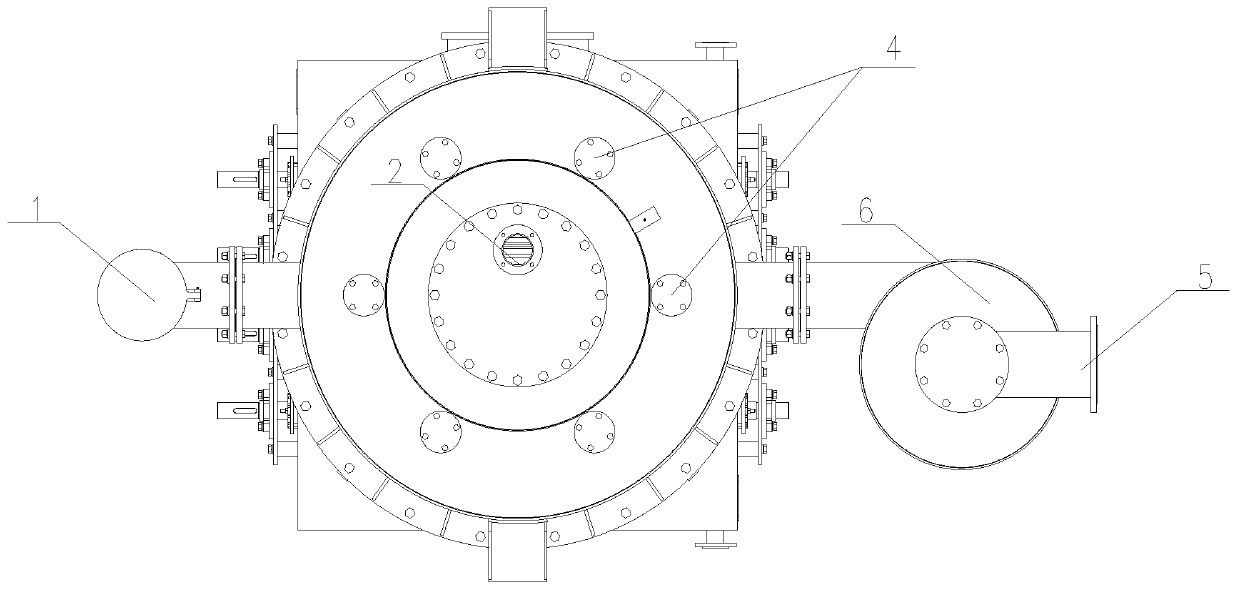

[0026] figure 1 A new type of organic solid waste pyrolysis gasification furnace is shown, the gasification furnace includes a furnace top 3, an upper furnace body 7, a lower furnace body 11, a multi-rotating water-cooled grate 9, and a slag outlet 10 from top to bottom. The interior of the furnace roof 3, upper furnace body 7 and lower furnace body 11 is filled with refractory bricks and refractory materials, and the refractoriness is controlled at about 1200°C; the furnace roof is provided with a feeding port, an observation port and an atomized spray structure, , the atomizing spray structure includes 6 atomizing spraying devices 4 uniformly distributed on the furnace top, all of which are supplied with water by a circulating water pump, and each atomizing spraying device 4 is equipped with a nozzle and a pneumatic valve, and each atomizing spraying device 4 is equipped with a nozzle and a pneumatic valve. The spraying device is independently controlled by a pneumatic valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com