Radial flow equalization pressure swing adsorption tower

A pressure swing adsorption and adsorption chamber technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of unreasonable airflow distribution, uneven flow field distribution, large flow resistance, etc., and achieve improved gas production. Efficiency and gas production quality, uniform flow field distribution, reasonable airflow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

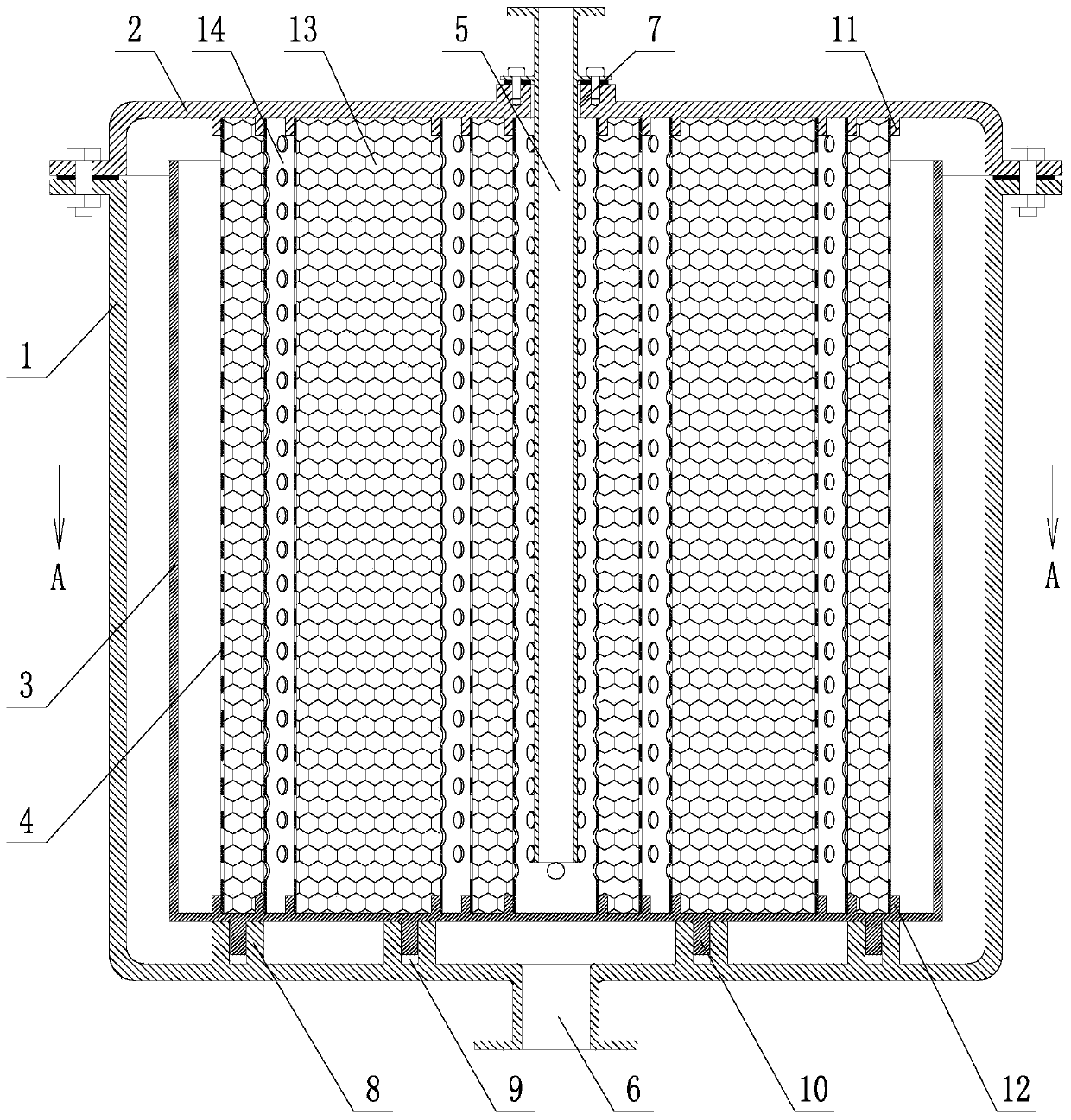

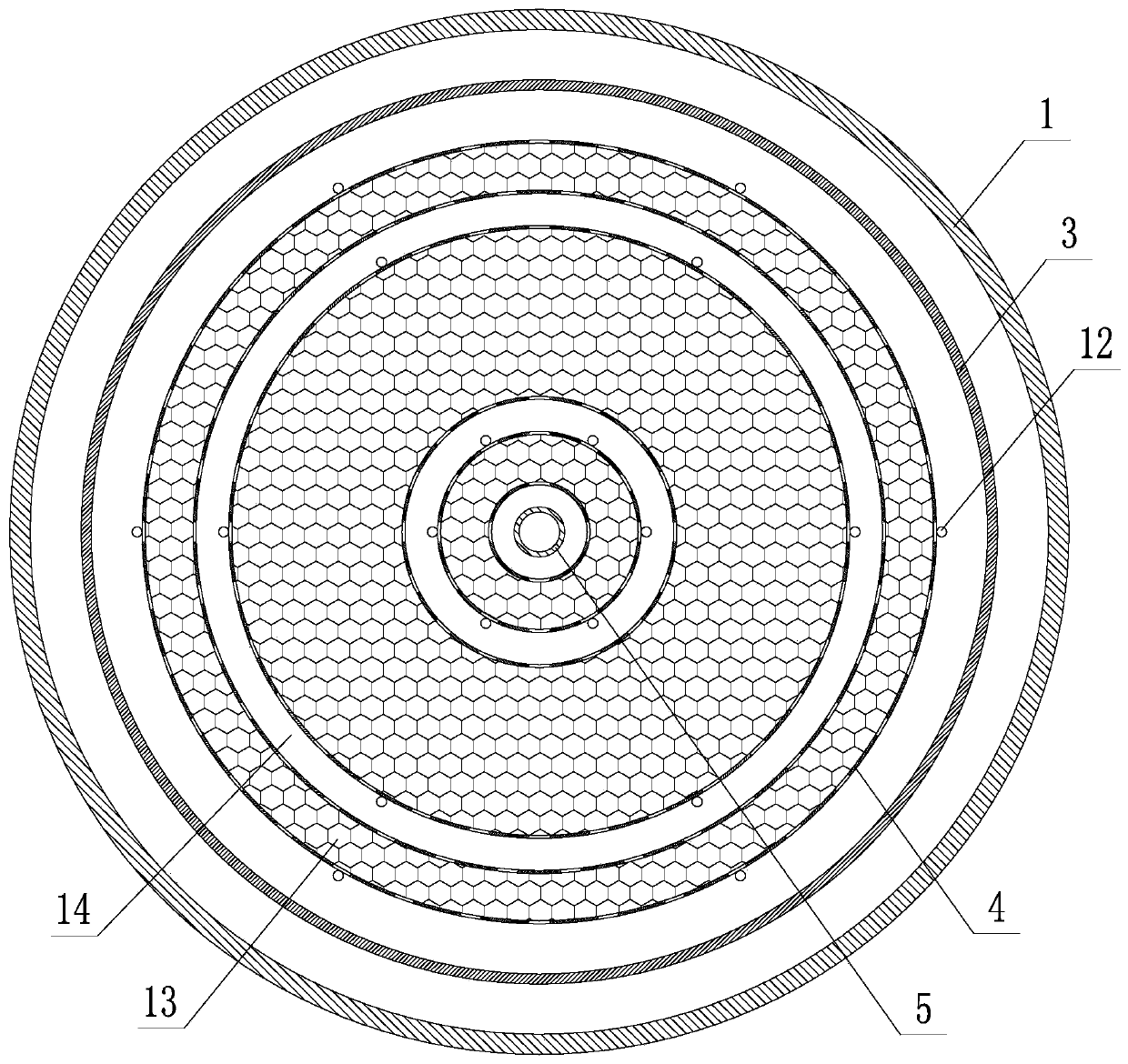

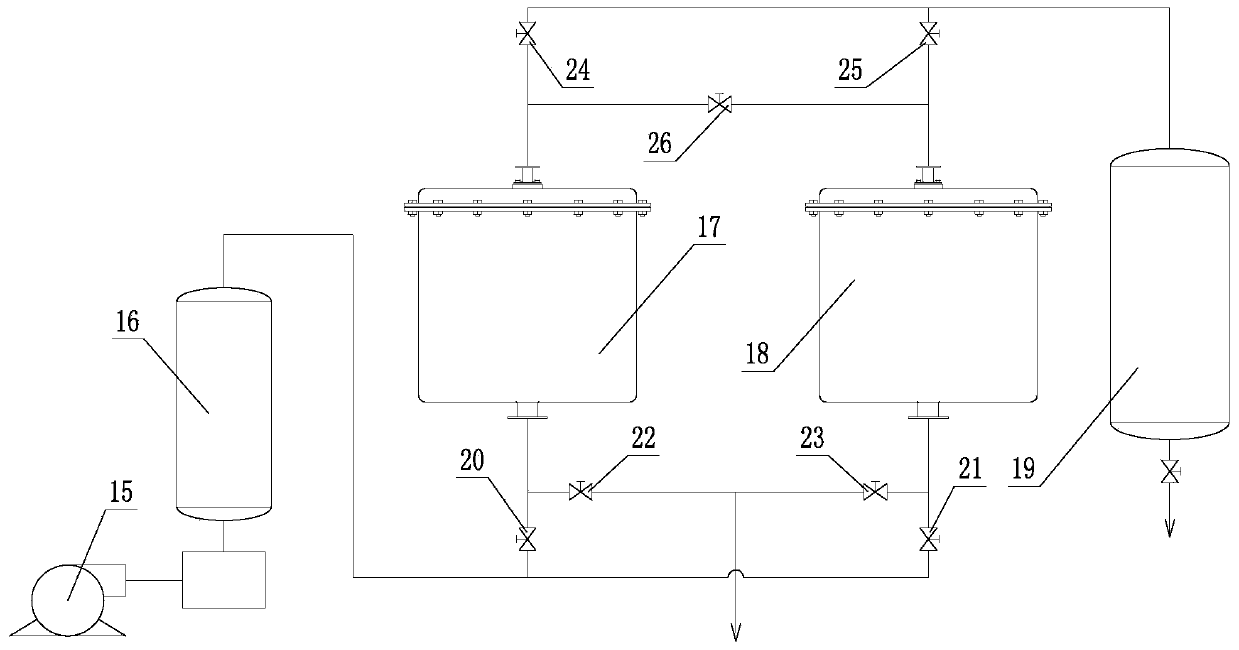

[0018] Such as figure 1 , 2 As shown, a radial flow equalization and pressure swing adsorption tower includes a shell 1, a cover 2, a guide tube 3, an air distribution tube 4 and a ventilation pipe 5; the shell 1 adopts a cylindrical structure, and the shell 1 is vertical The center of the bottom plate of the shell 1 is provided with a vent 6, the top of the shell 1 is an open structure, and the cover 2 is sealed and fixed on the top opening of the shell 1; hole 7, the vent pipe 5 is vertically inserted in the vent pipe jack 7, the pipe body of the vent pipe 5 is sealed and fixedly connected with the vent pipe jack 7, the lower end nozzle of the vent pipe 5 is located inside the shell 1, and the vent pipe 5. The nozzle at the upper end is located outside the cover 2; a number of support blocks 8 are provided on the upper surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com