A multi-unit composite spiral plate heat exchanger

A spiral plate type, heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, laminated components, etc., can solve the problem of difficult real-time monitoring of the effectiveness of internal structures, difficult to obtain local blockages in real time, and difficult heat exchange plate depth. Cleaning and other problems, to achieve the effect of easy modular expansion, easy modular processing and assembly, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

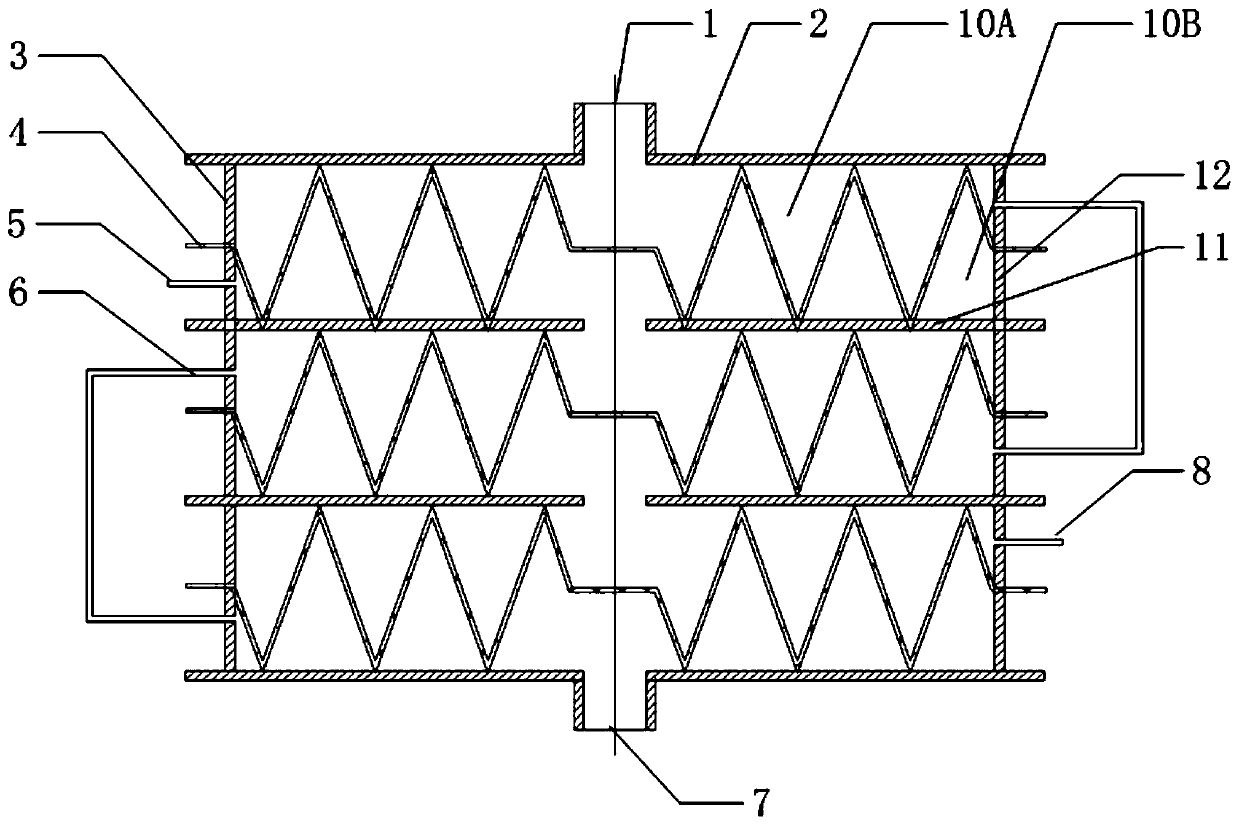

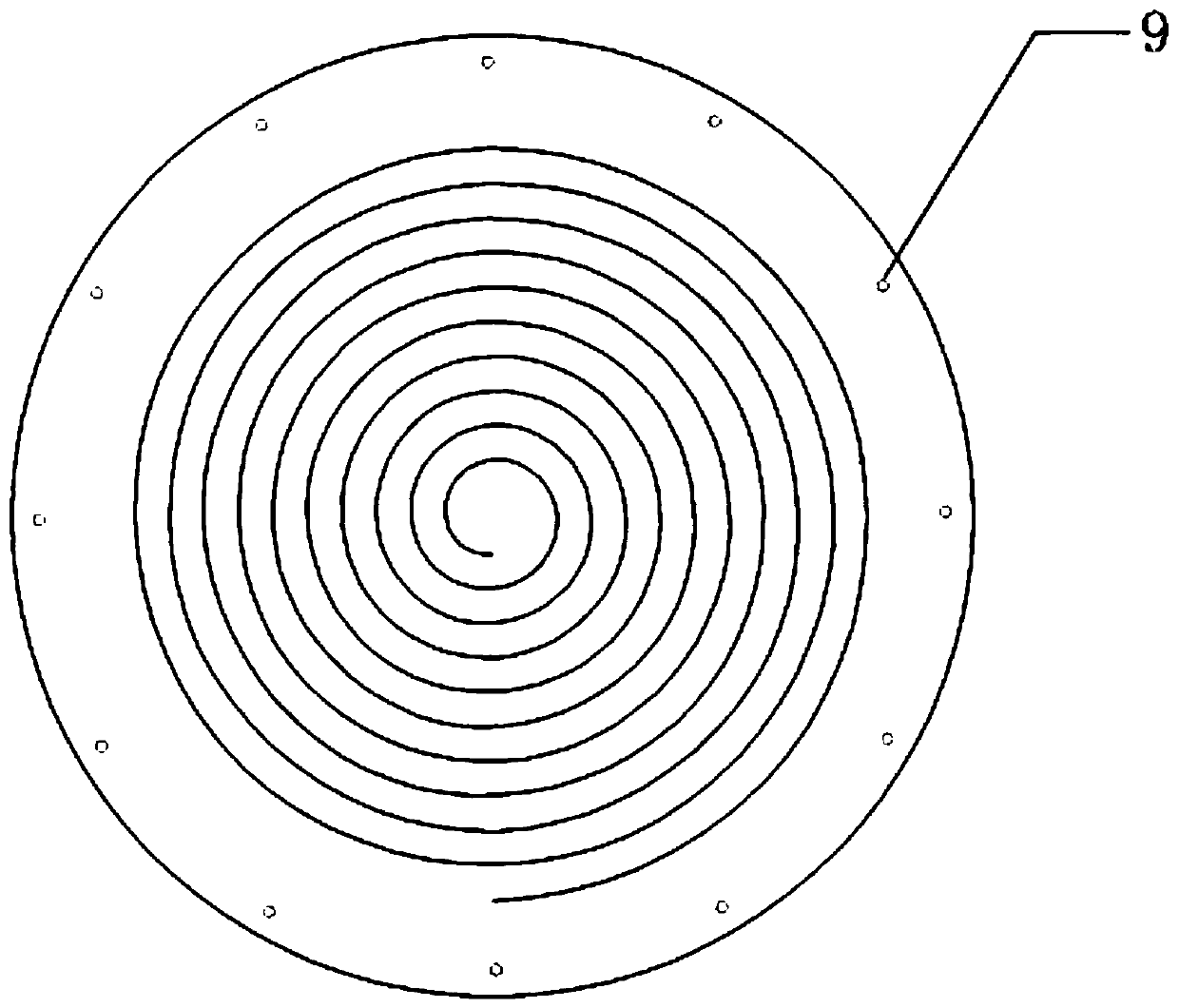

[0027] This embodiment discloses a multi-unit composite spiral plate heat exchanger. Such as figure 1 and figure 2 As shown, the multi-unit composite spiral plate heat exchanger includes a plurality of vertically stacked heat exchange units. The heat exchange unit includes a metal plate 4 with a spiral groove, an upper cover plate 2 with a central hole, and a central hole. The lower cover plate 11, and the first side plate 3 provided with the first fluid port and the second side plate 12 provided with the second fluid port. The heat exchange unit is divided into an upper flow channel 10A and a lower flow channel 10B by the metal plate 4, and the upper flow channel 10A and the lower flow channel 10B are both spiral. The edge of the metal plate 4 with the spiral groove is a planar structure, and is provided with a plurality of connection holes 9 . A plurality of connection holes are provided at the edges of the upper cover plate 2 and the lower cover plate 11 . The bottom s...

Embodiment 2

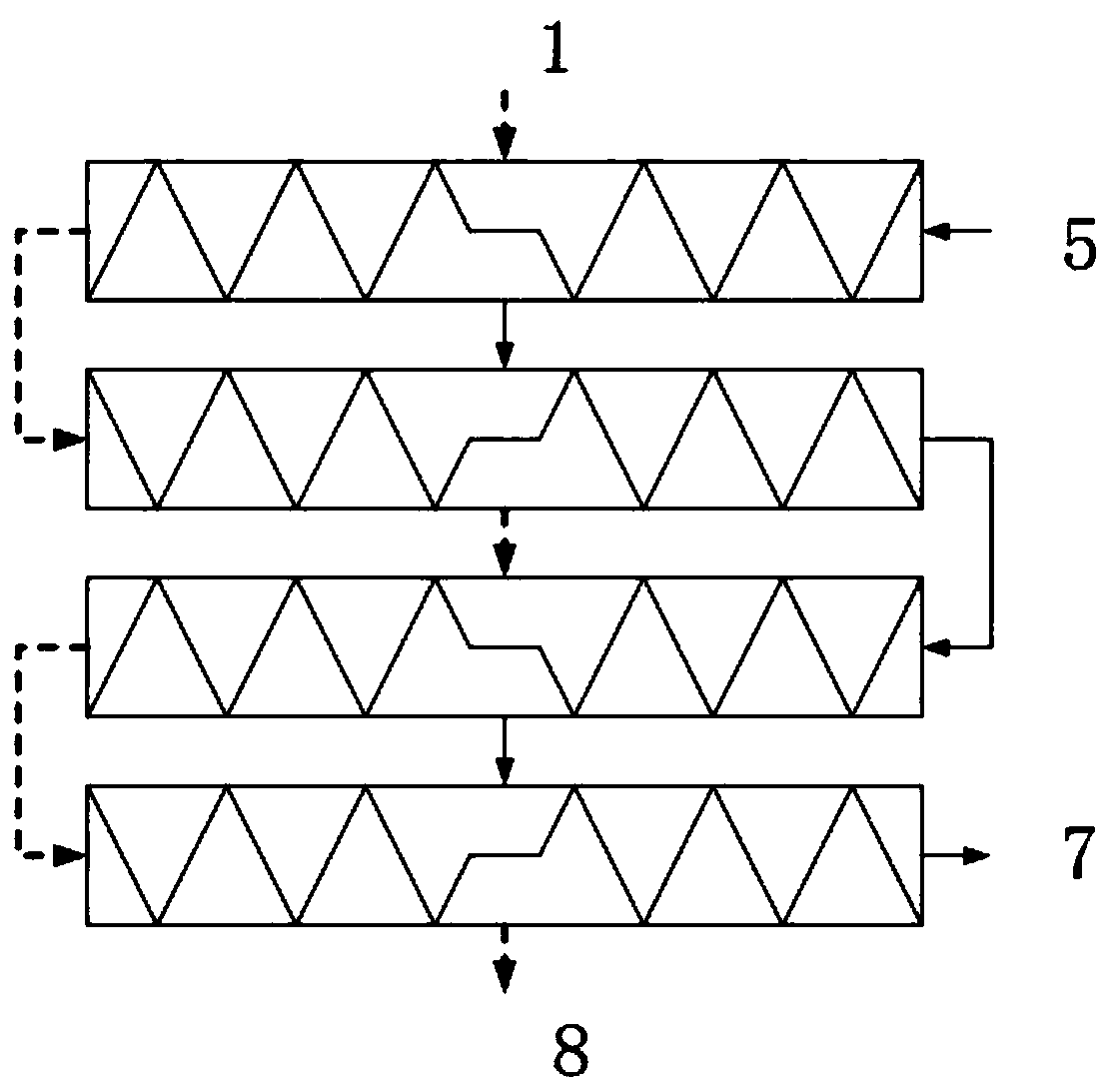

[0031] In this embodiment, the structure of the same multi-unit composite spiral plate heat exchanger as in Embodiment 1 will not be repeated, and the parallel flow heat exchange or countercurrent heat exchange in this embodiment will be described in detail below.

[0032] see Figure 4 , as shown by the dotted line in the figure, the flow direction of the hot-side fluid is consistent with that of Example 1. The hot-side fluid flows in from the hot-side fluid inlet 1 in the center of the first heat exchange unit, and flows through the first heat exchange unit from the inside to the outside. The spiral upper flow channel flows into the spiral lower flow channel of the second heat exchange unit through the side connecting pipe, and flows through the spiral lower flow channel from outside to inside, and then passes between the second heat exchange unit and the third heat exchange unit The central hole of the shared cover plate flows into the spiral upper flow channel of the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com