Supergravity-fractal impact bed reactor

A reactor and impact bed technology, which is applied in the field of multiphase flow mixing and reaction reaction devices, can solve the problems of difficult to handle systems with high viscosity materials and solid-phase materials, difficulties in industrial scale up, and narrow flow channels, etc. The number of power equipment and pipe fittings, improving disordered mixing, and the effect of small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

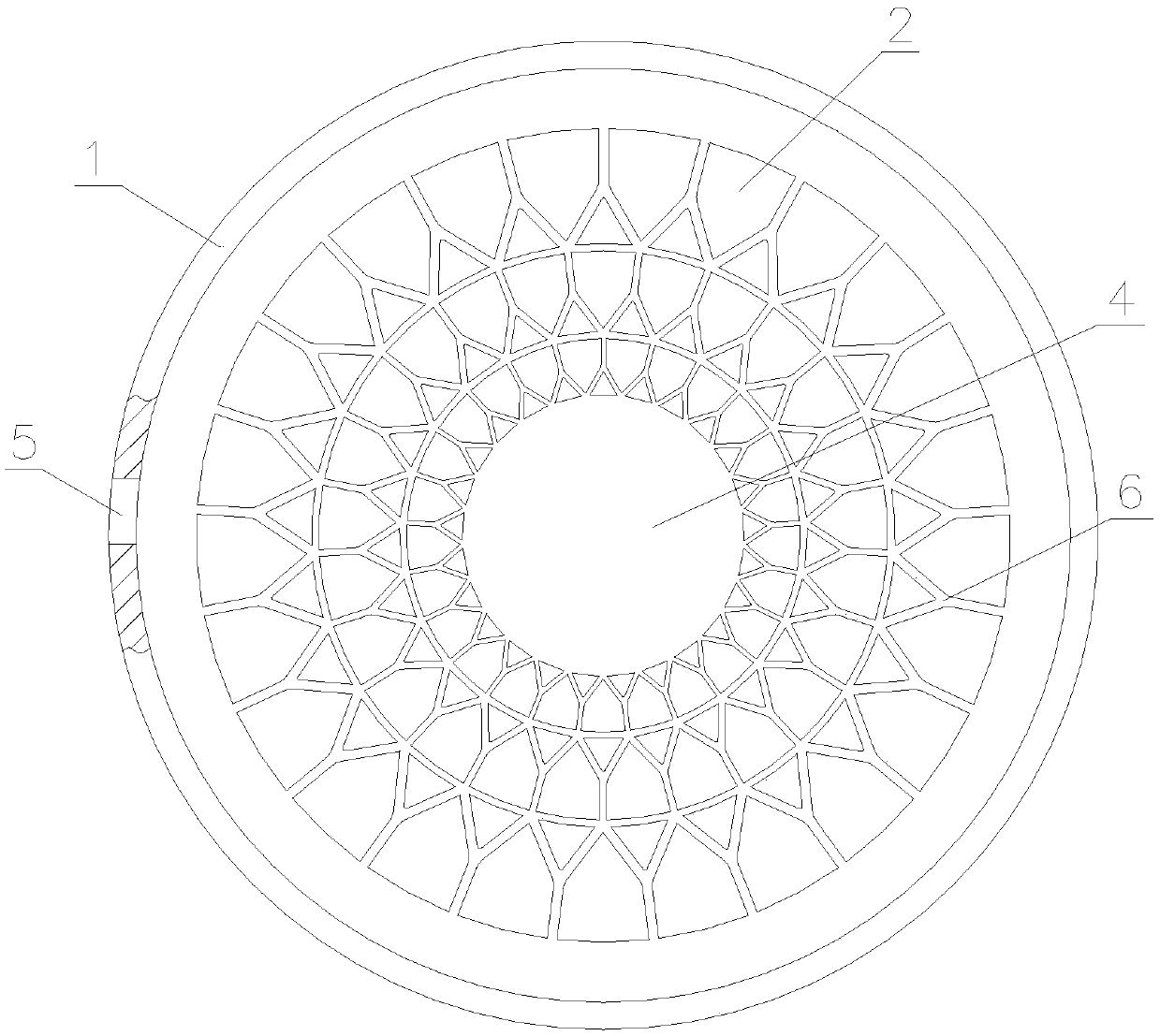

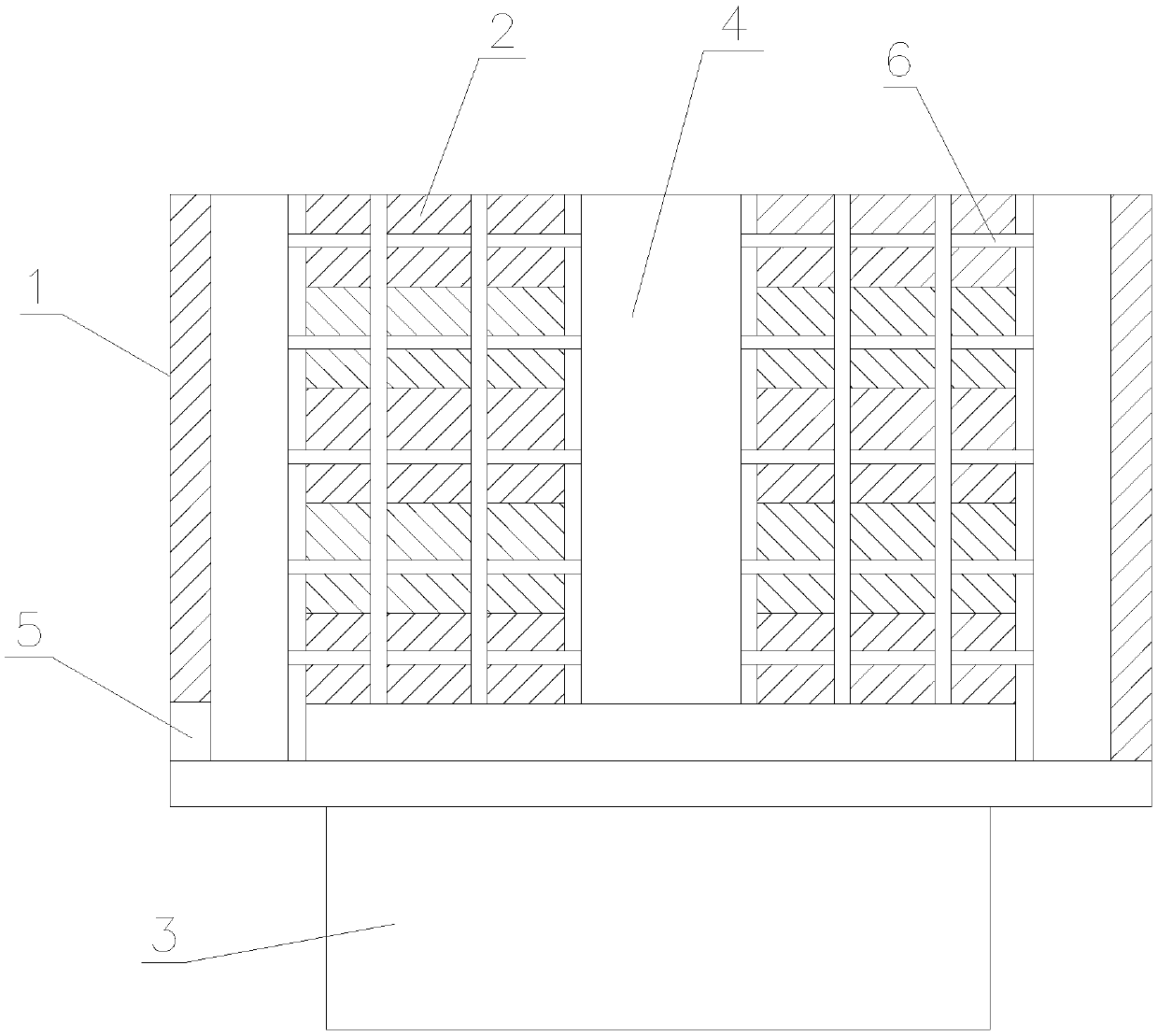

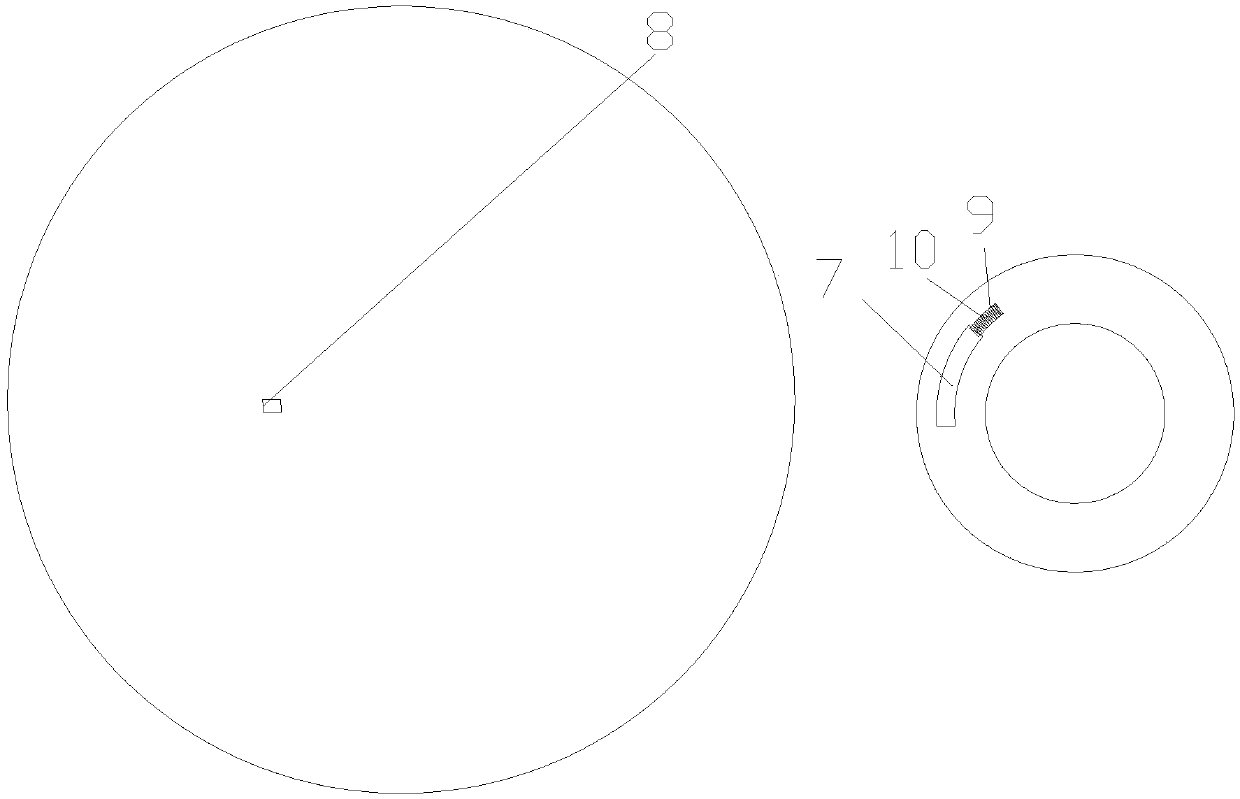

[0028] Such as Figure 1-Figure 3

[0029] A high-gravity-fractal impacted-bed reactor, mainly comprising a cylindrical shell 1 and a rotating cylinder 2 assembled by three layers of fractal ring pieces, a tray is placed below the rotating cylinder, and the tray is connected to an external centrifuge 3. The center of the rotating cylinder is provided with a feed inlet 4, and the cylindrical shell is provided with a fluid outlet pipe 5. The inside of the fractal ring sheet is provided with a fractal passage 6 that penetrates step by step in the radial direction, and the fractal ring sheet The fractal series of the internal fractal passage is 15≥n≥3, and the diameter of the fractal passage is 1 μm to 0.5m; the diameter of the n-1 fractal passage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com