Plate radiator unit box for double-sloping-shoulder transformer

A technology for transformers and radiators, applied in the direction of transformer/inductor cooling, etc., can solve problems such as poor heat dissipation, and achieve the effects of novel structure, sufficient heat exchange, and uniform flow field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

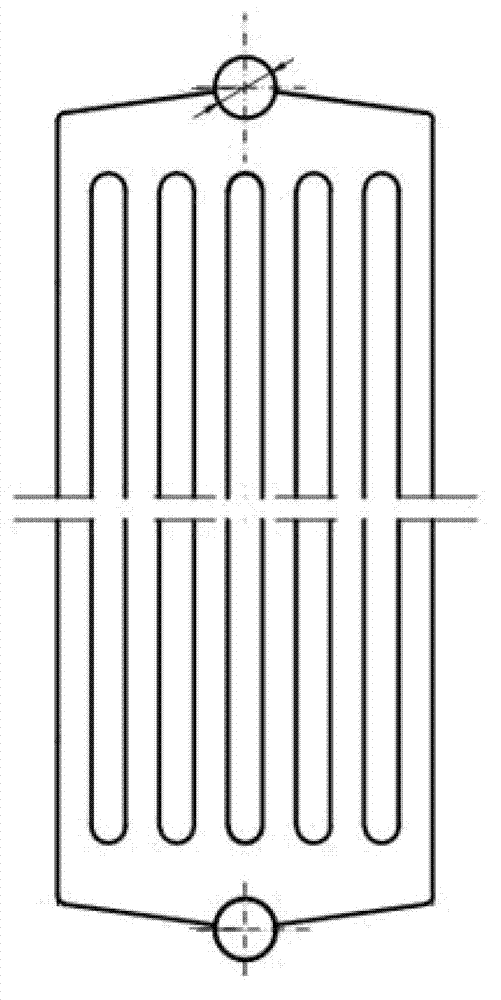

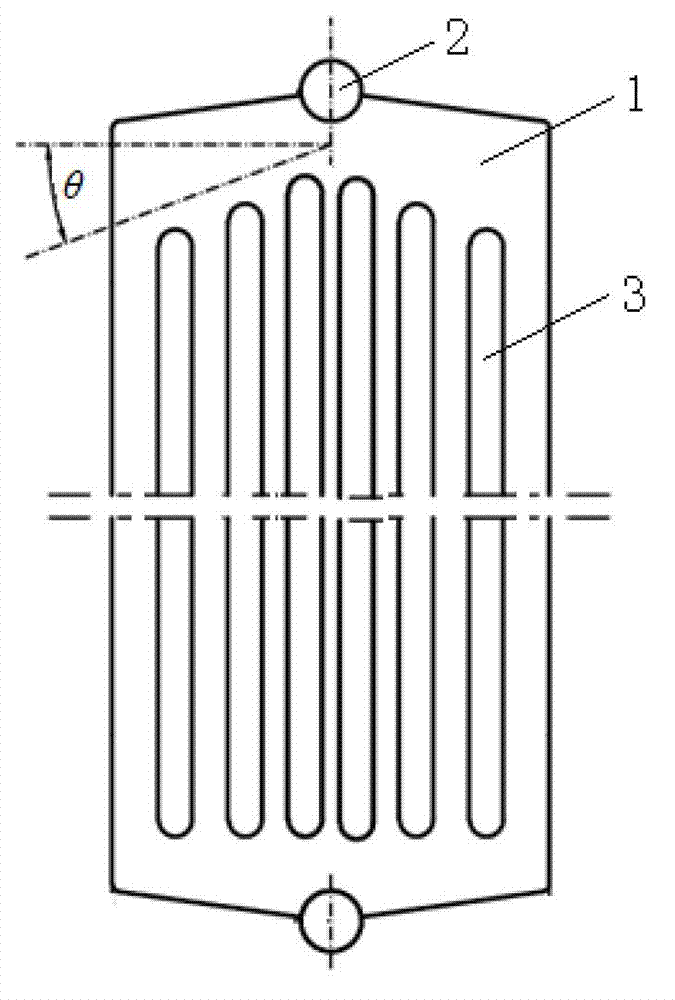

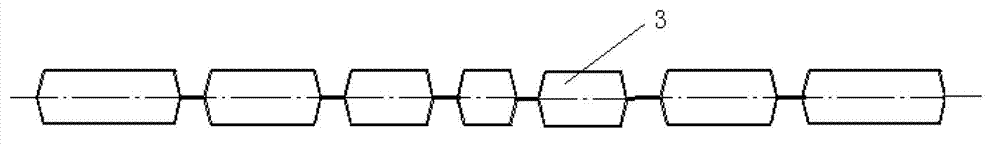

[0031] On the top and bottom of the main body 1, there are oil collecting pipe inlet and outlet 2 respectively, and there is an oil passage 3 inside the main body. The middle part of the oil passage is a high point, and the inclination angle to both sides θ for 13 o ;The width of the oil passage gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =3mm.

Embodiment 2

[0033] On the top and bottom of the main body 1, there are oil collecting pipe inlet and outlet 2 respectively, and there is an oil passage 3 inside the main body. The middle part of the oil passage is a high point, and the inclination angle to both sides θ for 13 o ;The width of the oil passage gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =6.5mm.

Embodiment 3

[0035] On the top and bottom of the main body 1, there are oil collecting pipe inlet and outlet 2 respectively, and there is an oil passage 3 inside the main body. The middle part of the oil passage is a high point, and the inclination angle to both sides θ for 13 o ;The width of the oil passage gradually increases from the middle to both sides according to the arithmetic sequence, and the tolerance d =10mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com