Fluidized-bed fly ash back-to- furnace gasification apparatus and method

A gasification equipment and fluidized bed technology, applied in the field of coal gasification, can solve the problems of short circuit, biased flow in the gasifier, and inability to return ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

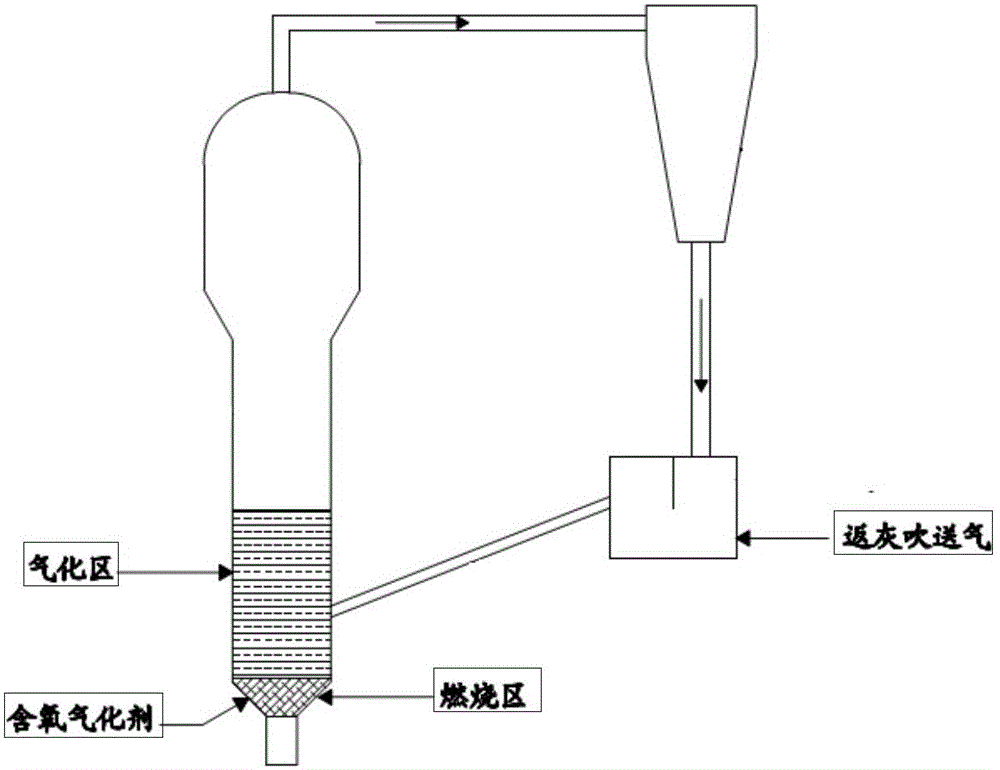

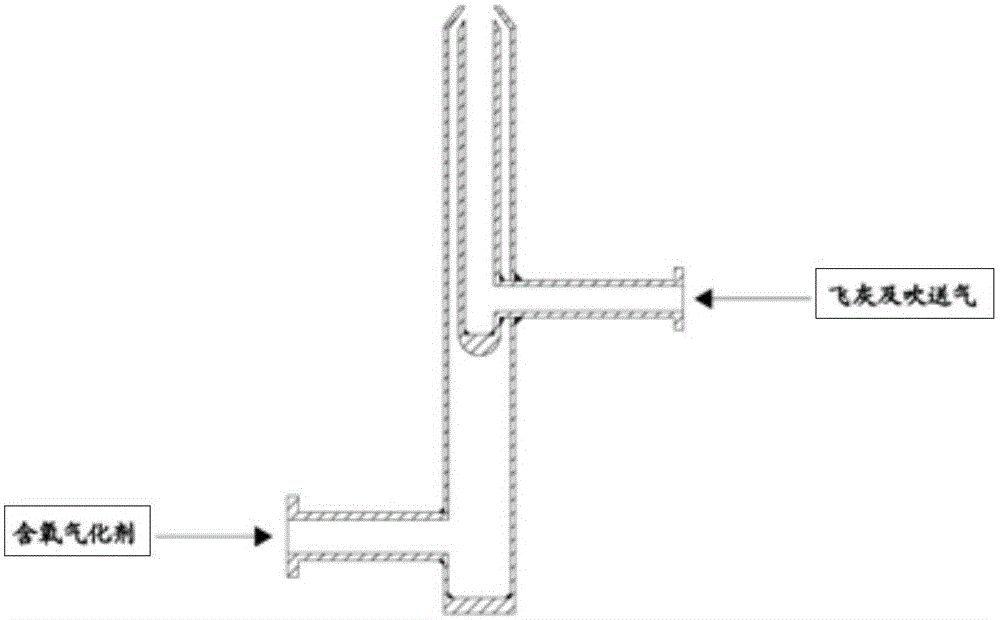

[0061] use as Figure 4 The shown fluidized bed fly ash return furnace gasification equipment, wherein the fly ash injection device used is as figure 2 As shown, that is, the inner channel is used to feed the mixture of fly ash and returned ash blowing gas, the outer channel is used to feed the oxygen-containing oxidant, and the airflow of the oxygen-containing oxidant mixed with fly ash is injected into the lower part of the gasifier, namely in the combustion reaction zone.

Embodiment 2

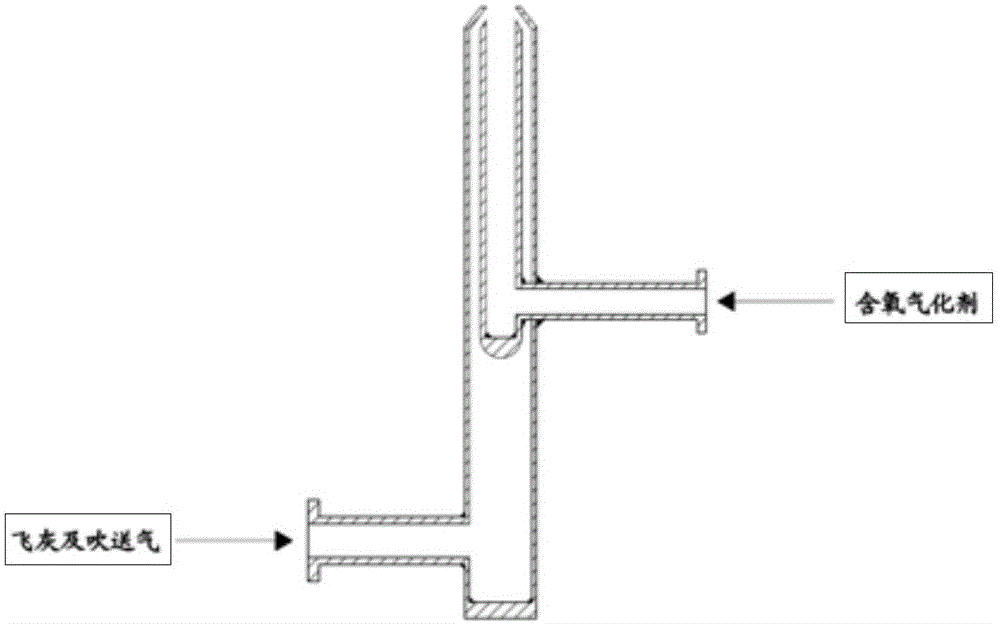

[0063] use as Figure 4 The shown fluidized bed fly ash return furnace gasification equipment, wherein the fly ash injection device used is as image 3 As shown, that is, the inner channel is used to pass through the oxygen-containing oxidant, and the outer channel is used to pass through the mixture of fly ash and blown gas. in the reaction zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com