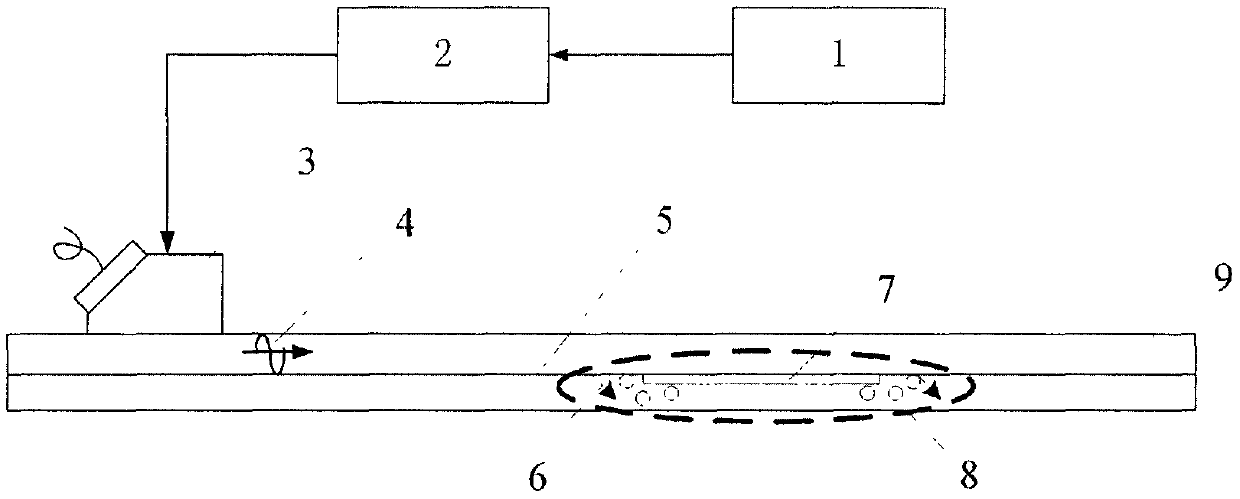

Surface descaling method based on multi-frequency leaked ultrasonic guided waves

A technology of multi-frequency ultrasound and ultrasonic guided wave, which is applied in cleaning methods and utensils, chemical instruments and methods, and can solve problems such as production interruption and small removal range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] 1. Frequency selection test

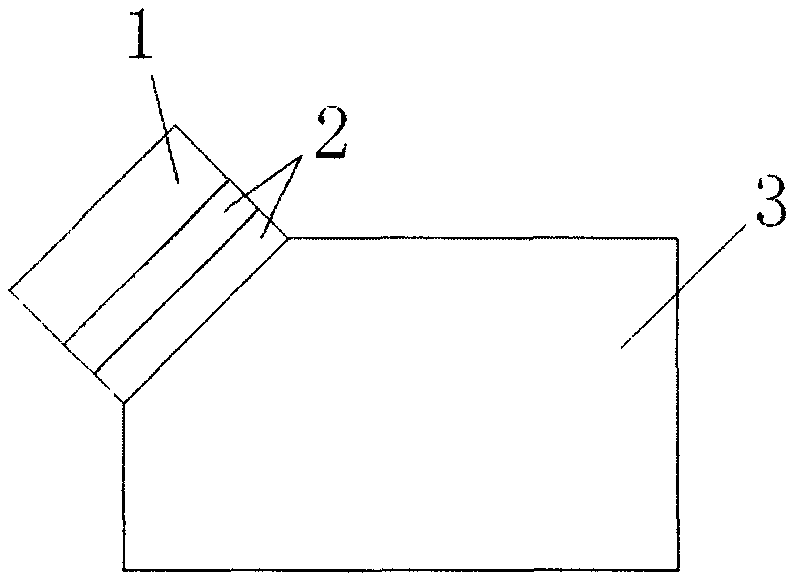

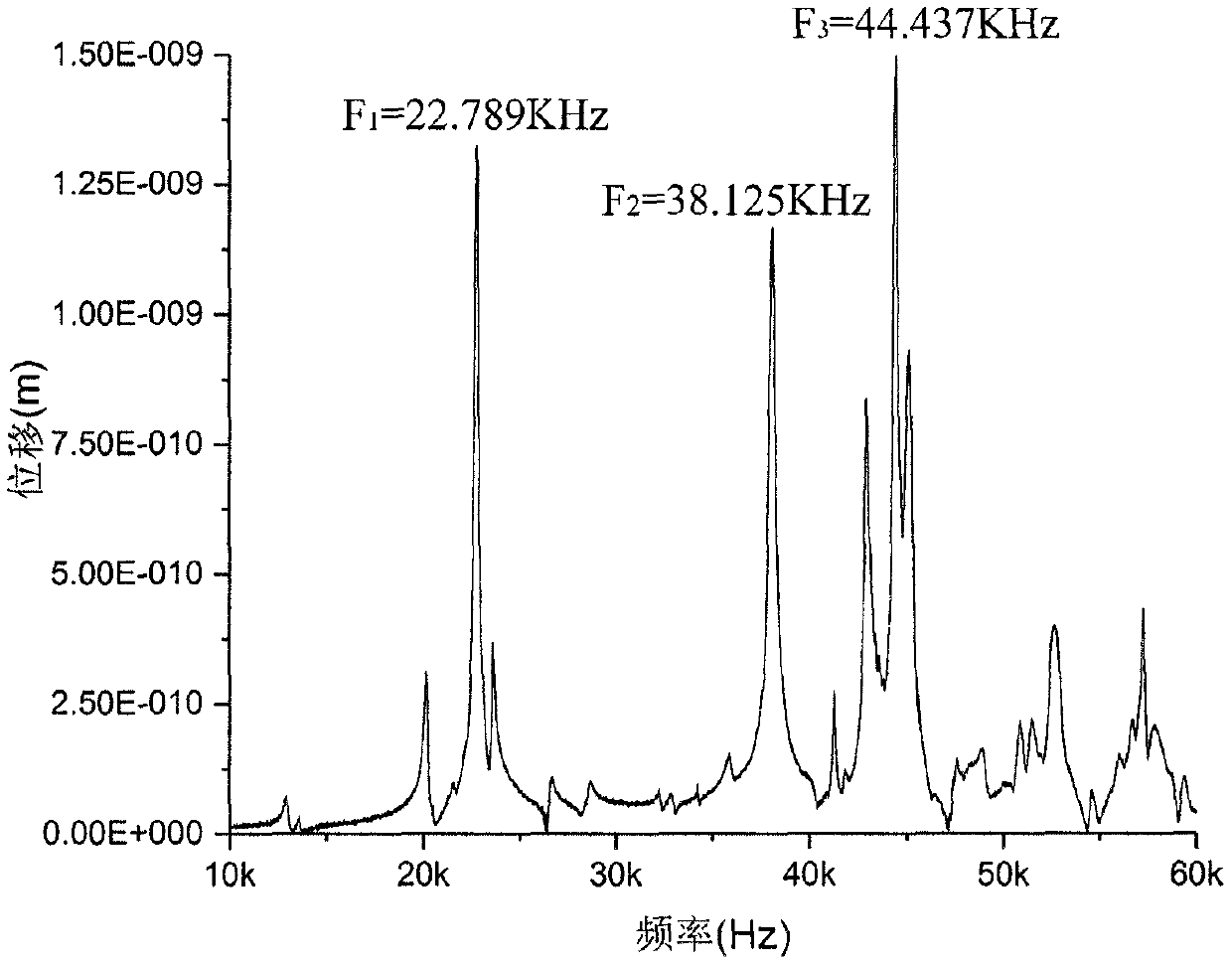

[0021] With a single oblique incidence transducer, such as figure 2 shown. The transducer, which consists of an aluminum square base and piezoelectric material, was first tested using a laser scanning vibrometer. The sweep frequency signal generated by the signal generator is input to the oblique transducer, and the scanning laser vibrometer is tested and FFT (fast Fourier transform) is performed to obtain the displacement vibration characteristics of the transducer at different frequencies, and the displacement-frequency characteristics of the transducer curve like image 3 shown. According to the test results, the transducers have displacement peaks at frequencies of 22.789KHz, 38.125KHz and 44.437KHz respectively, and the transducers have good electro-acoustic conversion efficiency at the peak frequencies. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com