Long-service-life synthetic oil special for wind power gears and preparation method thereof

A long-life, special-purpose oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high temperature rise, short service life, high friction coefficient, etc., achieve low friction coefficient, effectively absorb shock and vibration, and excellent anti-friction performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

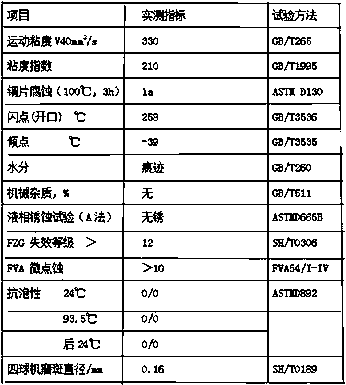

Image

Examples

Embodiment

[0015] Example: A long-life synthetic wind power gear special oil, prepare 850kg of PAG220, 150kg of polyester KL2500, 8kg of octyl / butyl liquid diphenylamine, 8 kg of 2,6-p-di-tert-butyl-p-cresol, and benzotriazole Fatty amine salt 2 kg, molybdenum dialkyldithiosulfate 20 kg, tricresyl phosphate 10 kg, condensate of amine and epoxy oxide 0.1 kg, composite antifoaming agent 0.01 kg, metal deactivator 3 kg, fatty acid ester 20 kg.

[0016] Production method: (1), put polyether and polyester into the reaction kettle, heat up to 60°C, and stir for 10 minutes;

[0017] (2) Put PAG (220) and polyester KL2500 into the reaction kettle, raise the temperature to 67°C, stir for 10 minutes, then put in sequentially octyl / butyl liquid diphenylamine, 2,6-p-di-tert-butyl p- Cresol, benzotriazole fatty amine salt, molybdenum dialkyldithiosulfate, tricresyl phosphate, condensate of amine and epoxy oxide, metal deactivator, fatty acid ester, compound antifoaming agent, constant temperature 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com