Dual-scale micro-structure artificial bone scaffold and preparation method thereof

A technology of microstructure and artificial bone, applied in scaffolds, bone implants, medical science, etc., can solve problems such as poor nutrient transport function, high porosity, etc., to ensure integrity, ensure continuous supply, and evenly distribute the flow field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

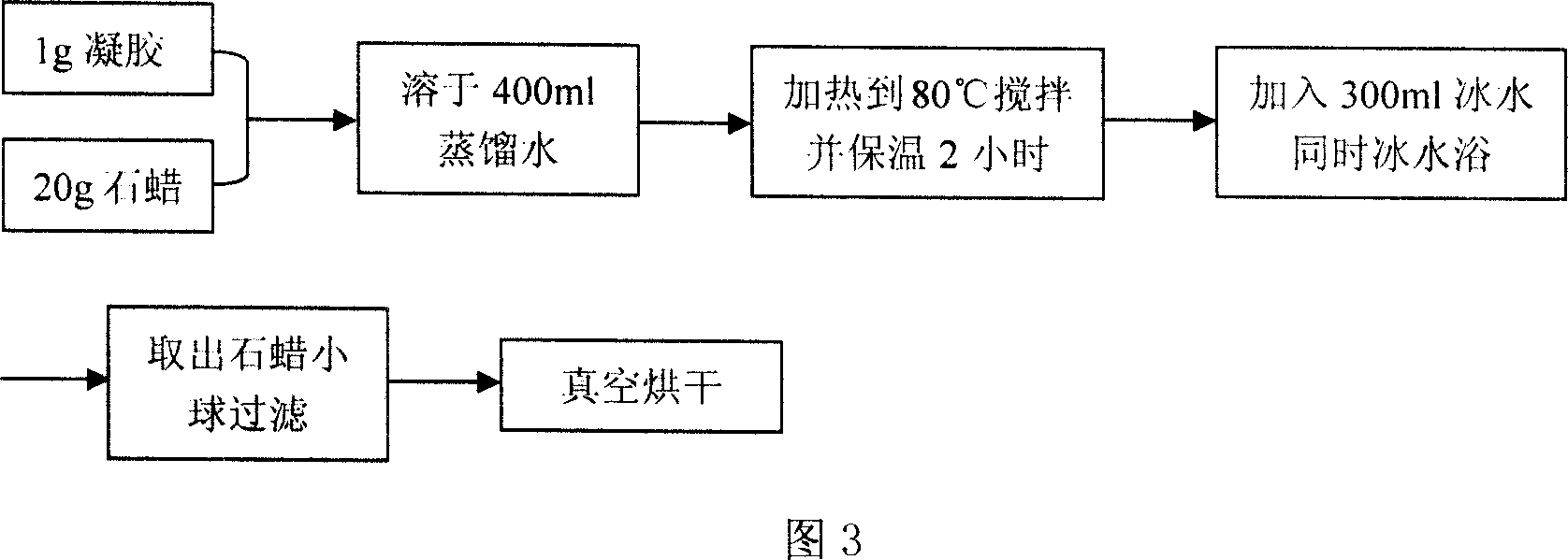

[0026] Embodiment one: the concrete steps of the present invention are as follows:

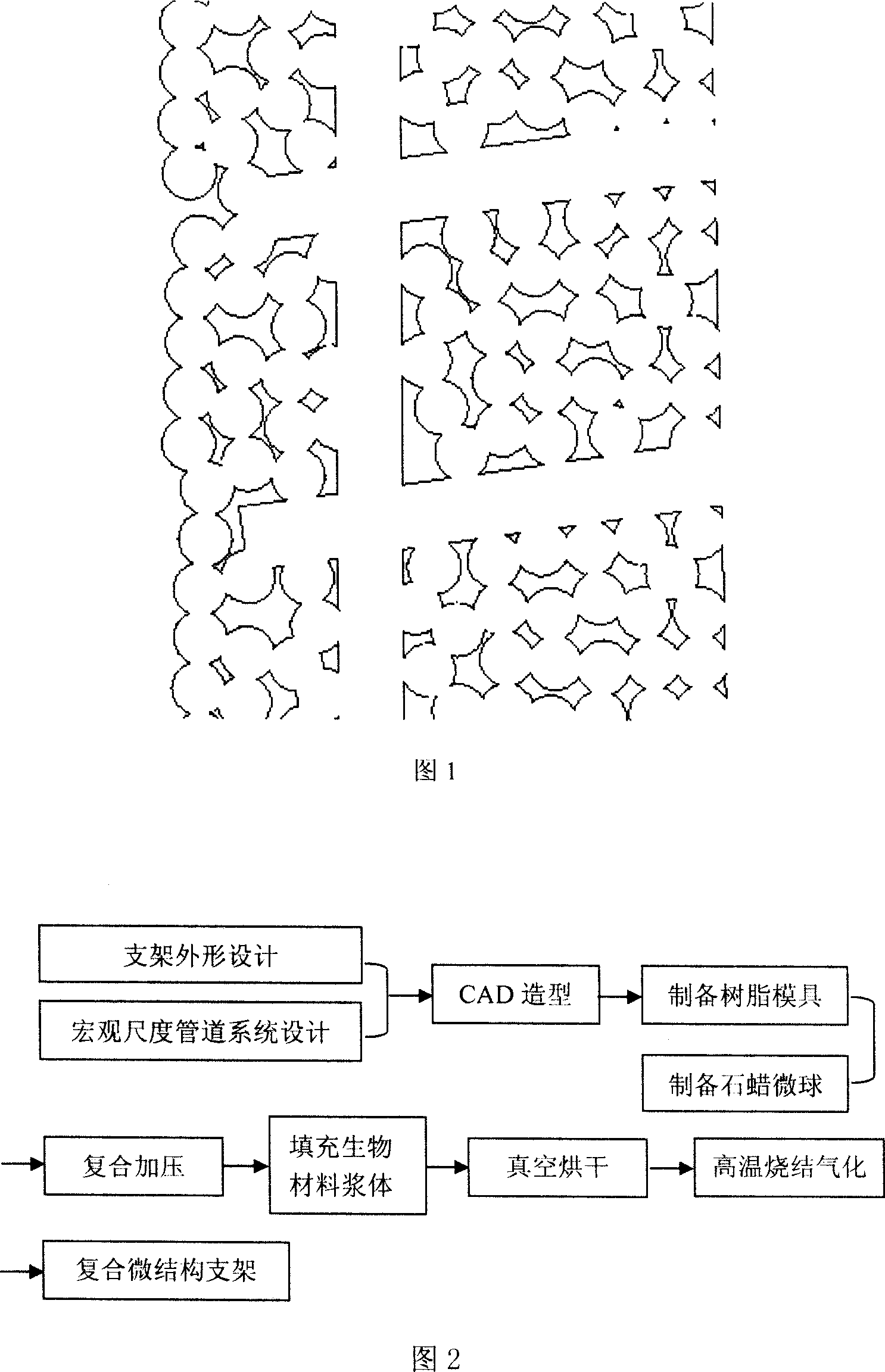

[0027] 1) Obtain the shape data of the scaffold through CT scanning or directly design the shape of the scaffold through CAD software, design the internal microstructure of the scaffold using CAD software, and then combine the shape of the scaffold with the internal microstructure data to form a CAD with the negative shape of the macroscale pipeline artificial bone scaffold Model;

[0028] 2) Convert the CAD model data containing the negative shape of the macroscale pipeline artificial bone scaffold into an STL file format, and use the rapid prototyping layering software Rpdata for layered slice processing to generate the default format file of the light-curing rapid prototyping equipment, and the format file is input to In the light-curing rapid prototyping equipment, the resin mold containing the macro-scale pipe bracket is prepared by the light-curing rapid prototyping equipment;

[0029] ...

Embodiment 2

[0031] Embodiment two: the concrete steps of the present invention are as follows:

[0032] 1) Obtain the shape data of the scaffold through CT scanning or directly design the shape of the scaffold through CAD software, use CAD software to design the internal microstructure of the scaffold, and then combine the scaffold shape and internal microstructure data to form a CAD with the negative shape of the macroscale pipeline artificial bone scaffold Model;

[0033] 2) Convert the CAD model data containing the negative shape of the macro-scale pipeline artificial bone scaffold into an STL file format, and use the rapid prototyping layering software Rpdata for layered slice processing to generate the default format file of the light-curing rapid prototyping equipment, and the format file is input to In the light-curing rapid prototyping equipment, the resin mold containing the macro-scale pipe bracket is prepared by the light-curing rapid prototyping equipment;

[0034]3) Prepare ...

Embodiment 3

[0036] Embodiment three: the concrete steps of the present invention are as follows:

[0037] 1) Obtain the shape data of the scaffold through CT scanning or directly design the shape of the scaffold through CAD software, design the internal microstructure of the scaffold using CAD software, and then combine the shape of the scaffold with the internal microstructure data to form a CAD with the negative shape of the macroscale pipeline artificial bone scaffold Model;

[0038] 2) Convert the CAD model data containing the negative shape of the macroscale pipeline artificial bone scaffold into an STL file format, and use the rapid prototyping layering software Rpdata for layered slice processing to generate the default format file of the light-curing rapid prototyping equipment, and the format file is input to In the light-curing rapid prototyping equipment, the resin mold containing the macro-scale pipe bracket is prepared by the light-curing rapid prototyping equipment;

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com