Rod baffle heat exchanger

A baffle rod and heat exchanger technology, which is applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of large fluid flow resistance, vibration and wear of heat exchange tubes, leakage of heat exchange tubes, etc. Achieve the effect of not easy to deposit, eliminate lateral scour, and reduce shear stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The device structure and working process of the baffle rod heat exchanger will be described in detail below through specific embodiments.

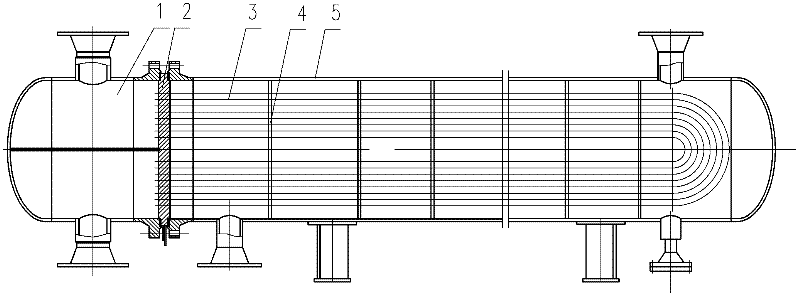

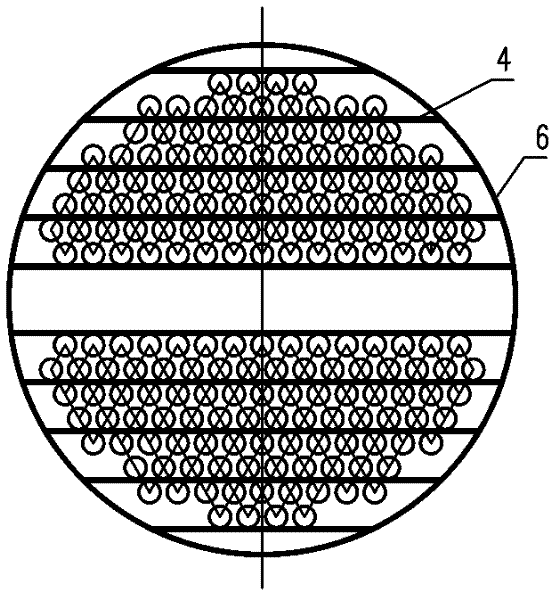

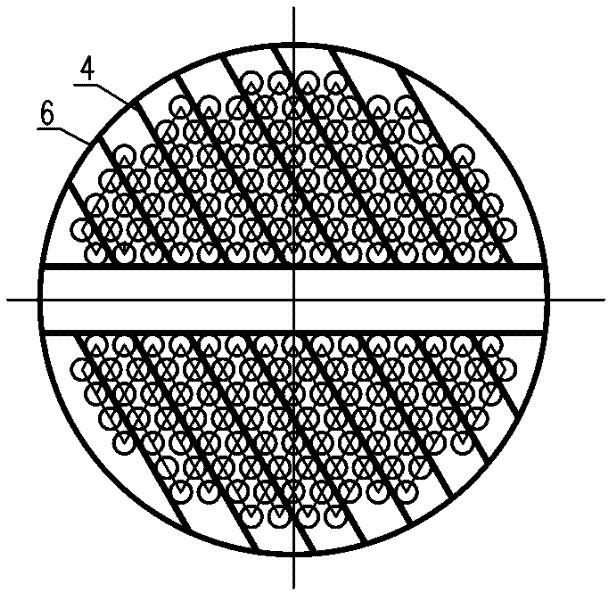

[0015] See figure 1 , Figure 2-a , Figure 2-b , Figure 2-c , Figure 2-d , one A baffle rod heat exchanger, including a tube box 1, a tube sheet 2, a heat exchange tube 3, a baffle rod 4, a shell 5, and a baffle ring 6, which are perpendicular to the axial direction of the shell 5 in the shell 5 A plurality of baffle grids are arranged at intervals in the direction of the baffle grid. The baffle grids are composed of mutually parallel baffle rods 4 welded on the baffle ring 6. The heat exchange tube bundle passes through the baffle rods 4. The diameter or thickness of the baffle rods It is exactly equal to the gap between two adjacent rows of heat exchange tubes; the direction of the baffle rods in the adjacently arranged baffle grids is different, so that every time the shell-side fluid passes through a baffle grid, a turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com