Detachable modular wear-resistant ash-removal three-dimension finned tube type heat exchanger

A heat exchanger, modular technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve economic losses, hinder heat exchange between cold and hot media, change the rated heat load of heat exchangers, etc. problems, to achieve uniform distribution of flue gas flow field, avoid economic losses, and promote the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

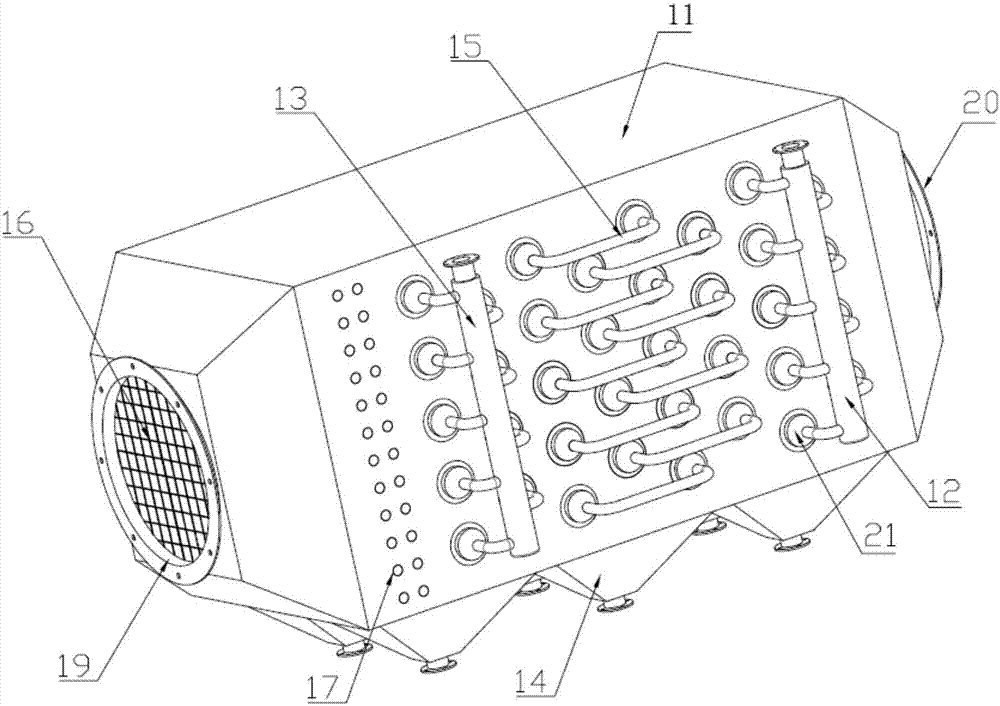

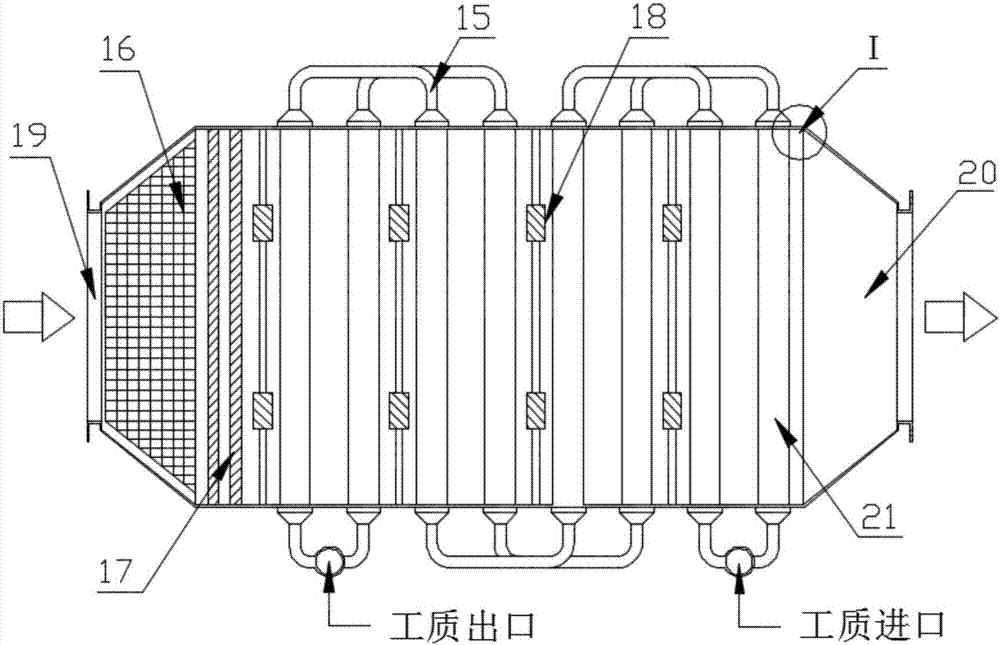

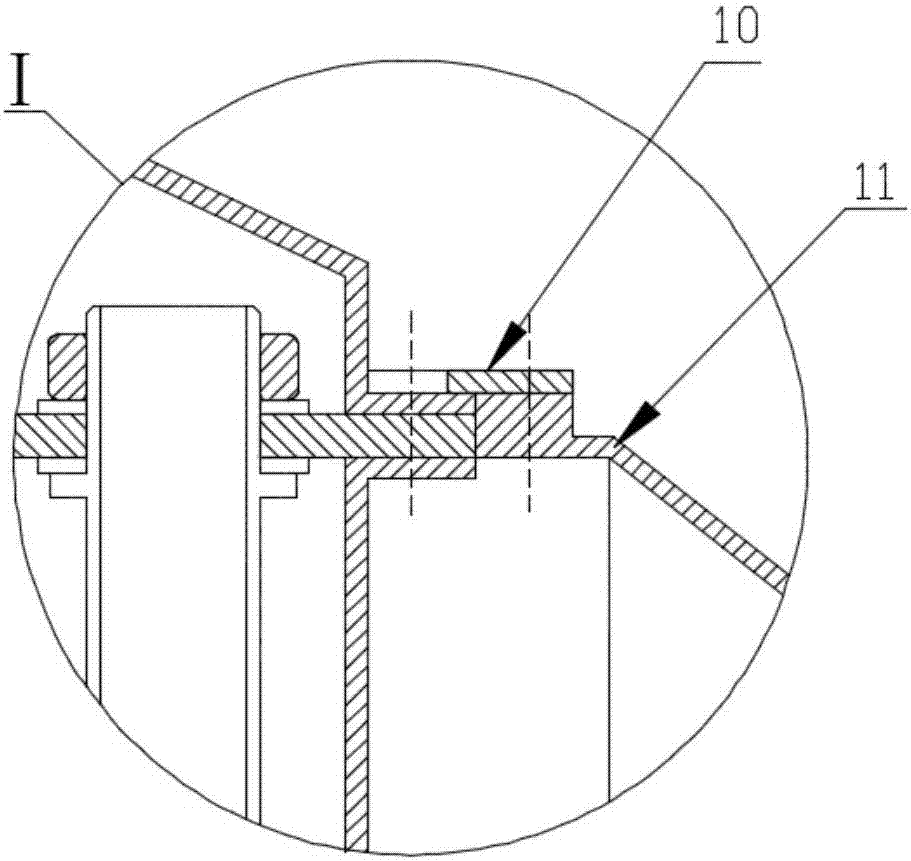

[0025] see Figure 1 to Figure 8, a detachable modular anti-wear and dust-removing three-dimensional finned tube heat exchanger, including a heat exchanger shell 11 connected to the flue; an air inlet 19 is arranged on the front plate of the heat exchanger shell 11, and An air outlet 20 is arranged on the end plate; the air inlet 19 is connected to the outlet of the high-temperature flue, and the air outlet 20 is connected to the inlet of the low-temperature flue; the lower end plate of the heat exchanger shell 11 is provided with a tapered ash removal port 14; A refrigerant inlet header 12 and a refrigerant outlet header 13 are arranged outside the heat exchanger housing 11; a rectification grid 16 is arranged at the end of the air inlet 19 in the heat exchanger housing 11, and the rear side of the rectification grid 16 There are several anti-wear dummy tubes 17 stacked in the height direction, and the two ends of the anti-wear dummy tubes 17 are fixed on the left and right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com