Integrated device and method for removing sulfur oxide and heavy metal in non-ferrous metal smelting and acid-making flue gas

A technology of non-ferrous metals and sulfur oxides, applied in chemical instruments and methods, combined devices, gas treatment, etc., can solve the problems of secondary pollution with dirty acid, complex system, and low efficiency of removing heavy metals, so as to ensure quality and synergy High purification efficiency, no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

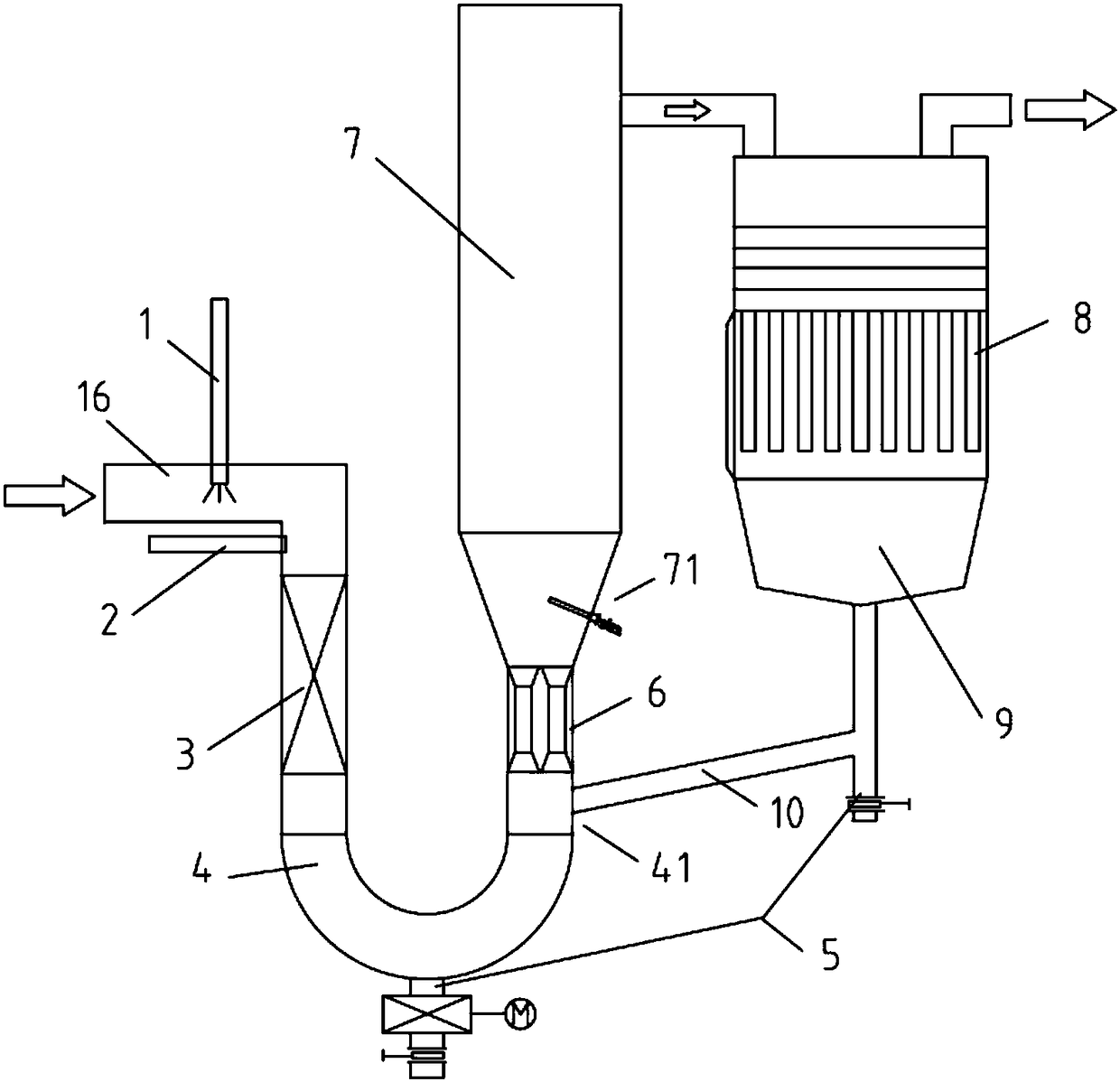

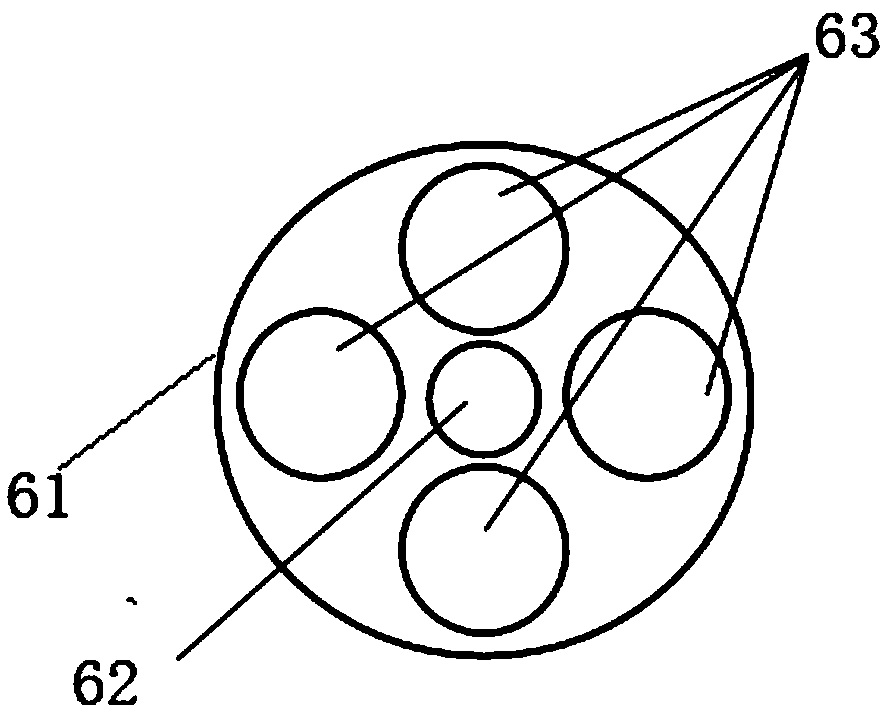

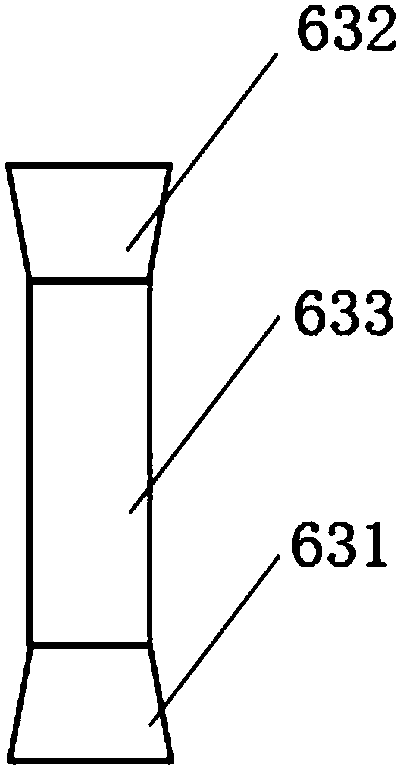

[0030] Such as figure 1 As shown, this embodiment discloses a method for removing SO in the flue gas of acid production in non-ferrous metal smelting. 3 and heavy metal integrated device (integrated device for short), mainly including sequentially connected intake flue 16, heat exchanger 3, U-shaped flue 4, Venturi tube bundle 6, circulating fluidized bed reactor 7 and dust collector 8. The above-mentioned parts can be fixedly connected by mature welding technology to form a cycle-sealed integrated device. The flue gas enters from the intake flue 16, passes through the heat exchanger 3 from top to bottom, enters the U-shaped flue 4, passes through the U-shaped flue 4, enters the Venturi tube bundle 6 from bottom to top, and passes through the Venturi tube bundle 6 After acceleration, it enters the fluidized bed reactor 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com