Volute, fan with same and exhaust hood

A volute and front plate technology, applied in the direction of oil fume removal, machine/engine, mechanical equipment, etc., can solve the problems of uneven flow field distribution of volute, sudden change of flow area, large dynamic noise, etc., to achieve uniform flow, increase Large flow space, the effect of reducing aerodynamic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

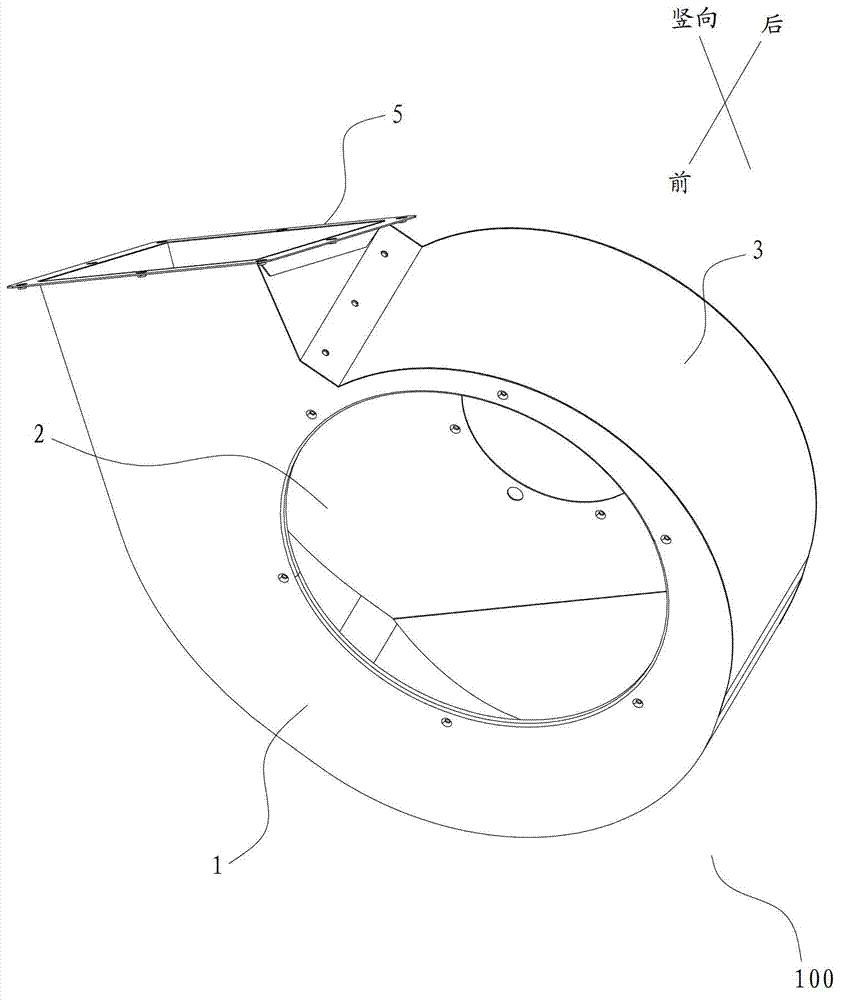

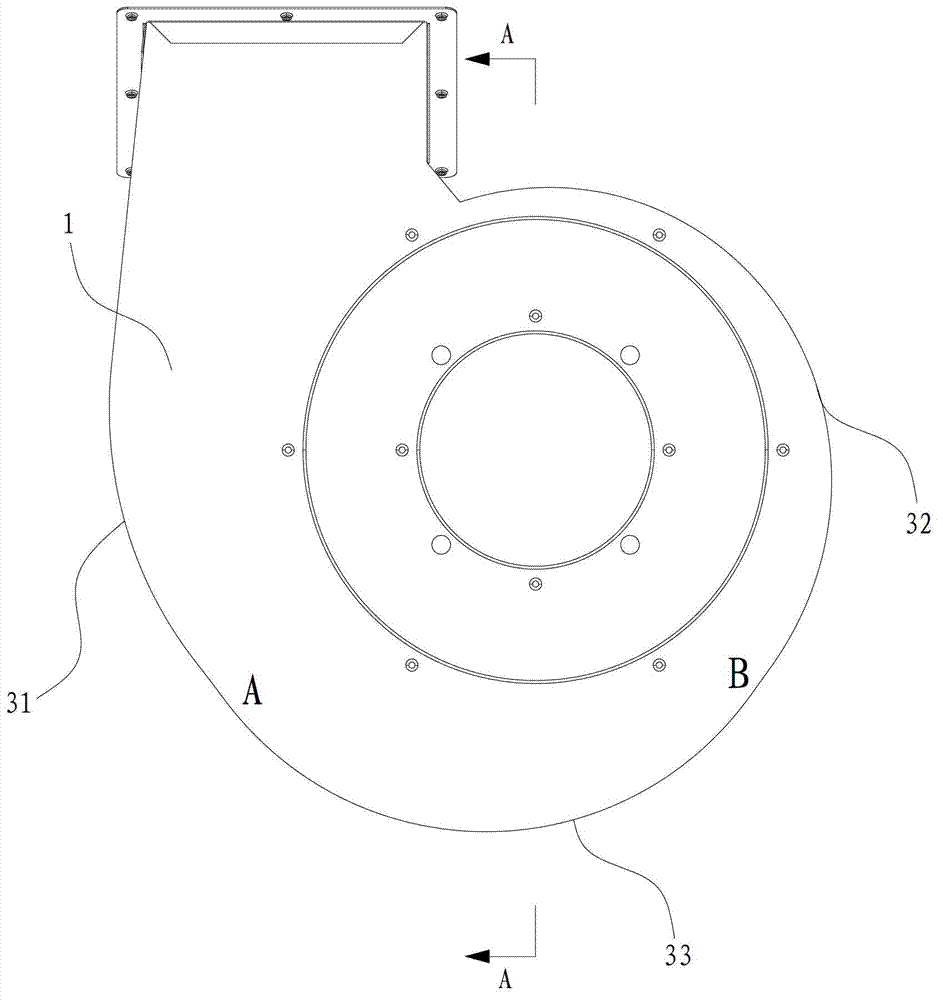

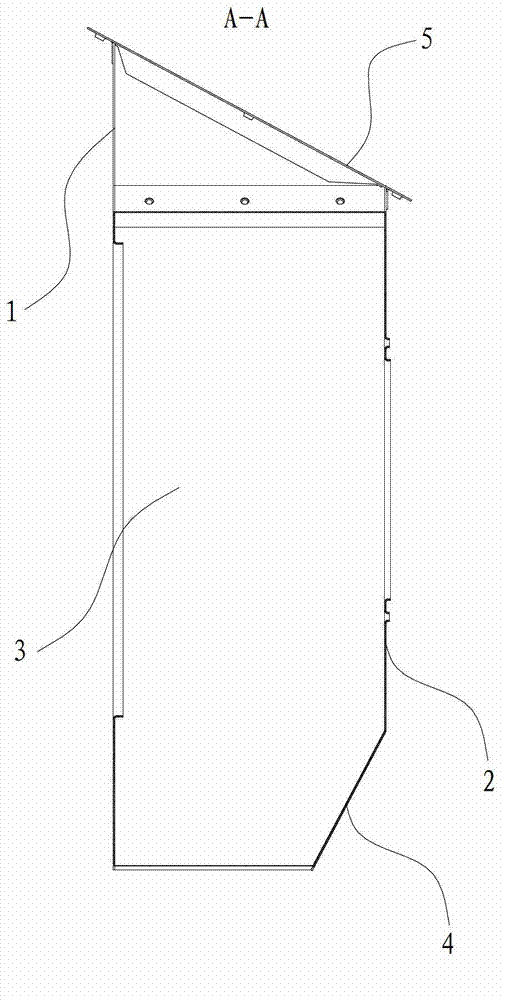

[0064] Refer below Figure 1-Figure 5 A volute 100 according to an embodiment of the first aspect of the present invention is described, and the fan volute 100 is arranged in a range hood.

[0065] like figure 1 As shown, the volute 100 according to the embodiment of the present invention includes: a front plate 1 , a rear plate 2 and a surrounding plate 3 . The front panel 1 and the rear panel 2 can be arranged in parallel in the front-rear direction, and the surrounding panel 3 is connected between the front panel 1 and the rear panel 2, and jointly defines an air duct space for passing the wind. Wherein, there is a volute flange 5 on the top of the front panel 1 , the rear panel 2 and the surrounding panel 3 , through which the fan volute 100 can be fixed in the range hood.

[0066] In an example of the present invention, both sides of the surrounding plate 3 can be respectively connected to the front plate 1 and the rear plate 2 by welding. Of course, the present inven...

Embodiment 2

[0082] like Figure 6-Figure 9 As shown, the same parts of the second embodiment and the first embodiment will not be described in detail here, and only the different parts will be described in detail in this embodiment.

[0083] In this embodiment, an inclined panel 4' is formed on the lower part of the front panel 1', as Image 6 and Figure 7 shown. Preferably, the inclined panel 4' is formed by bending the lower part of the front panel 1' into the volute. In the following description, the inclined panel 4' is formed by bending the lower part of the front plate 1' into the volute as an example for illustration.

[0084] like Figure 8Shown, the projection of the upper edge of the inclined panel 4 ' on the vertical plane parallel to the front plate 1 ' is a straight line AB, that is, the edge of the front plate 1 ' bottom bent in the volute is AB. The projection of the first helicoid section 31' on a vertical plane parallel to the front plate 1' is a first helix. The p...

Embodiment 3

[0093] like Figure 10-Figure 13 As shown, the same parts of the third embodiment and the first embodiment will not be described in detail here, and only the different parts will be described in detail in this embodiment.

[0094] like Figure 10 and Figure 11 As shown, in the third embodiment of the volute of the present invention, the lower parts of the front plate 1 ″ and the rear plate 2 ″ are respectively formed with a first inclined panel 41 ″ and a second inclined panel 42 ″. Preferably, the first inclined panel 41" is formed by bending the lower part of the front plate 1" into the volute, and the second inclined panel 42" is formed by bending the lower part of the rear plate 2" into the volute. In the following description, the first inclined panel 41 ″ and the second inclined panel 42 ″ are formed by bending the lower parts of the front plate 1 ″ and the rear plate 2 ″ into the volute as an example for illustration.

[0095] like Figure 12 As shown, the projecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com