Flue gas denitrating method and flue gas denitrating apparatus with special rectifier cell

A technology of rectifying elements and flue gas, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as high requirements for installation and positioning, complex structure of guide vanes, and complex structure of reactors, etc., and achieve reduction The effect of debugging workload, simple structure and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

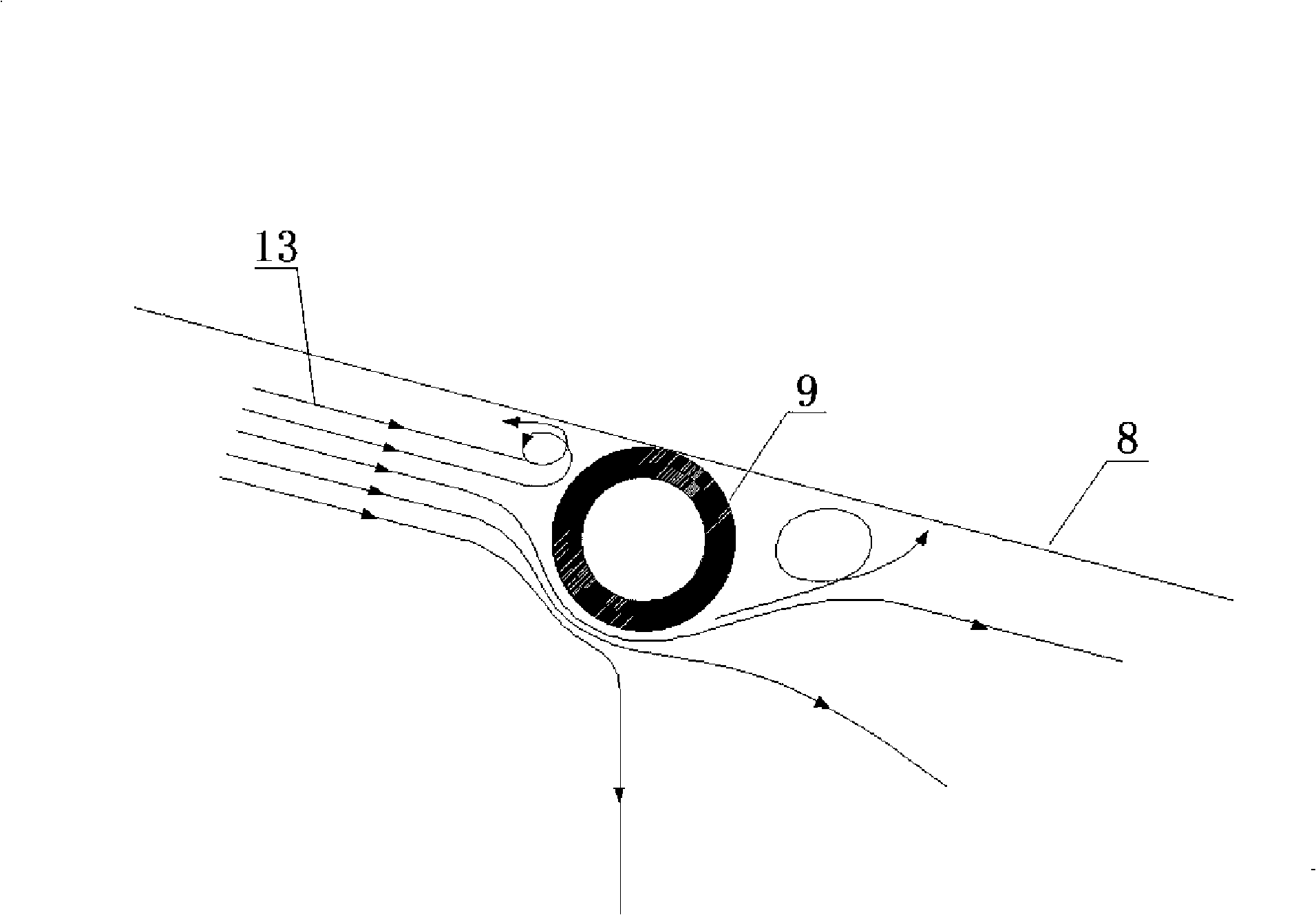

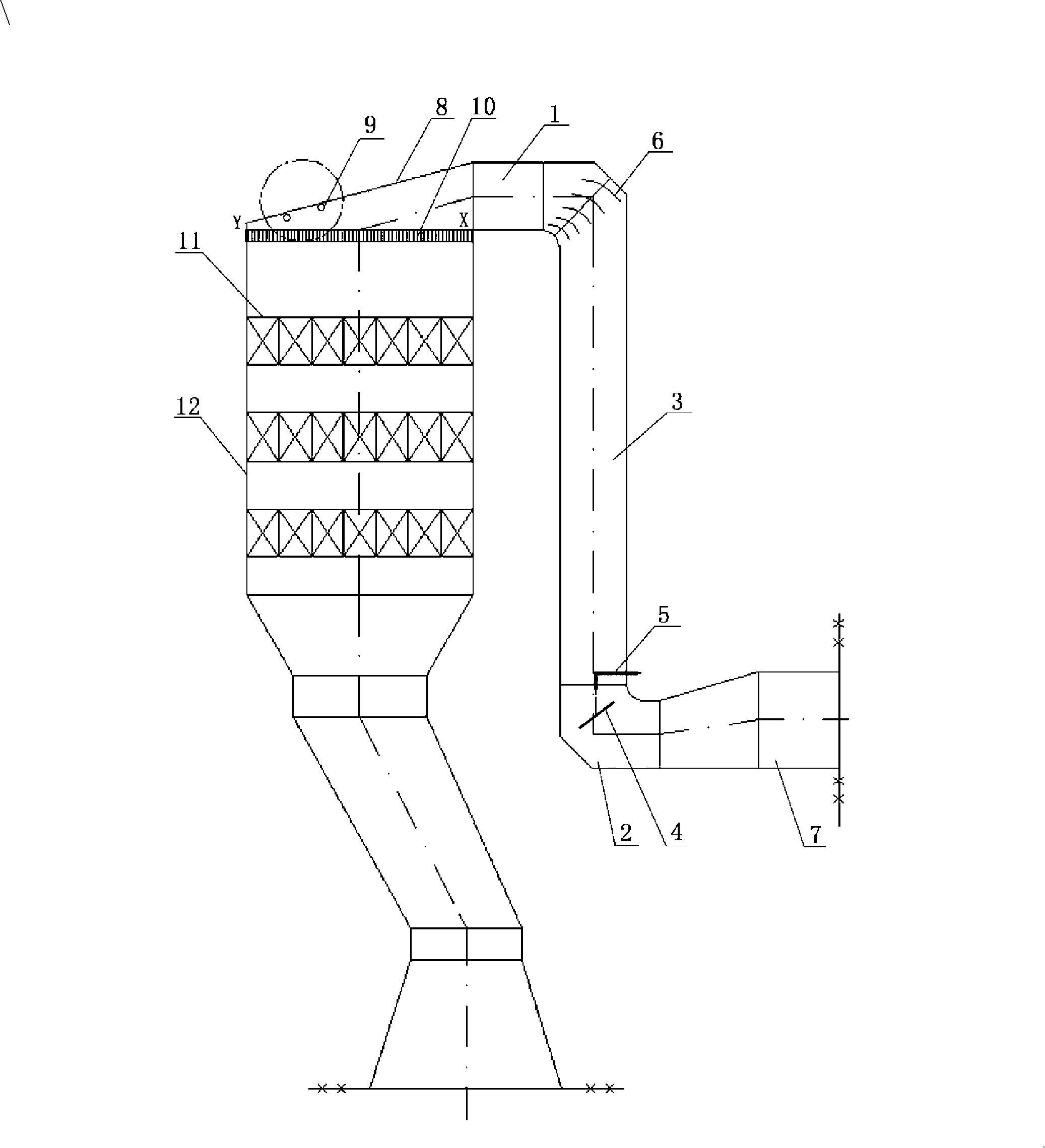

[0031] Example: Under the condition that the flow velocity of the flue in the vertical section of the SCR reactor is 11--15m / s, and the surface flow velocity of the catalyst in the first layer of the SCR reactor is 3.1--5m / s. Two rectifying steel pipes with different diameters, 45mm and 89mm, are arranged on the flue of the tapered section. The net distance between the grid bars of the grid type equal pressure rectifier is 11.25mm, and the height of the grid bars is 37.50mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com