Automobile tail door inner plate forming technology

A forming process and tailgate technology, applied to forming tools, manufacturing tools, vehicle parts, etc., can solve the problems of long manufacturing time, heavy workload, insufficient internal forming, etc., to reduce debugging time, improve work efficiency, reduce The Effect of Small Debugging Efforts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

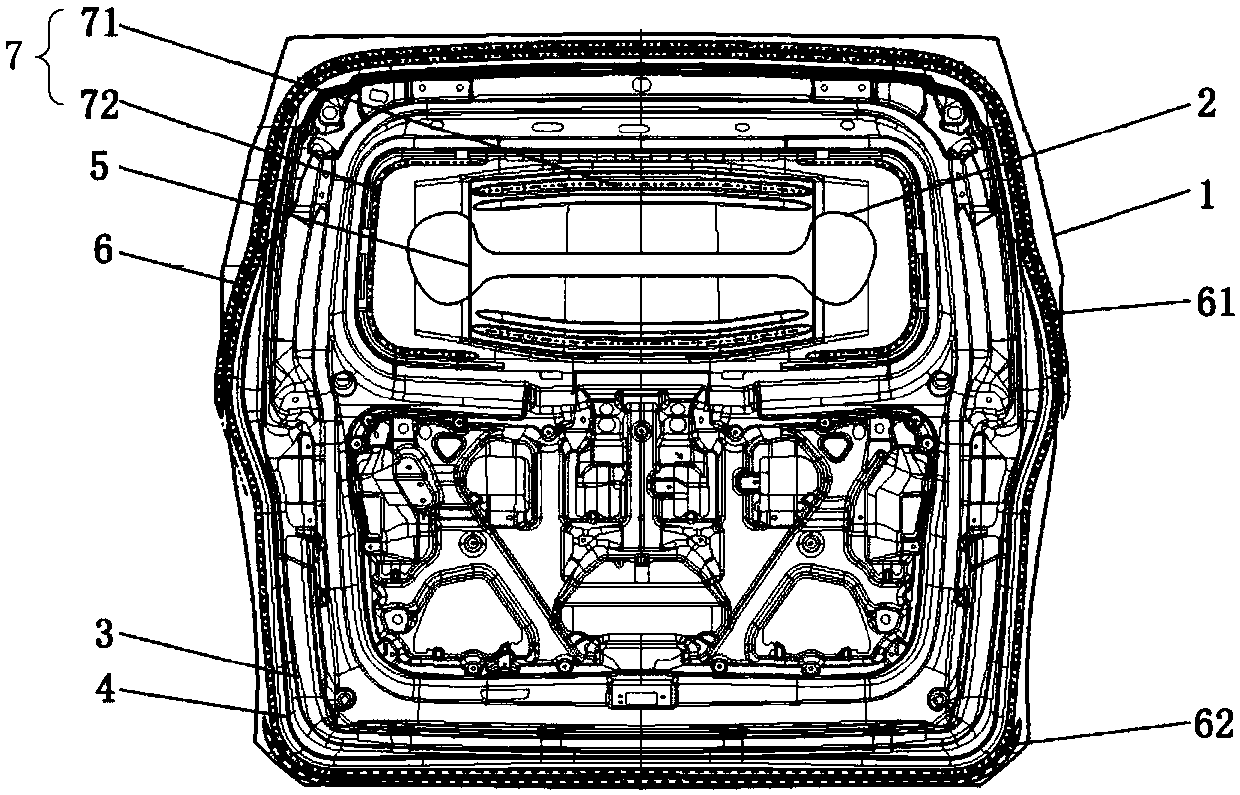

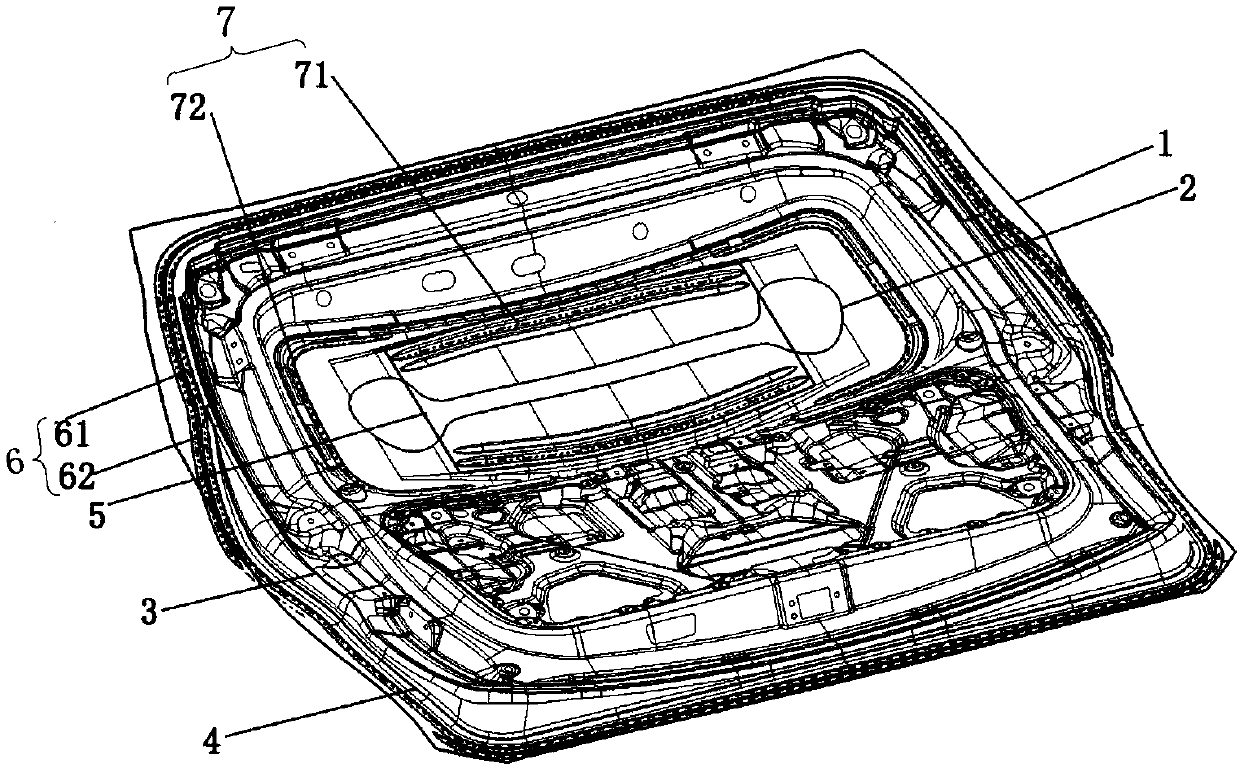

[0026] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

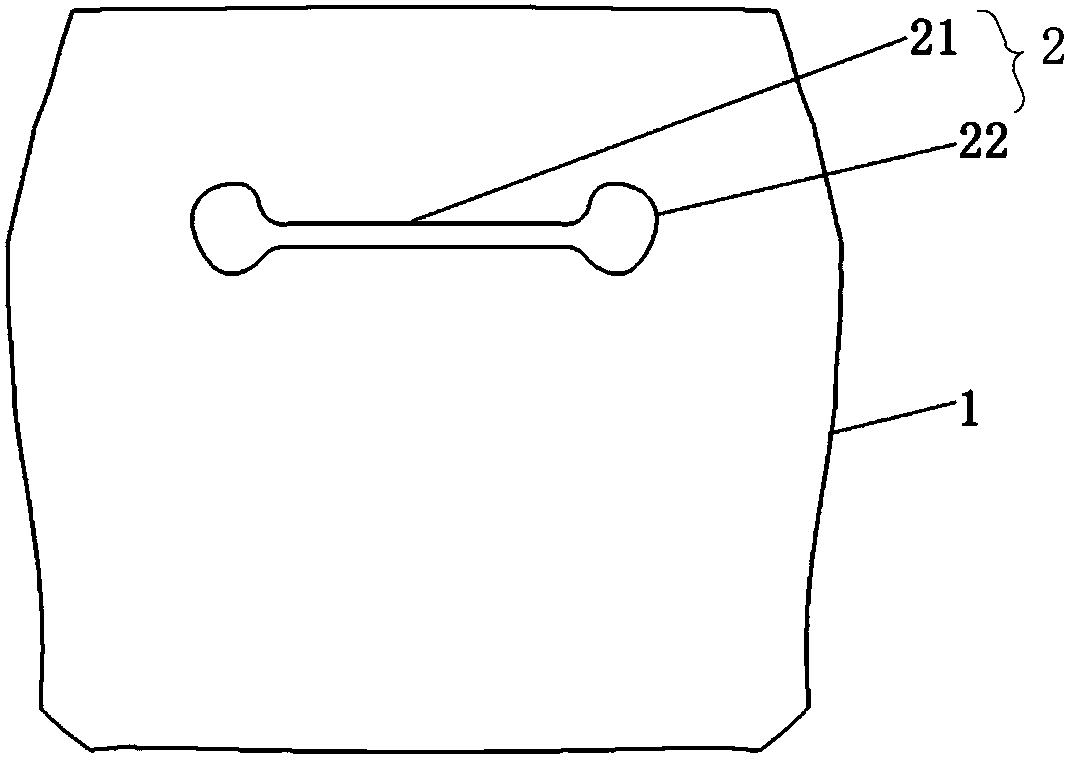

[0027] Embodiments of the present invention: a process for forming the inner panel of the tailgate of an automobile, mainly used for the inner panel of the tailgate whose upper and lower sides are not in the same plane, comprising the following steps:

[0028] Step 1. According to the shape of the inner panel of the tailgate of the automobile, determine that the drawing die surface is V-shaped with the opening facing upward. For the tailgate inner panel whose upper and lower sides are not on the same plane (basically, the tailgate inner panel with a V-shaped longitudinal section), usually the V-shaped opening is formed either upwards or downwards during drawing forming. If the opening is formed facing downward, the V-shaped corner is at the top, and the top blank flows faster during drawing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com