Flue gas system for ultra-clean treatment of cement kiln exhaust gas

A cement kiln and tail gas technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of strict emission limit, lower emission concentration, low denitration efficiency, etc., to increase the contact area, improve the utilization rate, System reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

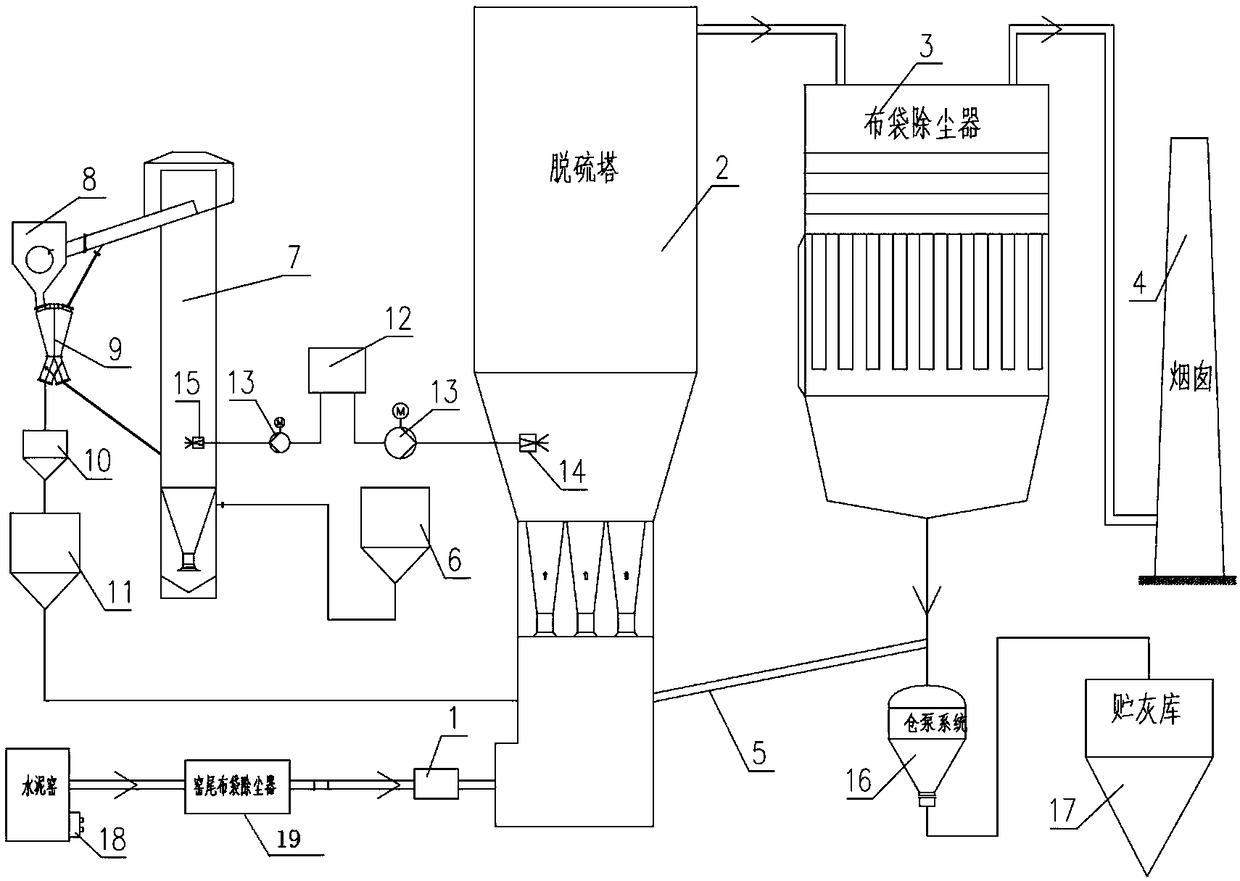

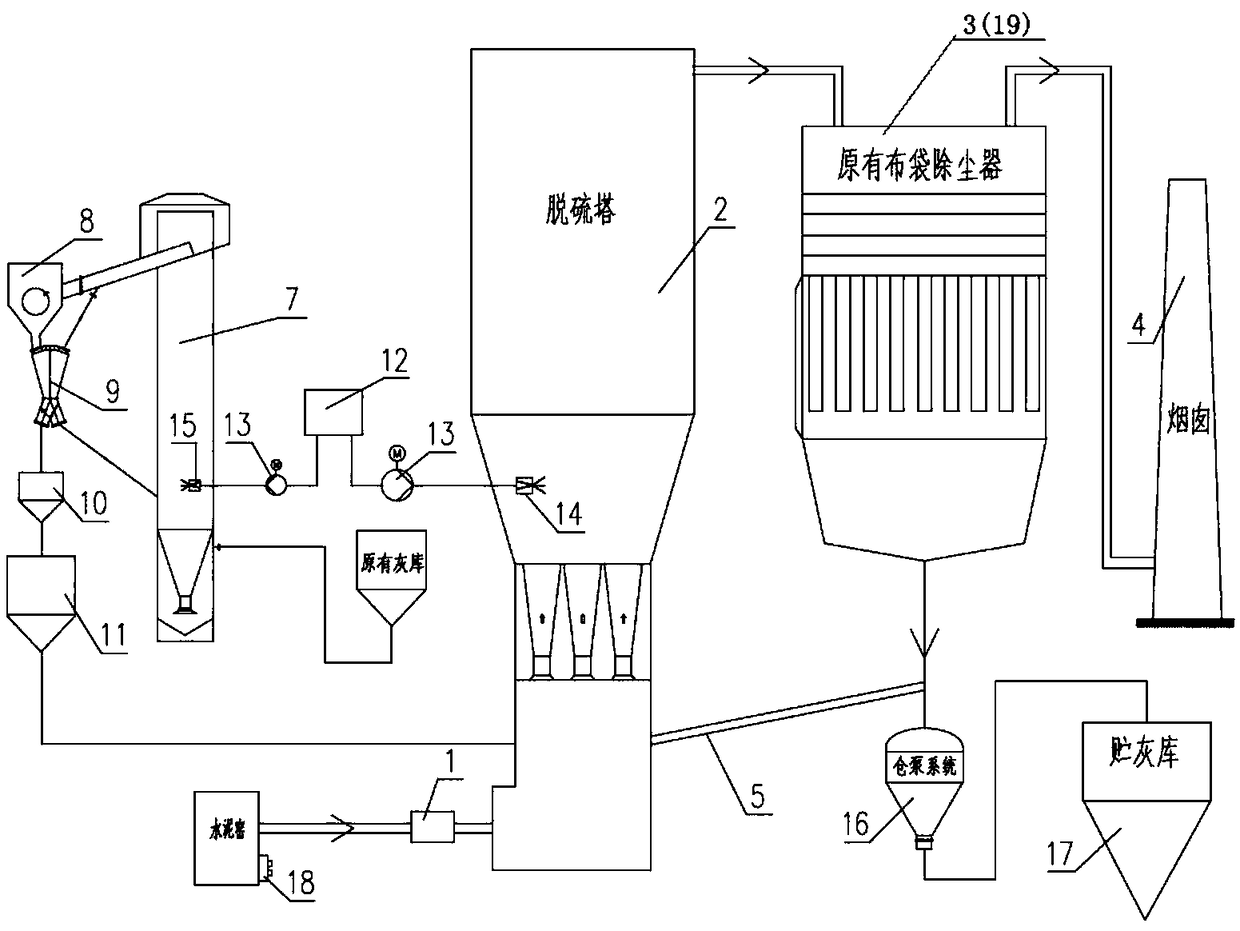

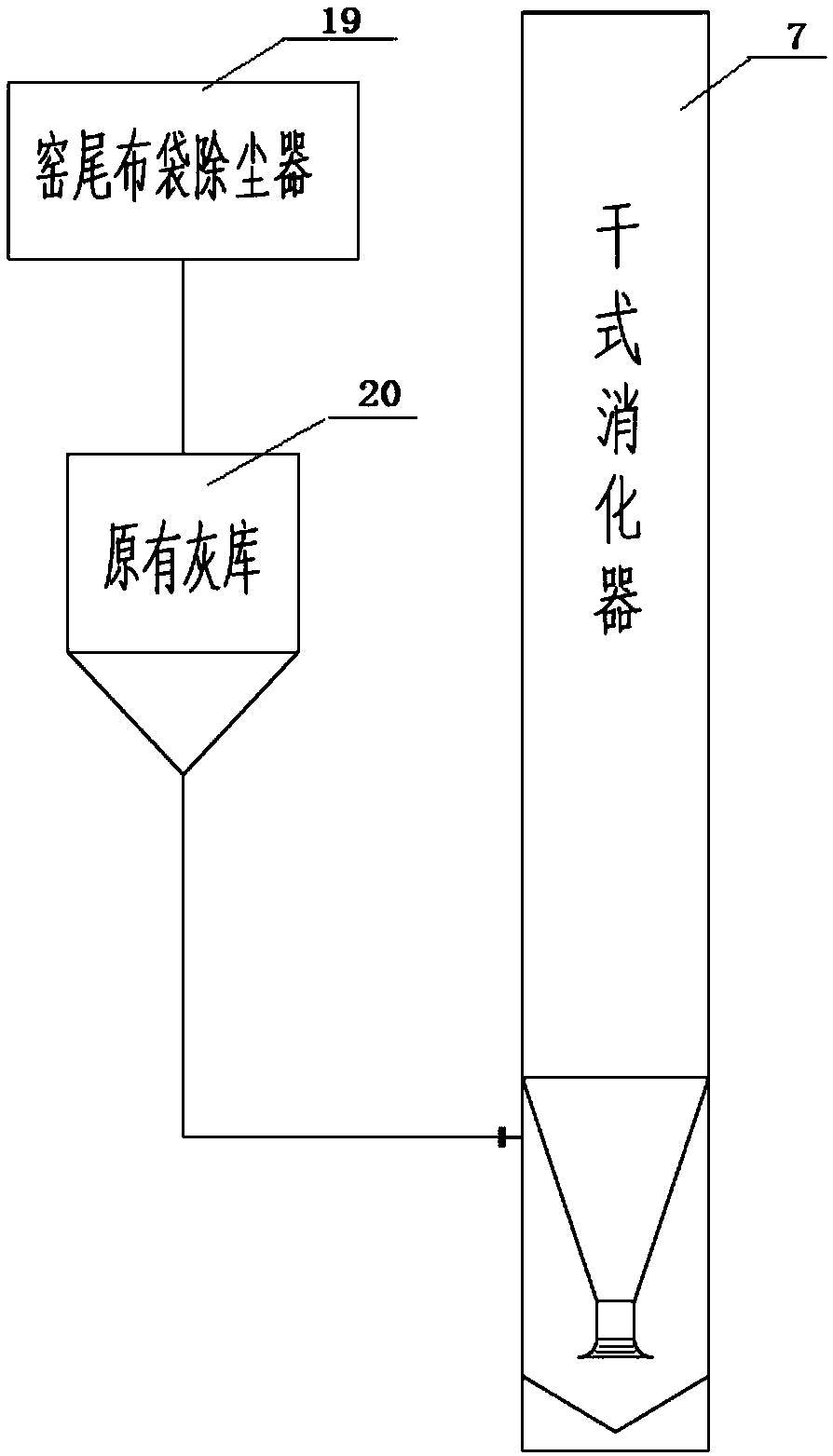

[0032] The preferred embodiments of the present invention will now be further described in conjunction with the accompanying drawings. It should be understood that the accompanying drawings are simplified schematic diagrams illustrating the basic structure of the patent in a schematic manner, so it only shows the composition related to the patent of the present invention.

[0033] Such as figure 1 As shown in the embodiment, a flue gas system for ultra-clean treatment of cement kiln tail gas is disclosed, including oxidation and denitrification reactor 1, CFB absorption tower 2, bag filter 3, chimney 4, process water system, absorbent preparation and Supply system, and desulfurization ash circulation and conveying system. The inlet of the oxidation denitrification reactor 1 is connected to the outlet of the kiln tail bag filter 19 (that is, the original bag filter installed at the outlet of the cement kiln), and the outlet of the oxidation denitrification reactor 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com