Polystyrene sulfonic acid resin catalyst as well as preparation method and application of polystyrene sulfonic acid resin catalyst

A polystyrene sulfonic acid and catalyst technology, applied in catalyst activation/preparation, catalyst, catalytic reaction and other directions, can solve the problems of low raw material concentration, thermal deactivation of catalyst, insufficient thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

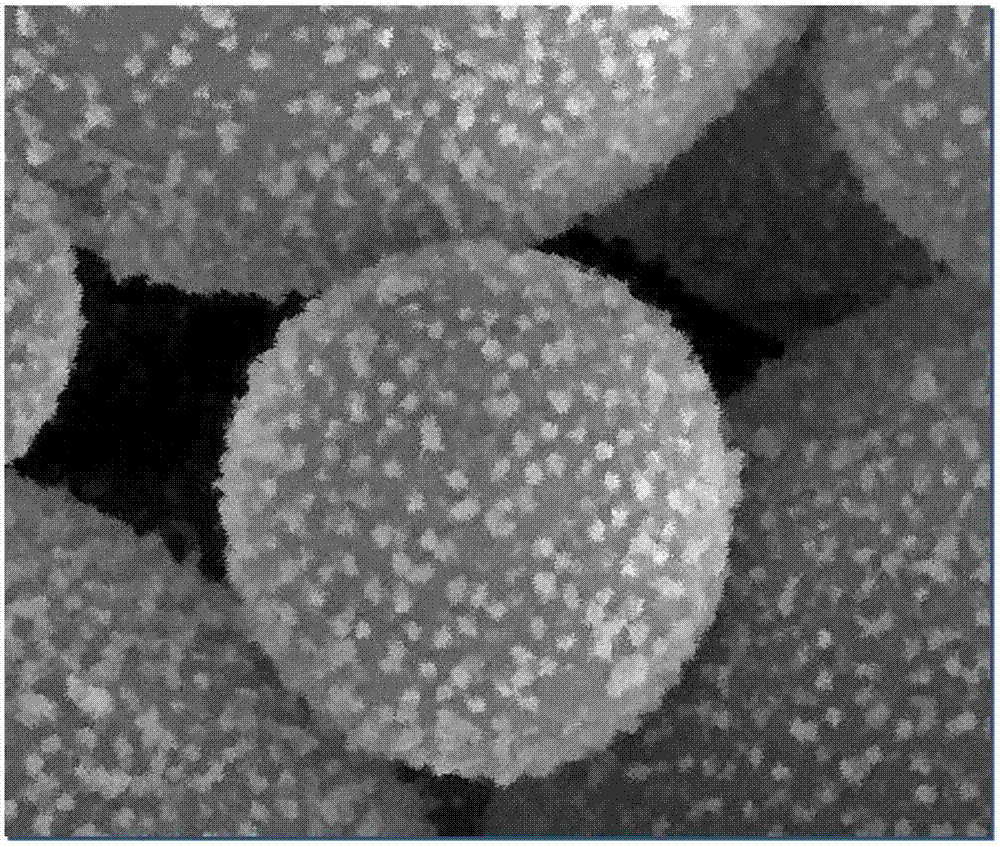

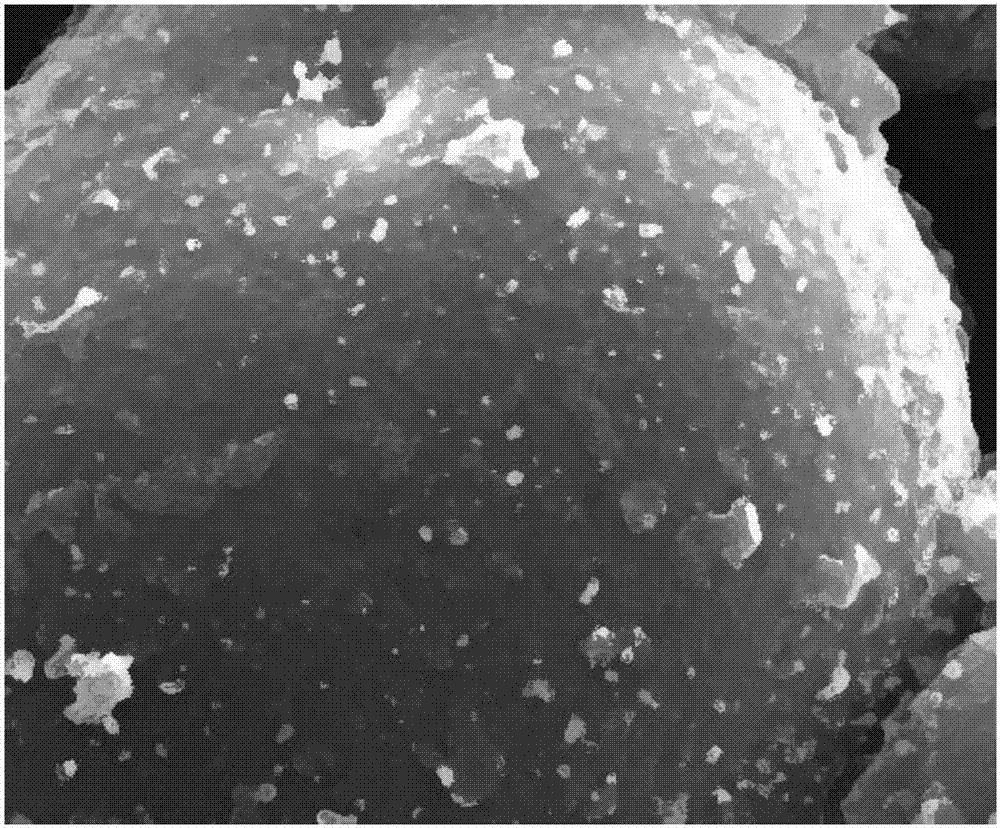

[0104] Preparation of Catalyst 1:

[0105] (1) Add 323L of derusted nickel foam into the 1 cubic meter stirred tank after nitrogen replacement, the minimum dimension of the foam nickel is 0.1mm, and the maximum dimension is 0.3mm. Then, 350L of pentaerythritol monooleate was added into the stirred tank, and stirred at room temperature for 2 hours under the protection of nitrogen. Then, under the protection of nitrogen, the liquid in the reaction kettle is leached out through the lower outlet with a filter screen, and the pentaerythritol monooleate on the surface of the foamed nickel powder is dried under a nitrogen atmosphere for subsequent use.

[0106] (2) Add the aqueous solution (1.5wt%) of the polyvinyl alcohol of 1920kg, the isopropanol of 288kg, the divinylbenzene (density 0.93kg / L) of 23kg, 68kg The styrene (density 0.90kg / L), the dibenzoyl peroxide (density 1.33kg / L) of 1.8kg and the 50L nickel foam that (1) step handles well. Under reflux condensation, raise the re...

Embodiment 2-4

[0111] Preparation of Catalysts 2-4

[0112] Except changing the ratio of nickel foam and polymer monomer (styrene and divinylbenzene), all adopt the same method as that prepared in Example 1, the nickel foam charging capacity is 50L, respectively obtains catalyst 2-4, sees for details Table 1.

[0113] Table 1 Catalysts 2-4

[0114]

Embodiment 5-7

[0116] Preparation of Catalyst 5:

[0117] Except for improving according to the following conditions, other methods in the preparation of catalyst 5 are the same as in Example 1: changing the metal to 50L minimum dimension size is 10 μm, fiber cobalt with maximum dimension size 30 μm, dibenzoyl peroxide, divinylbenzene and The volume ratio of the total volume of styrene to metal is 10:1, the mass ratio of divinylbenzene to styrene is 1:10, the ratio of benzoyl peroxide to the total mass of polymerized monomers is 1:100, isopropanol The mass ratio of the polyvinyl alcohol to the polyvinyl alcohol aqueous solution (1.5wt%) is 10:1, and the mass ratio of the total mass of polymerized monomers to the polyvinyl alcohol aqueous solution is 1:30. In the obtained catalyst 5, the metal covered by polystyrene sulfonic acid resin accounts for 50% of the total volume of the metal, and the uncoated metal accounts for 50% of the total volume of the metal. The average particle diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com