Thermal expansion valve having diversion function

A thermal expansion valve and function technology, applied in the field of thermal expansion valve, can solve the problems of uneven distribution of working medium by a distributor, easy to generate vibration and noise, and adverse air conditioning system operation, etc., and achieves small flow resistance, reduced vibration, practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

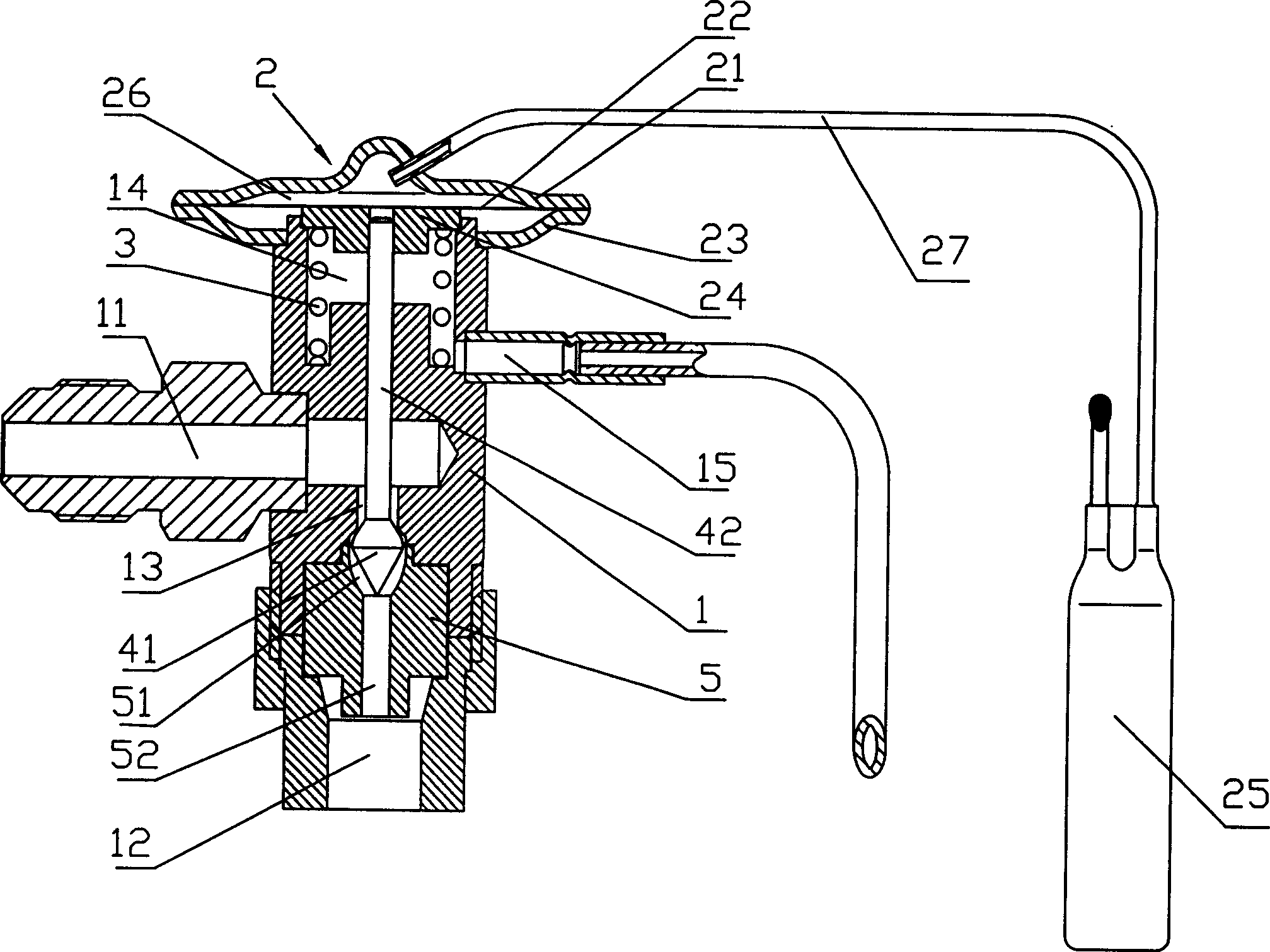

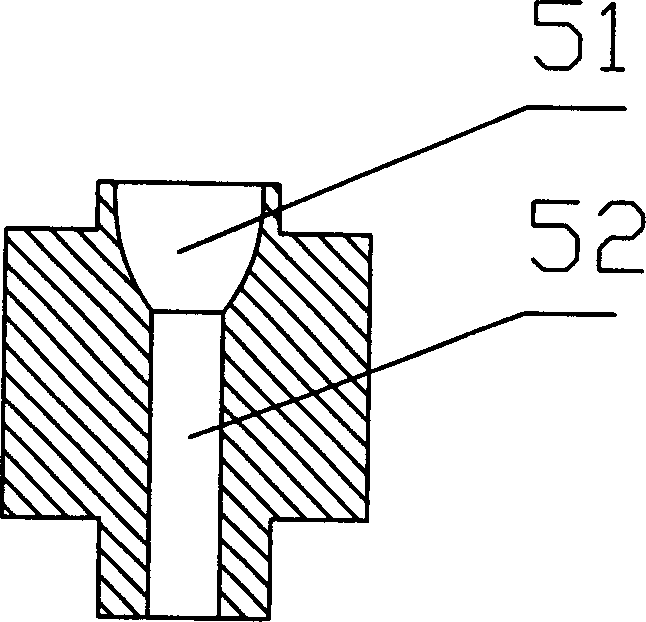

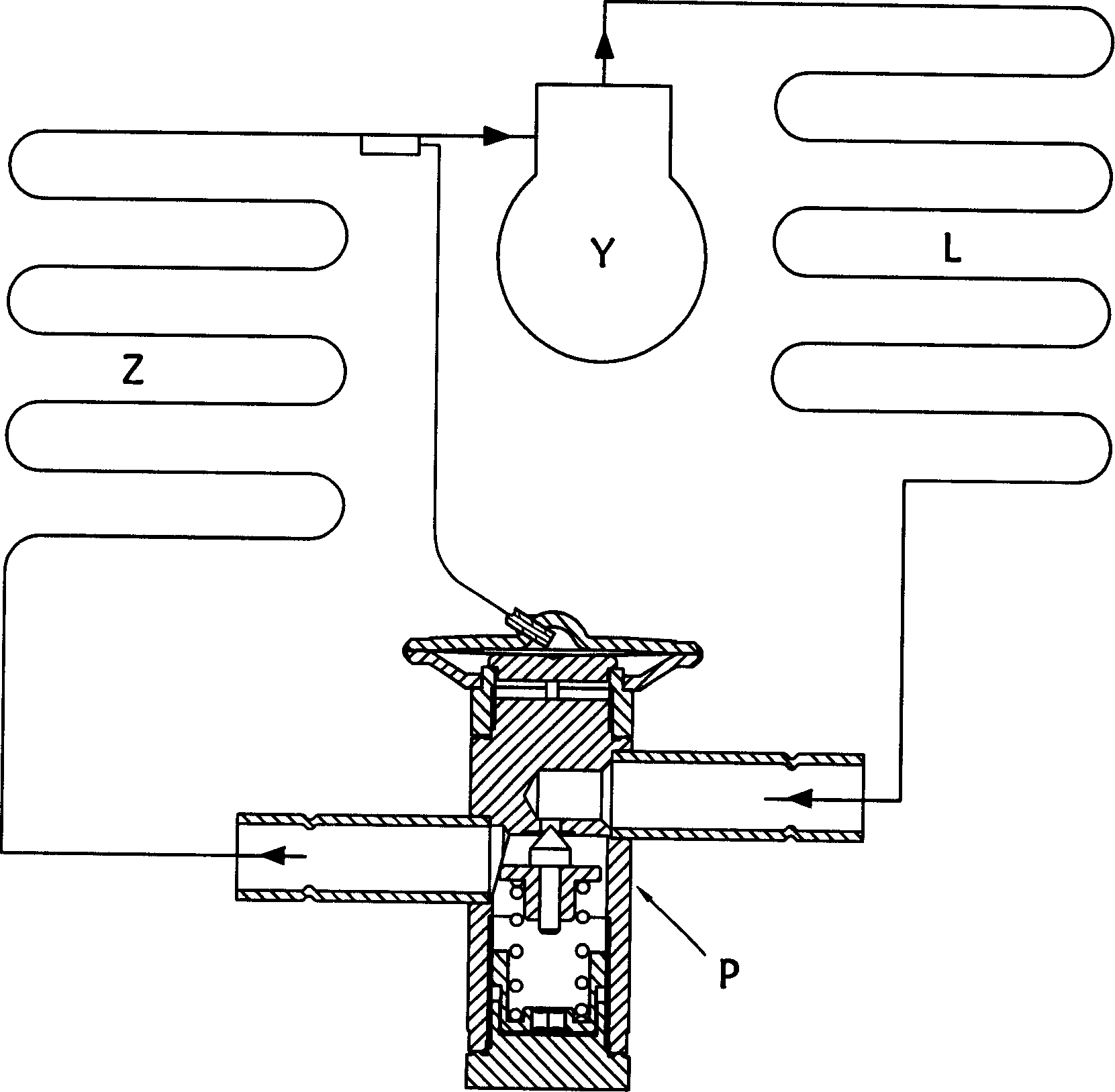

[0022] Such as figure 1 The thermal expansion valve shown includes a valve body 1, an air box head part 2, a valve core part and an adjustment spring 3. The valve body 1 has an inlet 11, an outlet 12 and a valve port 13 connecting the inlet and the outlet, and its upper end Open the accommodation cavity 14 for setting the adjustment spring, connect the external balance connecting pipe 15 from the accommodation cavity, and fix a flow guide element 5 at the lower end of the valve port 13, and open a flow guide channel connecting the valve port and the outlet on the flow guide element , a section of the diversion channel close to the valve port is an arc-shaped expansion part 51, and a section away from the valve port is an equal-diameter hole 52; And the temperature-sensing package 25, the air box seat 23 is fixed on the upper end of the valve body 1, the air box cover 21 and the diaphragm 22 form a sealed cavity 26, the temperature-sensing package 25 communicates with the seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com