Simulation platform and test method for flow field arrangement structure of flue gas denitration apparatus

A technology of flow field distribution and simulation platform, applied in teaching models, educational appliances, instruments, etc., can solve the problems of ash blocking, economic loss, reducing denitration efficiency, etc., and achieve a low impact, small pressure loss and uniform flow field distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

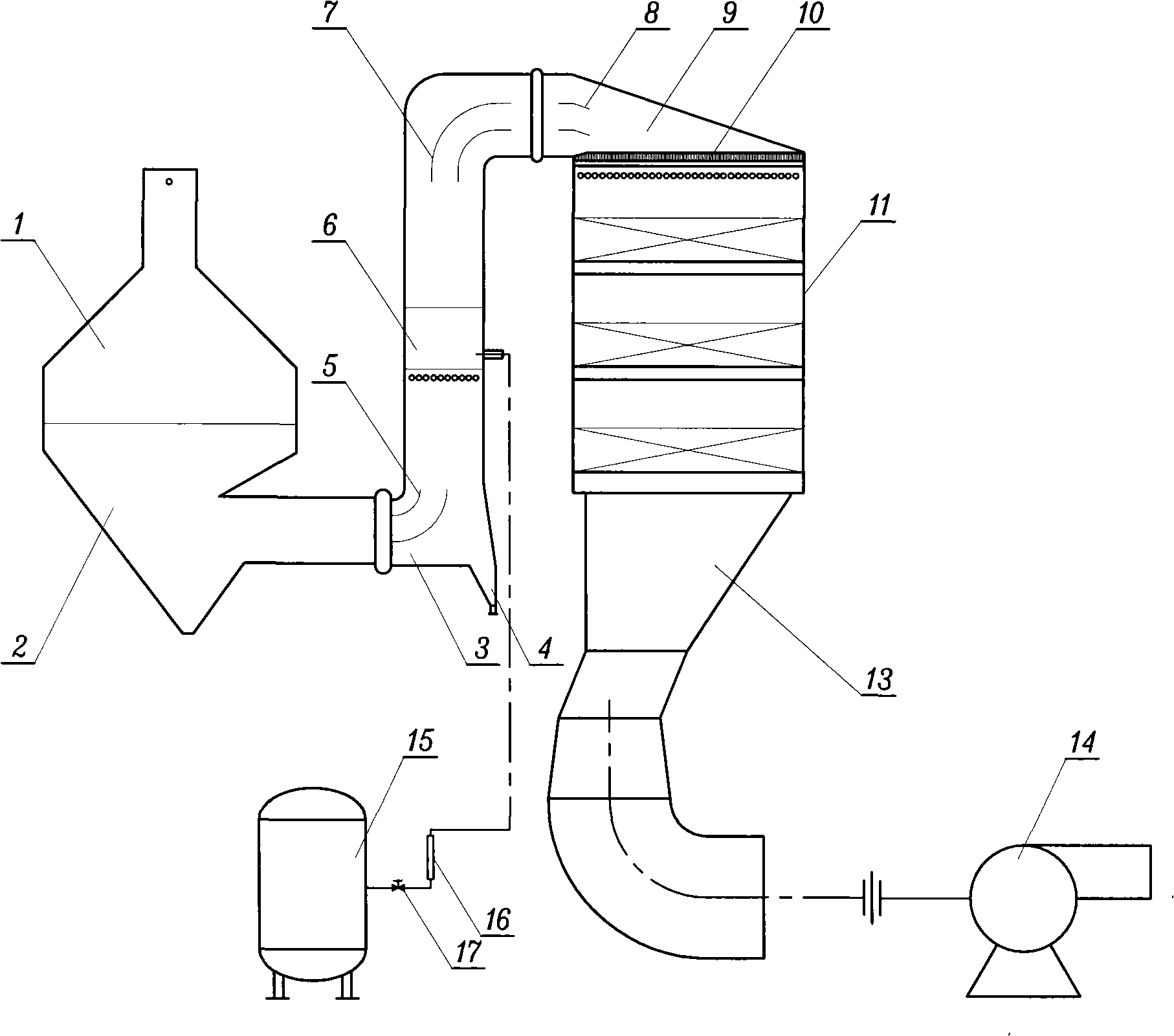

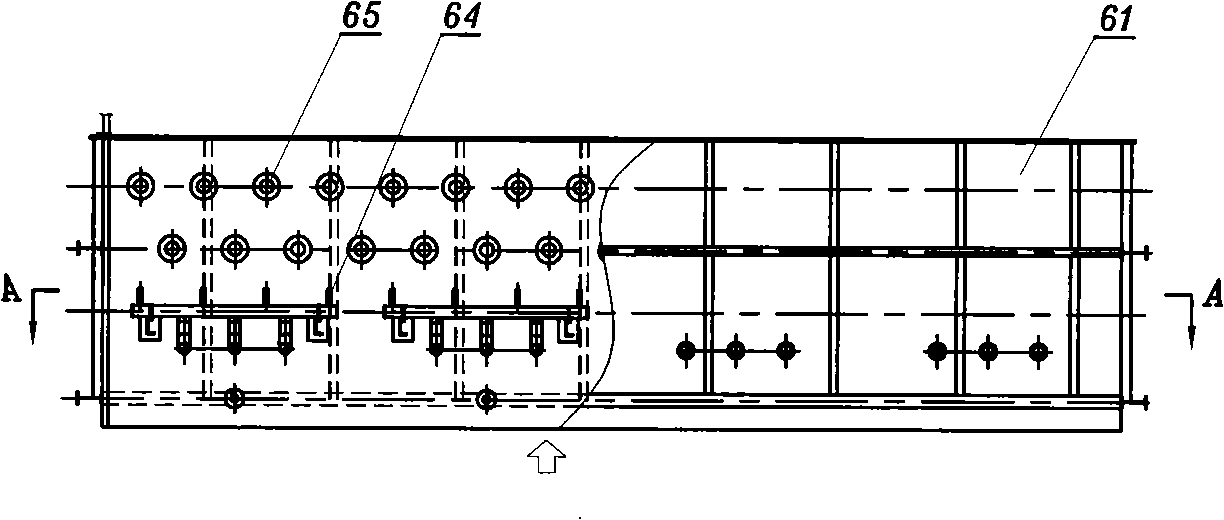

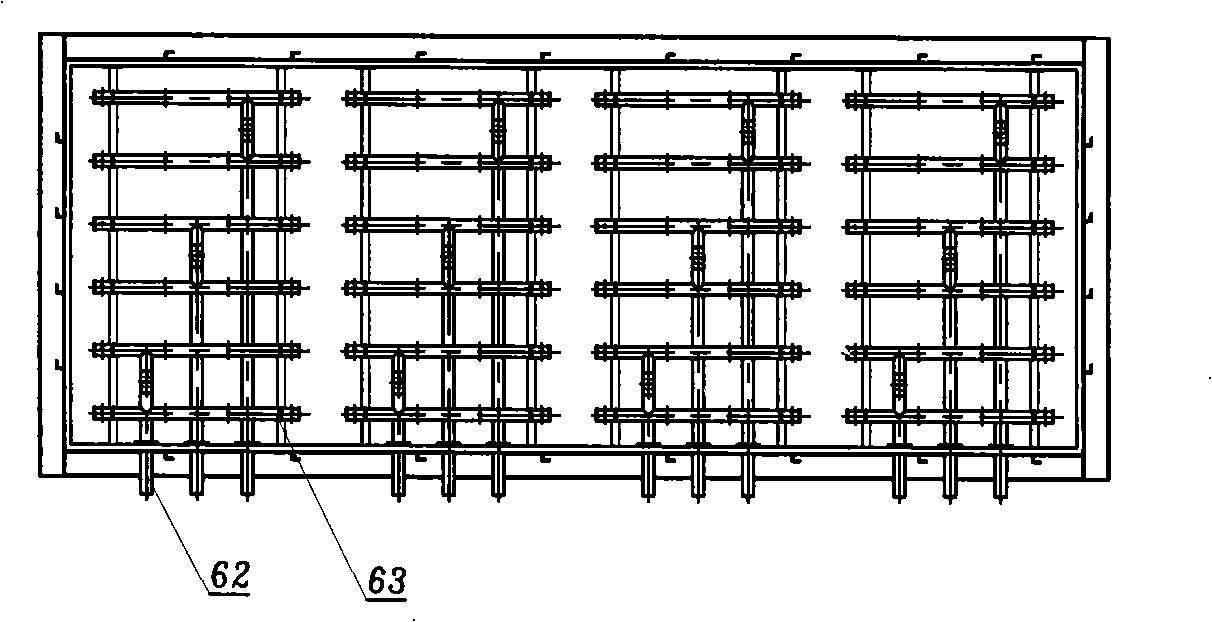

[0032] Such as Figure 1-3 As shown, the simulation platform of the flow field distribution structure of the denitrification device consists of an inlet pipe 1, an economizer 2, an inlet flue 3, an ash hopper 4, a gas injection device 6, a top flue 9, a flow equalizer 10, a reactor 11, Outlet flue 13, blower fan 14 are made up; Described gas injection device is made up of carbon monoxide gas distribution tank 15, shut-off valve 17, flowmeter 16, gas injection device housing 61, injection main pipe 62 that is installed on the housing 61, injection branch pipe 63, nozzle 64 and mixing tube 65 form. The outlet of the carbon monoxide gas distribution tank 15 is connected with the inlet of the injection main pipe 62 through a pipeline, and a shut-off valve 17 and a flow meter 16 are connected in series in the pipeline. The mixing pipe 65 is installed at the outlet of the nozzle 64, the outlet of the inlet pipe 1 is connected to the inlet of the economizer 2, the outlet of the econ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com