An experimental device for real-time monitoring of the support force distribution of vascular stents in a flow field environment

A real-time monitoring and vascular stent technology, which is applied in the field of mechanical performance testing of medical devices, can solve the problems of many uncertain factors and low precision, and achieve the effect of controllable flow and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

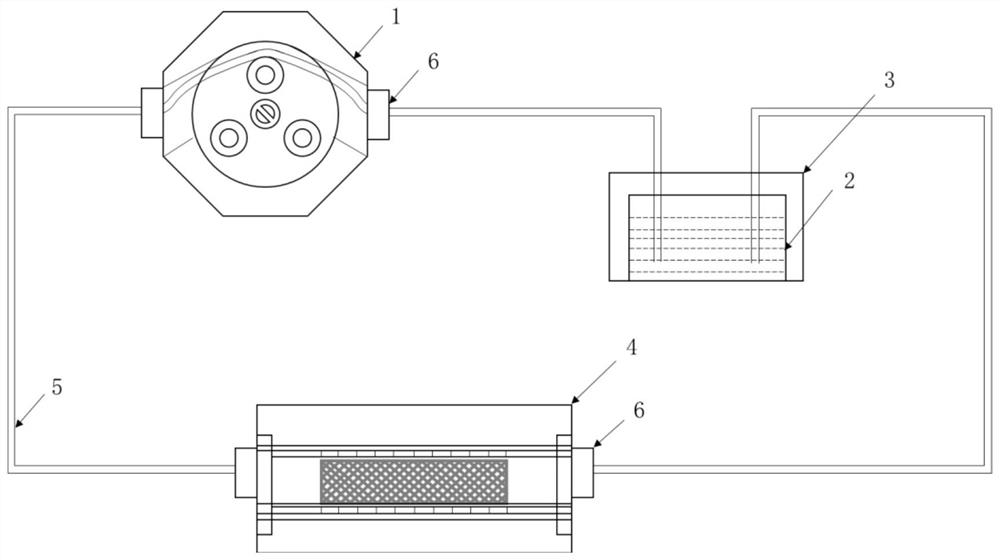

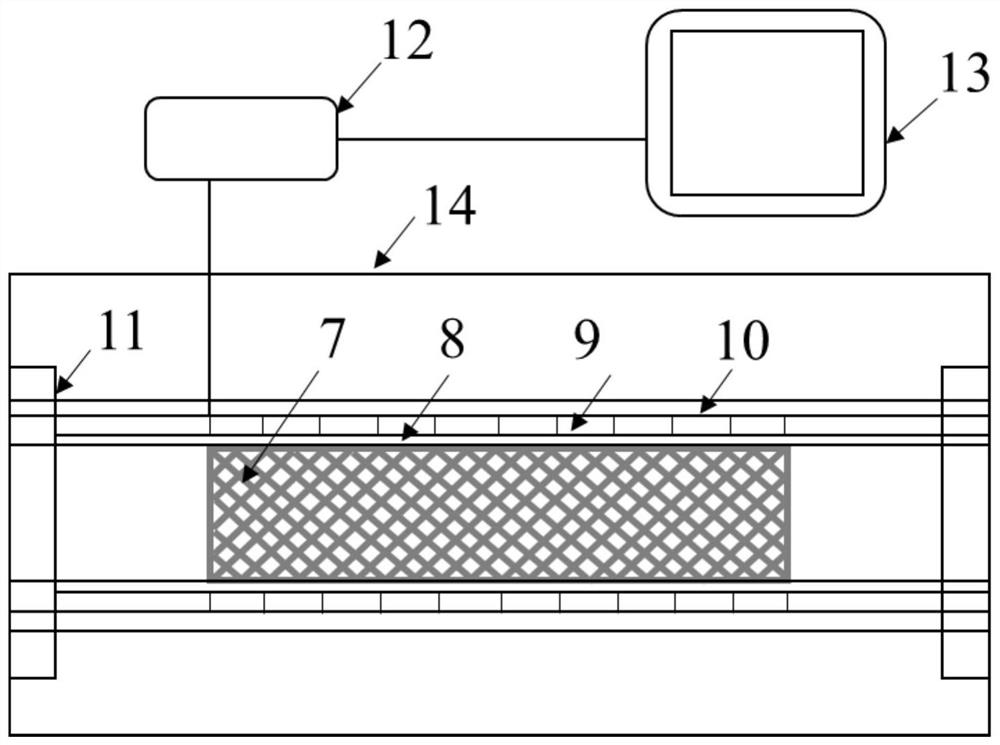

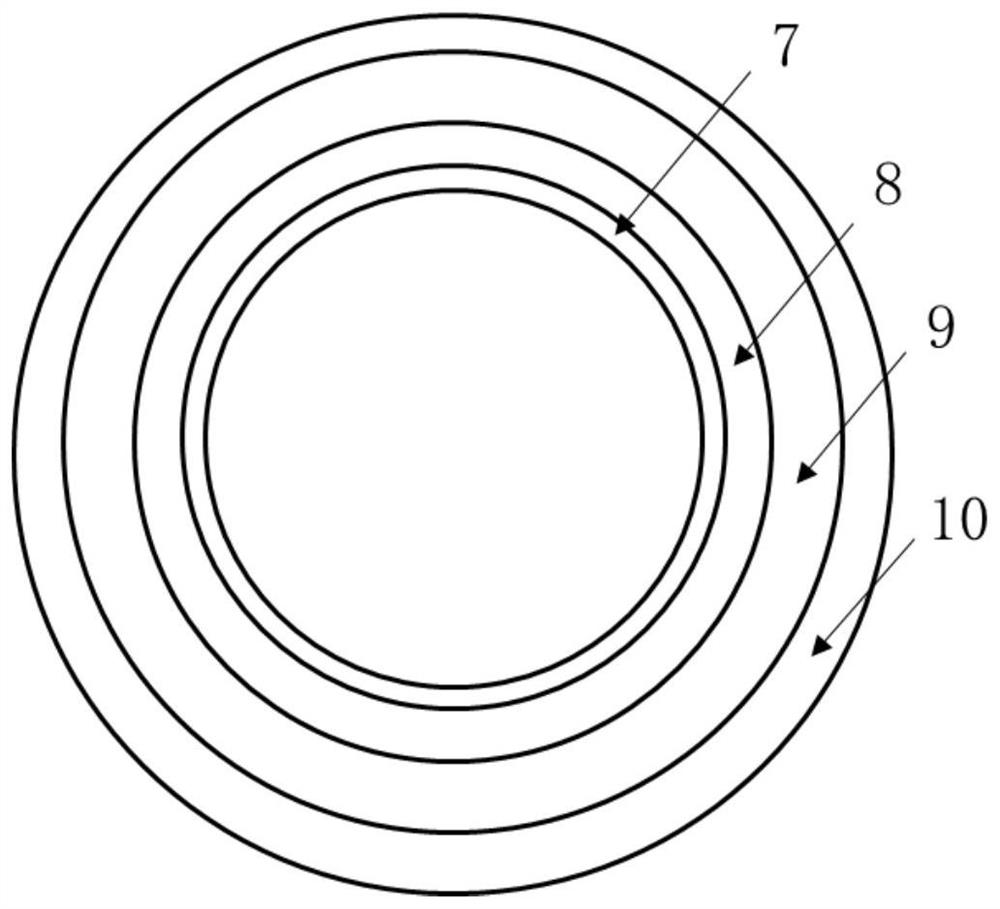

[0039] Such as figure 2 As shown in the device, the selected test piece is a braided WE43 magnesium alloy balloon-expandable vascular stent 7. The stent is preloaded on the balloon catheter and delivered to the polyurethane PU transparent elastic tube 8, and the balloon is filled with the inflation pressure pump. When the balloon reaches the nominal pressure, the stent squeezes the polyurethane PU transparent elastic tube 8 outward, and at the same time the stent expands, and the balloon at the distal end of the catheter is withdrawn after decompression and contraction. The corrosive medium used is a simulated plasma solution at a temperature of 37°C , the velocity of the flow field is controlled by the speed-adjustable peristaltic pump 1. In the corrosive medium fluid, the radial support force of the magnesium alloy balloon-expandable vascular stent 7 decreases continuously with its own degradation, and the radial support of each part of the stent can be recorded in real time...

Embodiment 2

[0041] The device used is the same as that in Example 1, and the sample selected is a laser-engraved nickel-titanium alloy self-expanding vascular stent 7. The stent is preloaded on the delivery catheter and placed on the expanded polytetrafluoroethylene ePTFE elastic tube 8 In it, it is connected to the simulated blood circulation device through a silicone hose 5, the corrosive medium used is a simulated plasma solution, the velocity of the flow field is controlled by an adjustable-speed peristaltic pump 1, and the temperature is adjusted to 37°C until the transition temperature of the alloy is reached, and the bracket gradually Deformation expands and produces support force on the elastic tube, real-time recording of radial support force changes in the process of stent expansion and retraction, and research on the influence of blood flow on the radial support force of vascular stents.

Embodiment 3

[0043] The device used is based on the implementation of Case 1 or 2. A local annular plaque is added between the vascular stent and the simulated blood vessel wall. The selected test piece is a drug-eluting AZ31 magnesium alloy balloon-expandable vascular stent formed by laser engraving. 7. The surface has been treated with micro-arc oxidation. The material and size of the annular plaque can be adjusted, which can simulate different degrees of blockage and plaque hardening of the lesion. The stent is preloaded on the balloon catheter and delivered to the polyester transparent elastic tube In 8, the balloon is filled to the nominal pressure by using the filling pressure pump, the stent squeezes the polyester transparent elastic tube 8 outward, and at the same time the stent expands, and the balloon at the distal end of the catheter is withdrawn after decompression and contraction, and the corrosive medium used is simulated Plasma solution, the temperature is 37°C, the speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com