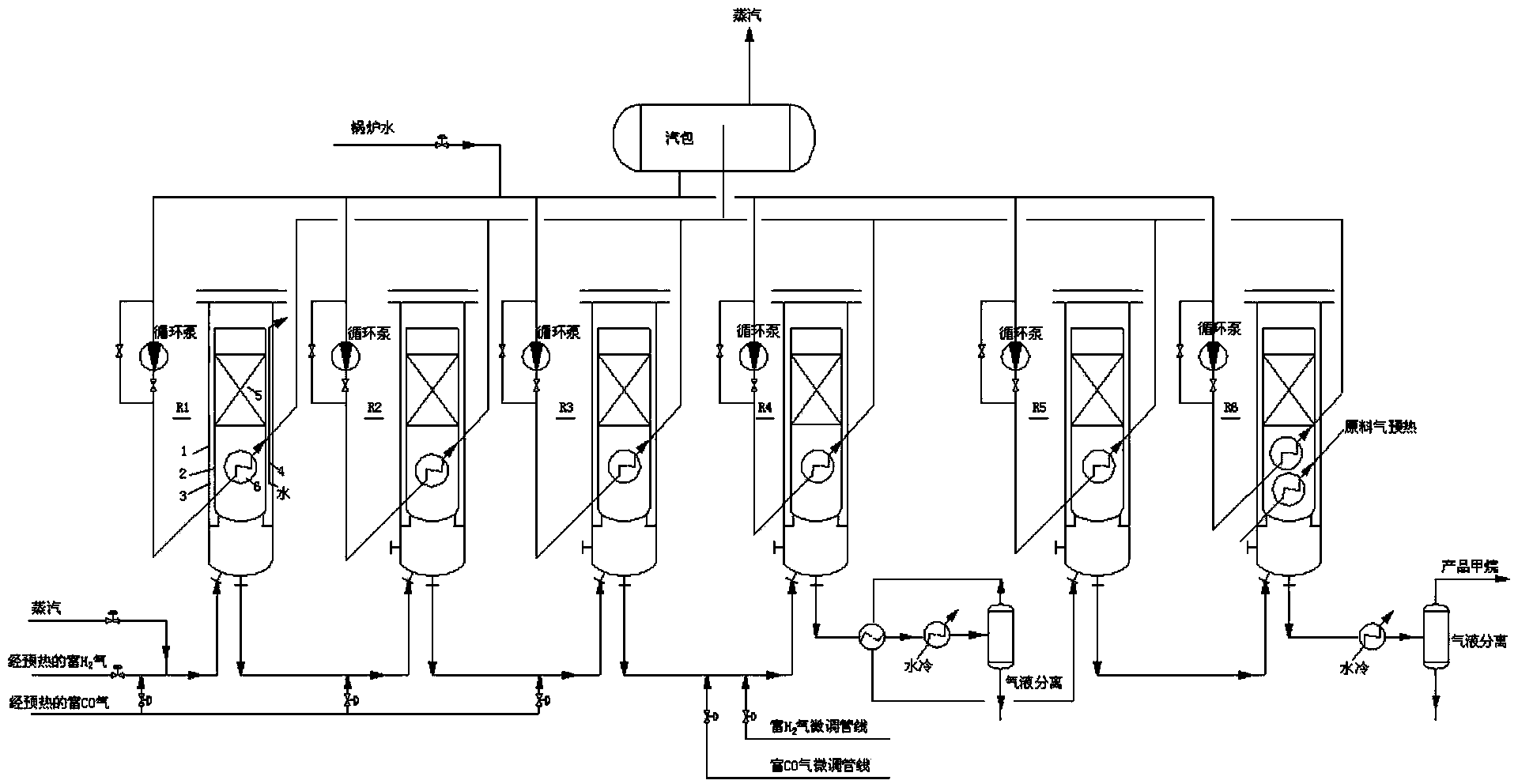

Circulation-free methanation system

A methanation, non-circulating technology, applied in the field of methanation reaction, can solve the problems of high investment, increased feed flow rate of the reactor, unfavorable installation and disassembly, etc., and achieves simplified process system, stable reaction operation, operating cost and construction cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Specifically, if the non-cycle methanation system in this embodiment is used to produce methane, the detailed process is as follows:

[0041] Process gas flow:

[0042] Raw material rich H 2 The gas is mixed with a small amount of CO-rich gas and an appropriate amount of steam, enters the first-stage reactor R1 from the bottom, and flows upward along the gap gas flow channel to the upper part of the reactor inner cylinder. In the interstitial air flow channel, the synthesis gas exchanges heat with the inner tube of the reactor and the water-cooled tube, so that the synthesis gas can enter the catalyst bed from the top or side wall of the inner tube of the reactor at a relatively constant temperature. Catalytic reaction occurs. After the reaction, the product gas at about 700°C (less than 800°C) enters the heat exchange section of the lower part of the reactor. After heat exchange with boiler water, the temperature of the generated gas drops to about 270°C (at least above 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com