Preparation method of silicon carbide asymmetric composite filter tube membrane with controllable aperture, and device

A composite filtration and silicon carbide technology, applied in chemical instruments and methods, membrane technology, ceramic products, etc., can solve problems such as low porosity, large fluctuations, and restrictions on the application and development of porous silicon carbide ceramics, and achieve long service life , The resistance drop is small, the effect of good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

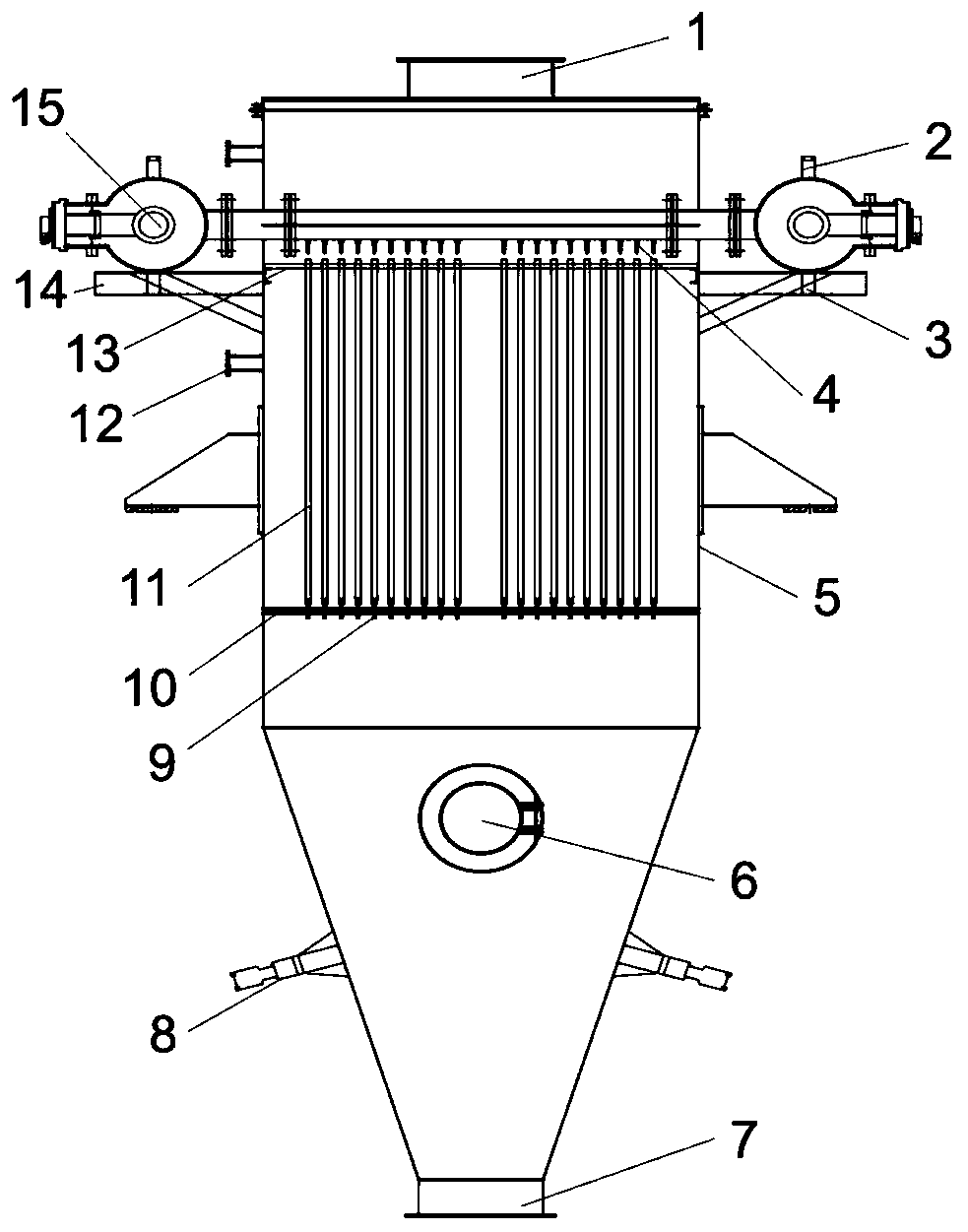

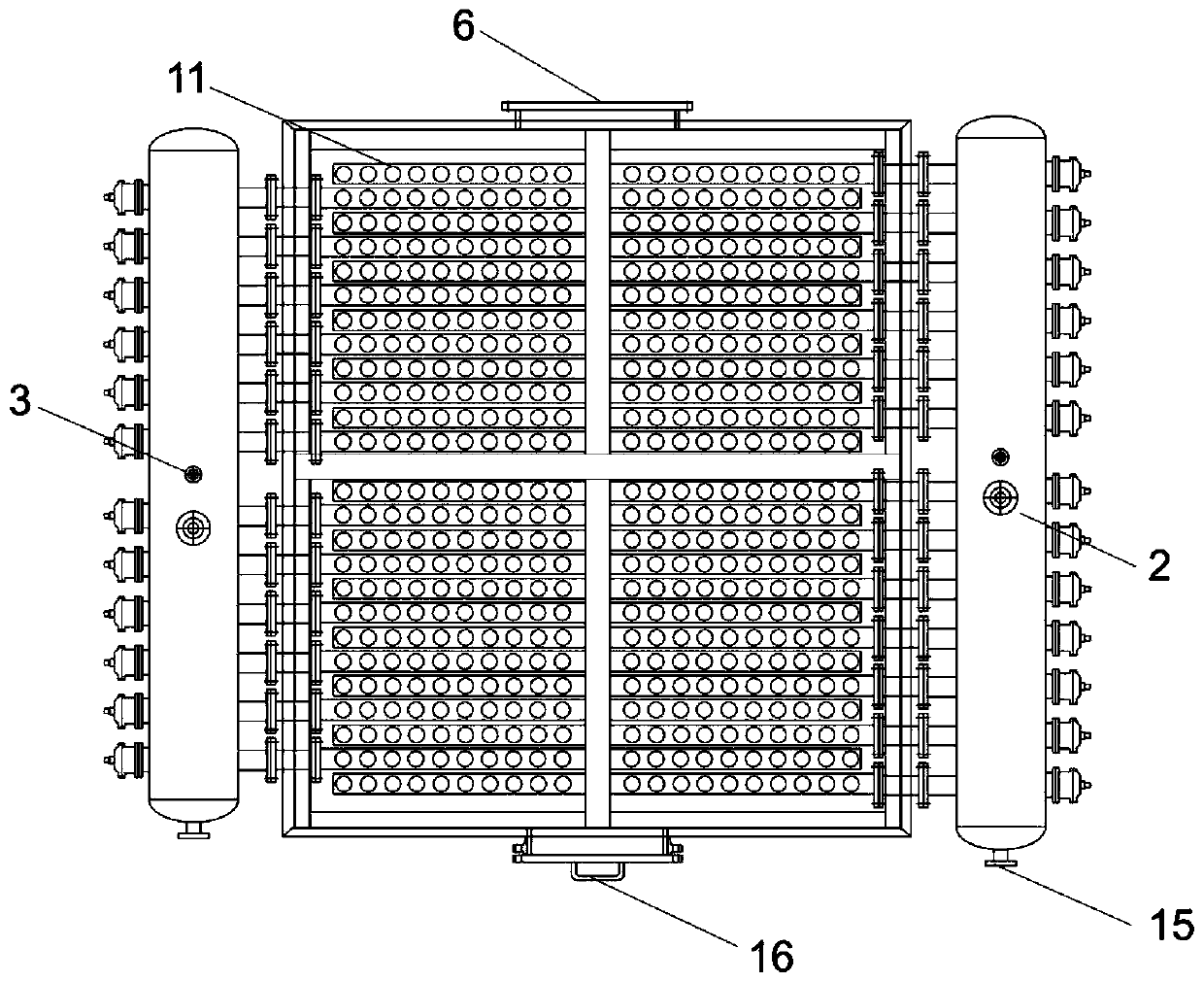

[0033]In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] The invention provides a method for preparing a silicon carbide asymmetric composite filter tube membrane with controllable aperture.

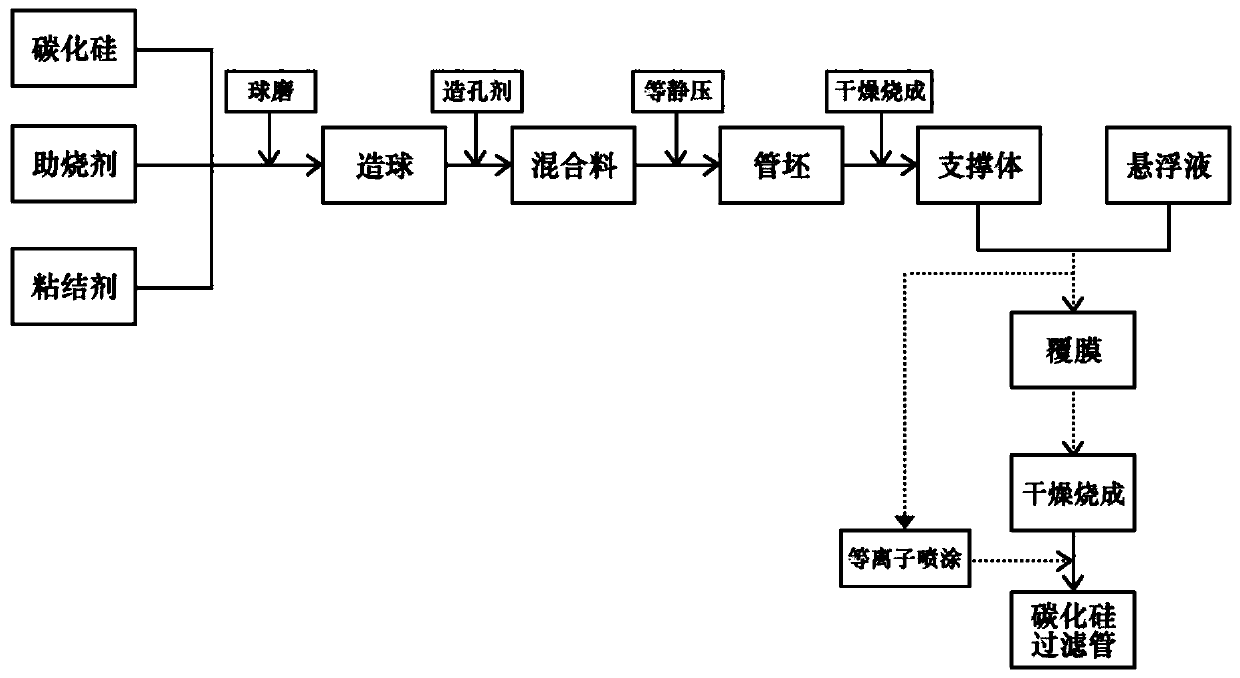

[0035] Such as figure 1 As shown, the method includes the following steps:

[0036] S1: Raw material crushing and grinding: respectively crush silicon carbide, pore-forming agent, sintering aid, and inorganic high-temperature binder to a particle size of less than 1mm; Grind for 5h-14h, pass through 220-380 mesh sieve respectively, and set aside;

[0037] S2: Mixing of raw materials: Add the raw materials prepared in S1 into a light ball mill for mixing according to the mass fraction ratio: 75%-90% of silicon carbide, 5%-15% of sintering aid, 5%-10% of inorganic high-temperature binder, and Distilled water is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com