Spinning flow high efficiency heat exchange pipe and its producing method

A manufacturing method and technology for heat exchange tubes, which are applied to the types of heat exchangers, indirect heat exchangers, tubular elements, etc., can solve the problems of easy formation of scaling on the inner wall of the heat exchange tubes, reducing the heat exchange efficiency of the device, and difficulty in smoothness, etc. To achieve the effect of reducing resistance, prolonging cleaning cycle, and enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing:

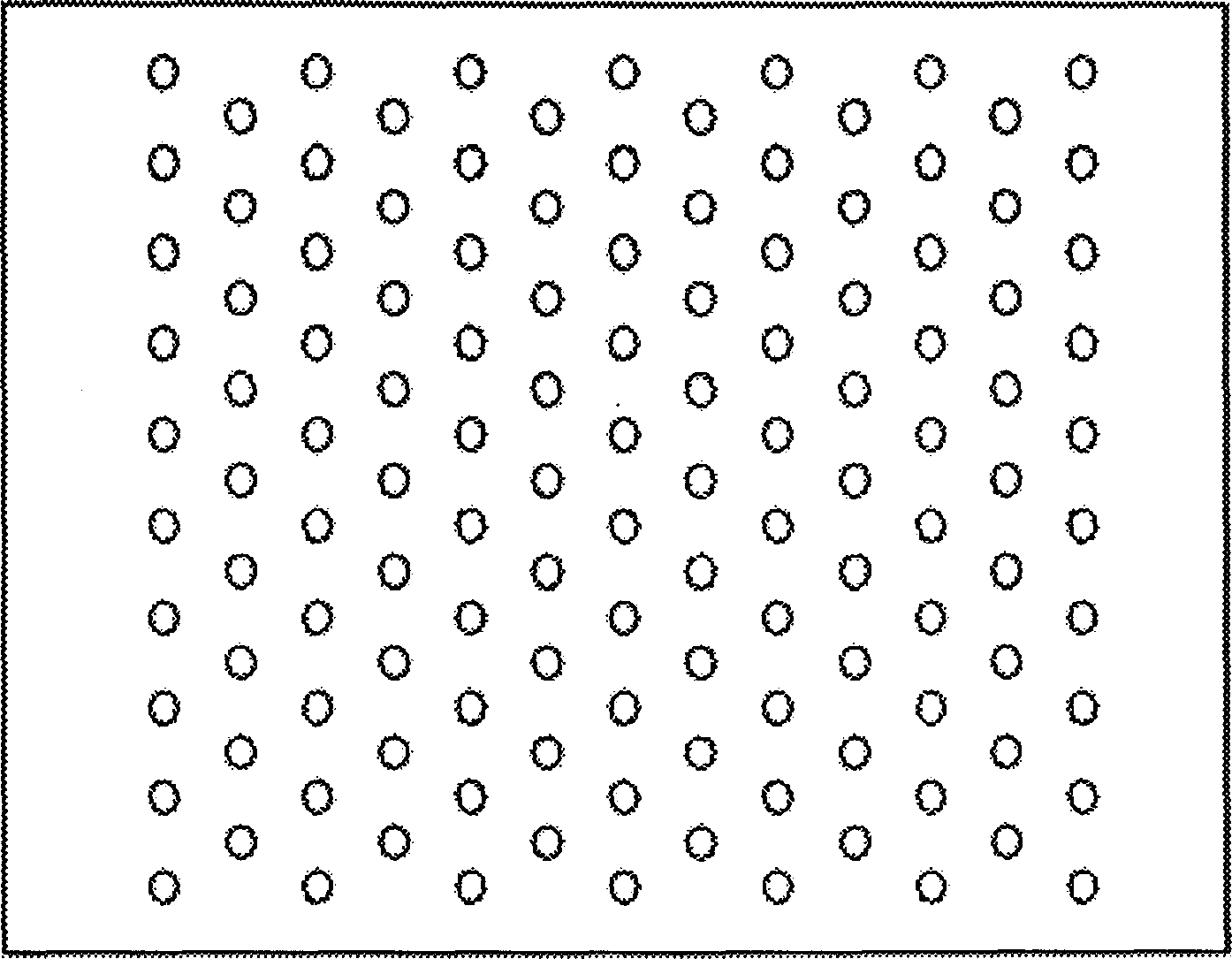

[0019] The heat exchange tube manufacturing method of the present invention is to mold the 2B-side thin steel plate according to the design requirement thickness specification with spherical protrusions on the surface. Sure. When the thin steel plate is molded, there should be no spherical protrusions within a certain length from the tube end to meet the welding or expansion requirements of the heat exchange tube and the tube sheet. Then cut the molded thin steel strips according to the expansion size of the heat exchange tubes of the required specifications to form the attached image 3 Slats shown.

[0020] Then the slats are stretched and compressed into pipes, and the pipe seams are welded, preferably by high-frequency welding, to form heat exchange pipes.

[0021] Then, the heat exchange tubes are combined with the tube sheets according to the process of the prior art to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com