White carbon black tail gas processing method and washing tower

A treatment method and technology of silica, applied in chlorine/hydrogen chloride purification, chlorine/hydrogen chloride and other directions, can solve the problems of easy clogging of washing towers, small particle size, high specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

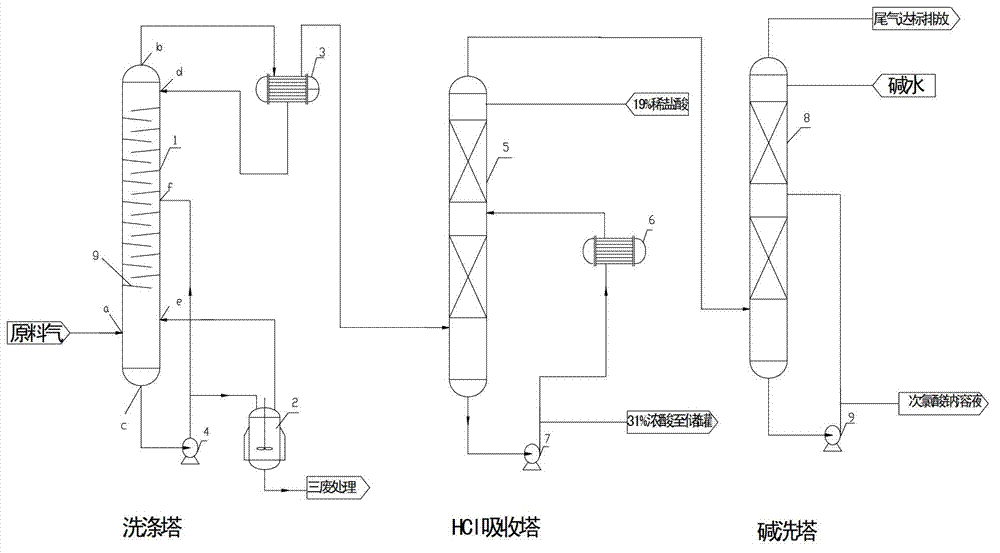

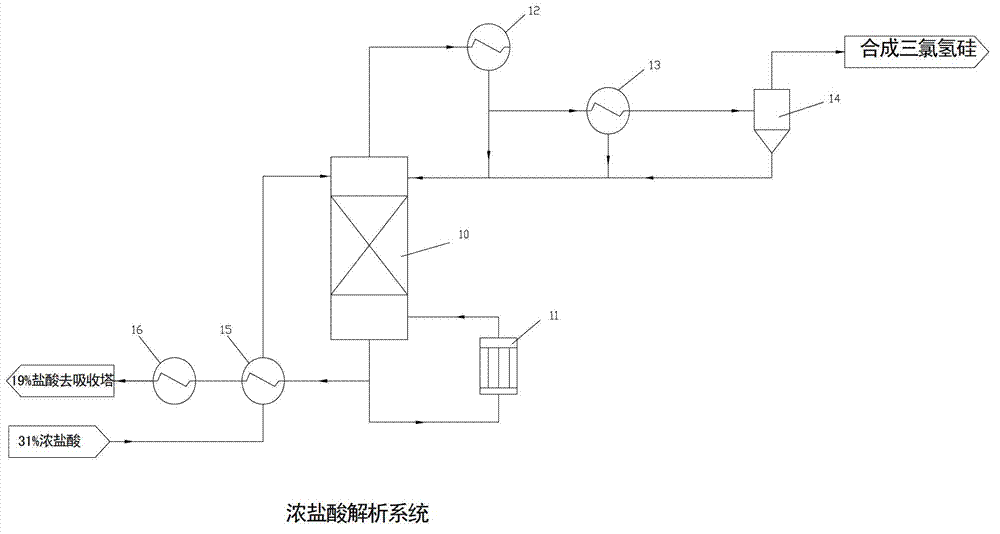

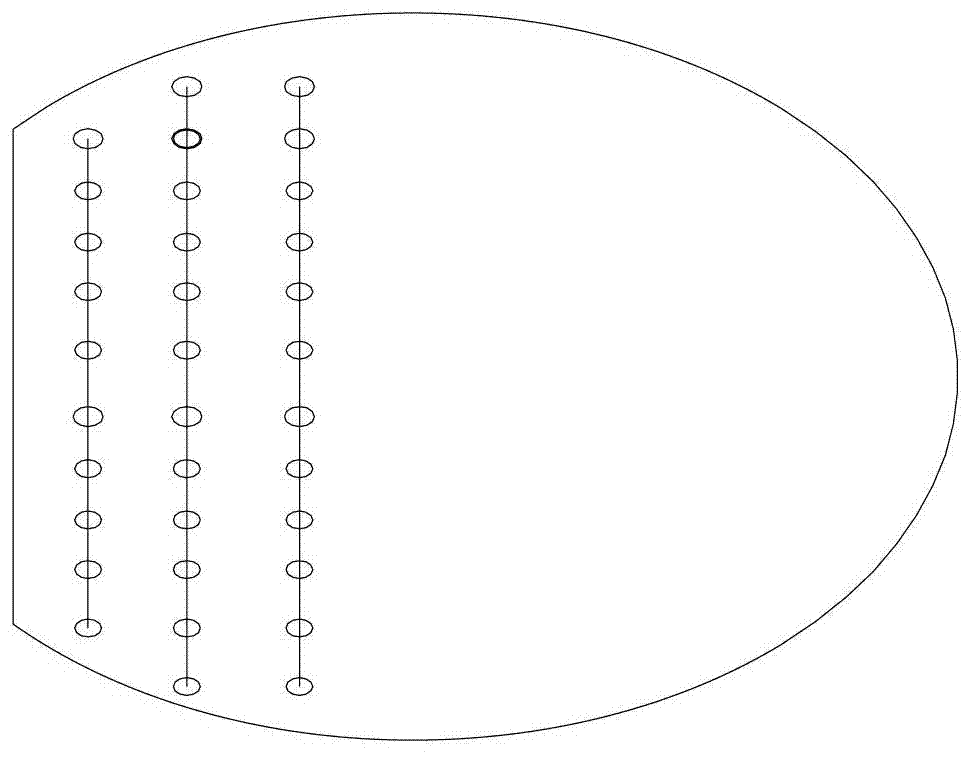

[0039] The tail gas produced during the synthesis of gas phase white carbon black is mainly composed of hydrogen chloride gas, air, a small amount of chlorine gas, and part of white carbon black dust. According to attached figure 1 The schematic diagram of the working process of the white carbon black tail gas treatment provided can clearly indicate the treatment process of the white carbon black tail gas, in which, figure 1 The 31% concentrated acid in the HCl absorption tower to the storage tank enters through the heat exchanger figure 2 The medium-concentrated hydrochloric acid analysis system performs concentrated acid analysis. image 3 It is a schematic diagram of the structure of the scrubber tray, which is represented by image 3 It can be clearly shown that the surface of the scrubber tray is provided with holes.

[0040] The specific process of white carbon black tail gas treatment is as follows: these gas-solid mixtures enter the scrubber from the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com