Quench cooler applied to entrained flow gasifier

A quencher and gasifier technology, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry to achieve the effects of convenient processing, large heat exchange capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

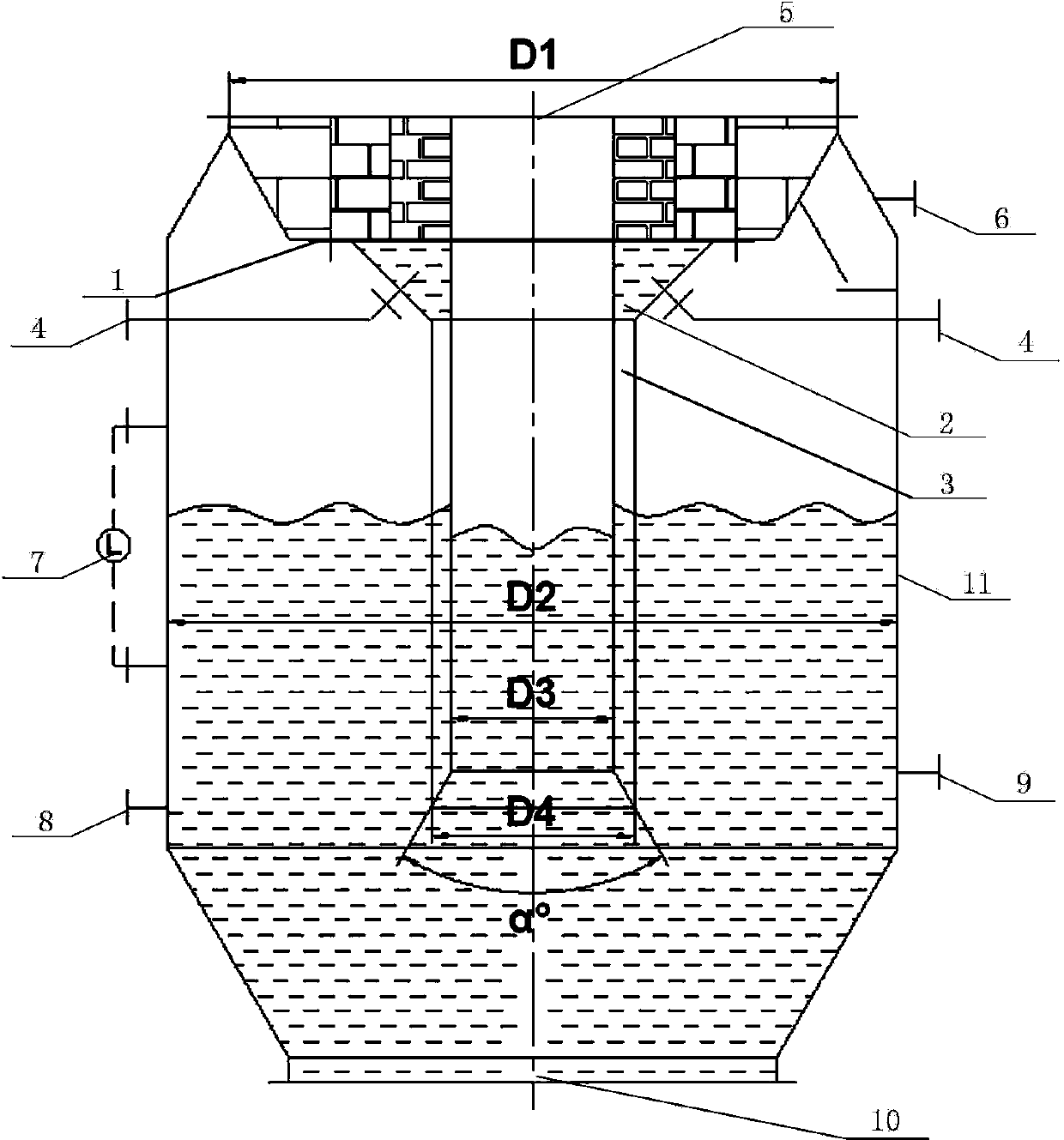

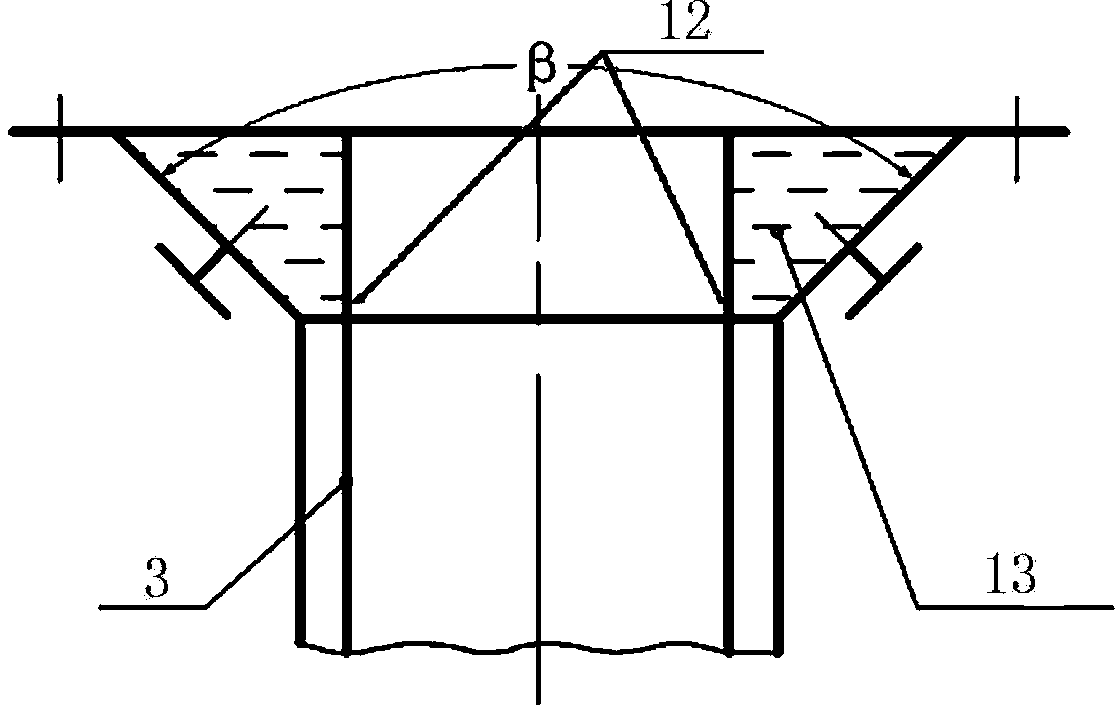

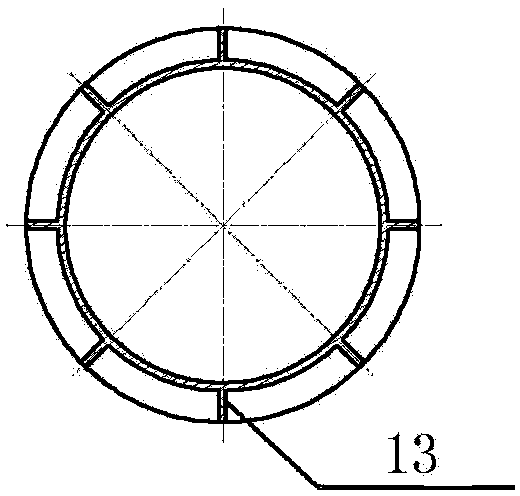

[0030] like figure 1 As shown, the quencher applied to the entrained gasifier is located at the lower end of the gasifier, and includes a shell 11, a quenching water distributor 2 and a gas deflector 3, and the quenching water distributor 2 and the gas deflector 3 are both provided With the inside of the housing 11, the gas baffle tube 3 is located in the middle of the housing 11; the shape of the housing 11 from top to bottom is the upper frustum-shaped head, the middle cylindrical part, and the lower rounded The table-shaped head, the upper circular table-shaped head is provided with a refractory brick support plate 1, the refractory brick support plate 1 is used to support the refractory bricks on the upper part of the quench cooler and the refractory bricks of the gasifier, and the refractory brick support plate 1 is connected to the emergency The cold water distributor 2; the quenching water distributor 2 is in the shape of a hollow inverted round table, the hollow part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com