Star-star type three-phase induction heat reactor

A technology of induction heating and reactors, applied in induction heating, induction heating devices, coil devices, etc., can solve problems such as sample metal contamination, and achieve high processing capacity, high-efficiency heating, and large liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

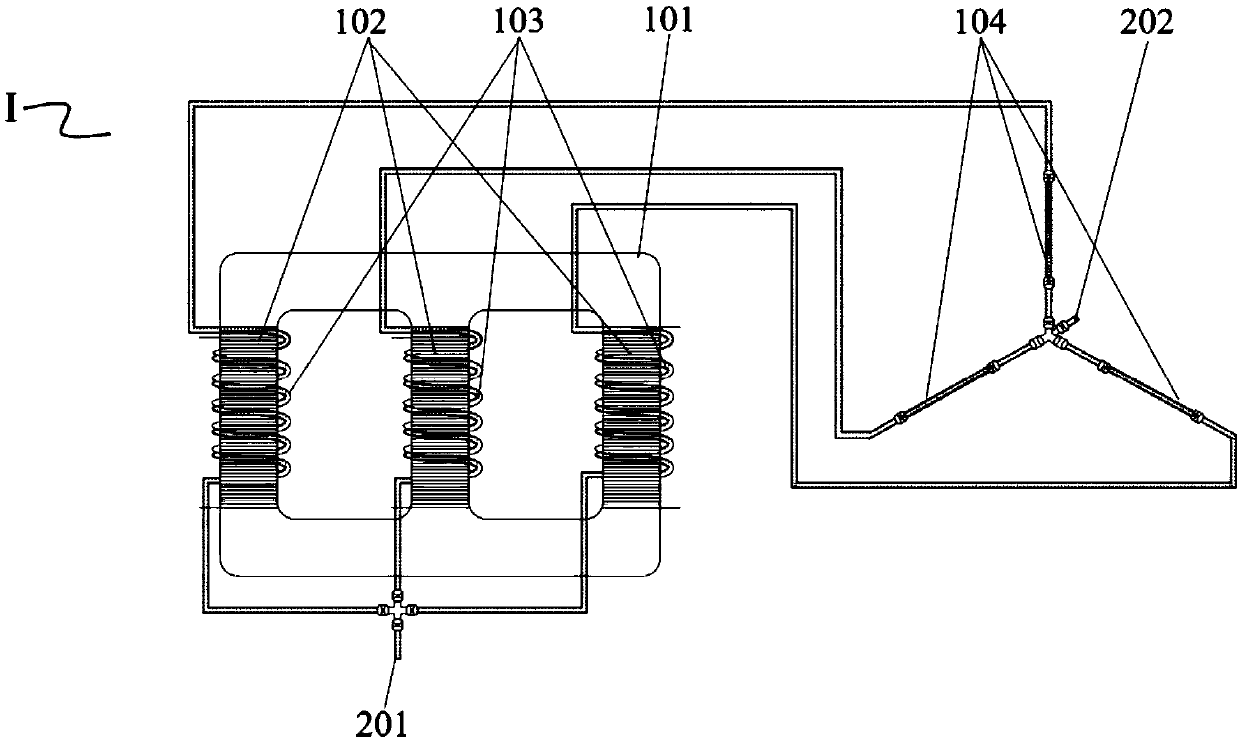

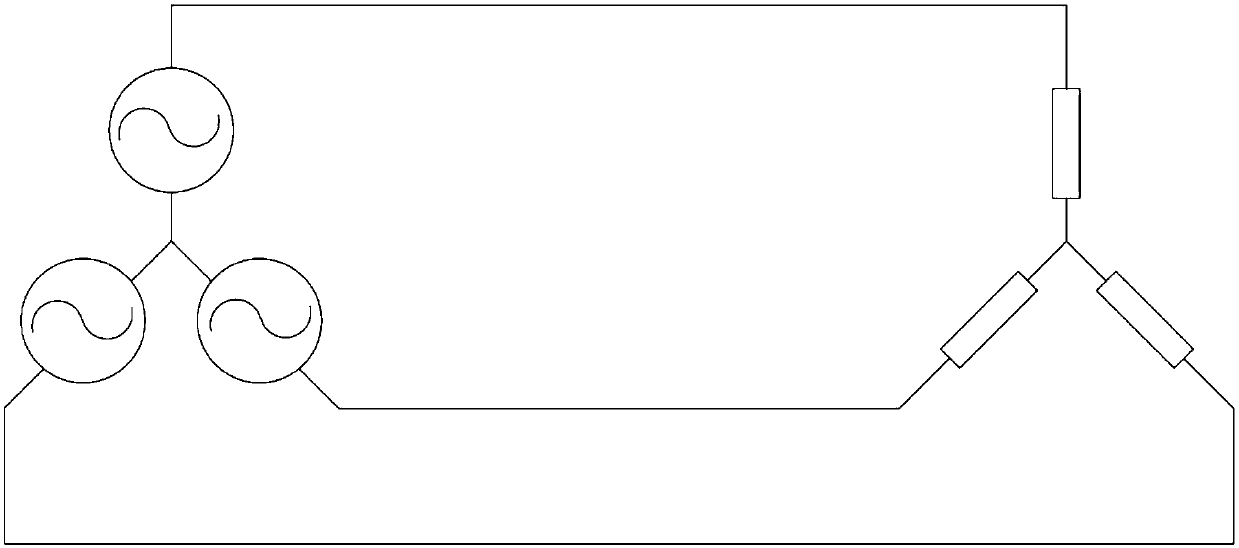

[0032] Star-star three-phase induction thermal reactor I, such as figure 1 As shown, it includes a three-column magnetic circuit 101, an excitation coil 102, a magnetic coupling tube group 103, and a reaction chamber group 104; wherein the magnetic coupling tube group 103 is star-connected; the reaction chamber group 104 is also star-connected; The port 201 and the sample outlet 202 are arranged at the connection intersection of the magnetic coupling tube group 103 or the reaction chamber group 104. In this embodiment, the sample inlet 201 is located at the connection intersection of the magnetic coupling tube group 103, and the sample outlet 202 is located at the reaction chamber group 104. The connection intersection of the chamber group 104 is taken as an example for illustration;

[0033] The excitation coil 102 is wound on each iron core column of the three-column magnetic circuit 101, and the number of turns of the excitation coil 102 on each iron core column is 6 turns,...

Embodiment 2

[0039] Star-star three-phase induction thermal reactor I, such as figure 1As shown, it includes a three-column magnetic circuit 101, an excitation coil 102, a magnetic coupling tube group 103, and a reaction chamber group 104; wherein the magnetic coupling tube group 103 is connected in a star shape; the reaction chamber group 104 is also connected in a star shape.

[0040] The excitation coil 102 is wound on each iron core column of the three-column magnetic circuit 101, and the number of turns of the excitation coil 102 on each iron core column is 12 turns, and a three-phase power supply is used to apply an average voltage of 2000V to the excitation coil 102, Then the magnetic flux of each iron core column in the three-column magnetic circuit 101 is 0.12Wb. At this time, the magnetically conductive material of the three-column magnetic circuit 101 is cobalt-based amorphous, and the initial relative magnetic permeability is 35000. The magnetic flux density during operation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com