Gas-liquid contacting response operator of fluid curtain bed

A gas-liquid contact and reaction device technology, which is applied in the chemical method of reacting liquid and gas medium, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of small load adjustment range, large system resistance and low mass transfer coefficient. and other problems, to achieve the effect of less internal components, good load regulation performance, and large gas-liquid contact surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

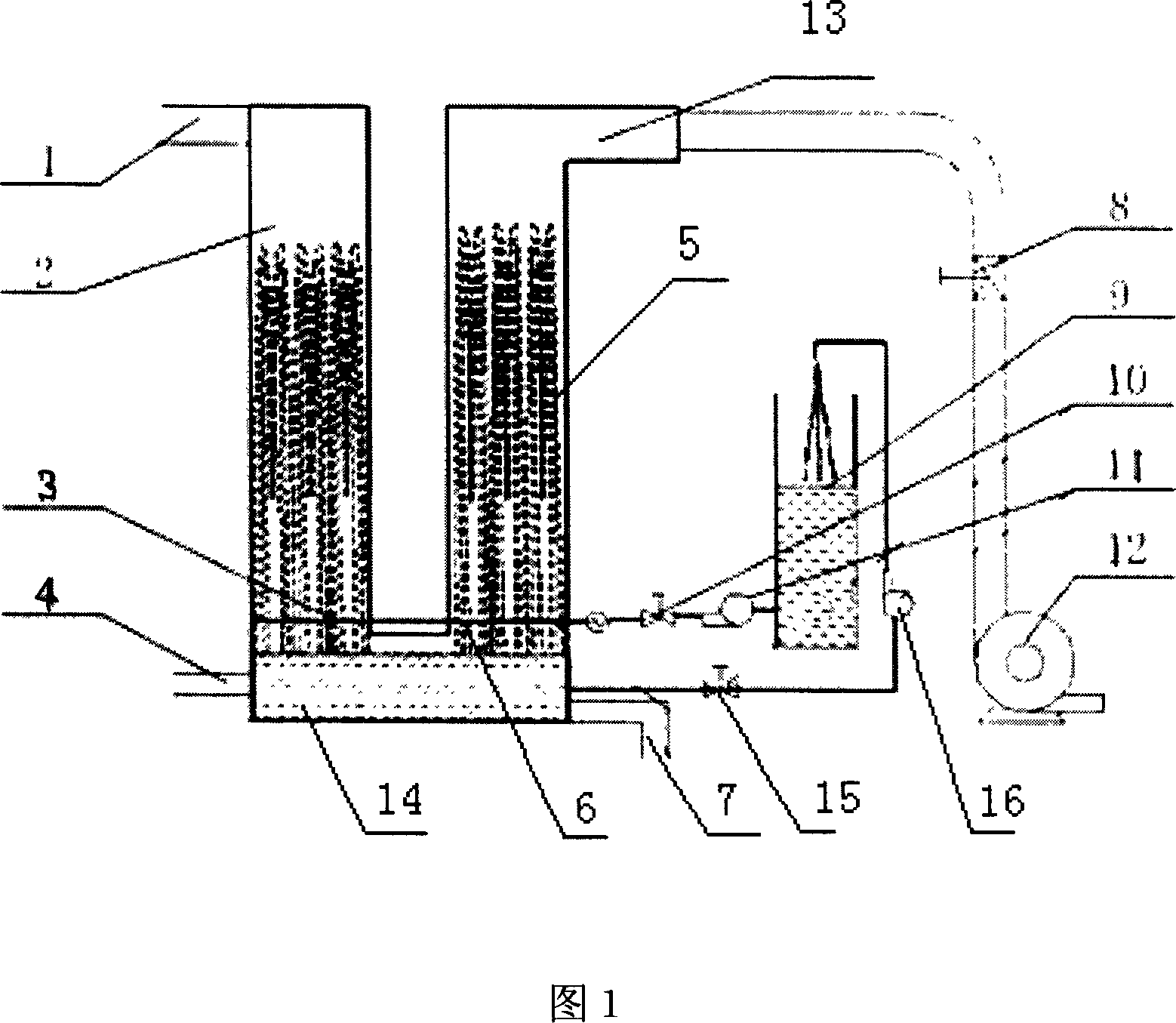

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

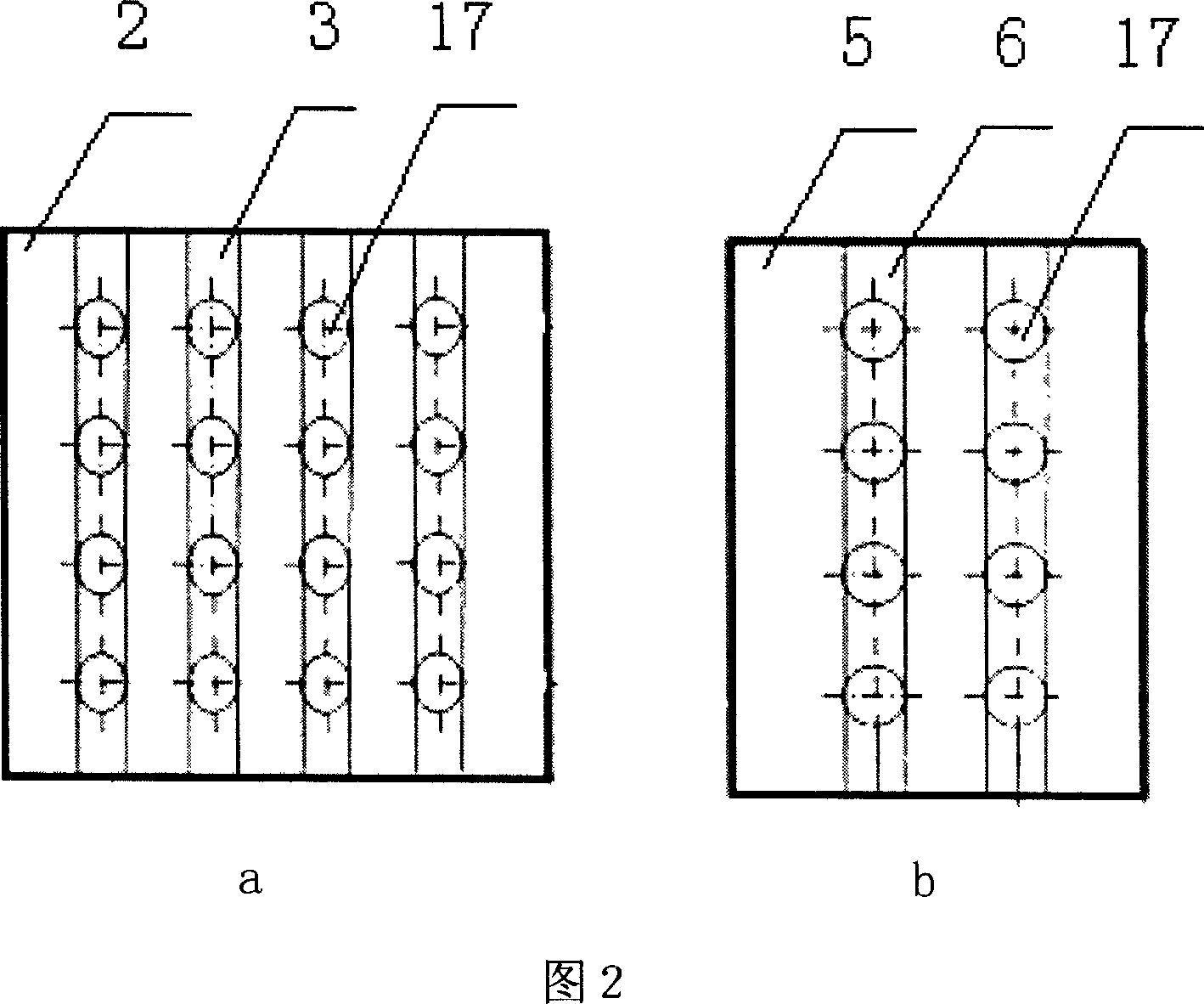

[0010] Referring to Fig. 1, the present invention comprises a slurry pool 14 with a slurry inlet 4 and a slurry outlet 7 and a downstream tower 2 and a countercurrent tower 5 with a flue gas inlet 1 and a flue gas outlet 13 at the upper end, the downstream tower 2 and the countercurrent The tower 5 is arranged in parallel on the pulp tank 14 and the downstream tower 2 is connected with the bottom of the countercurrent tower 5, and the flue gas outlet of the countercurrent tower 5 is connected with the induced draft fan 12 through the draft valve 8, and the downstream tower 2 and the countercurrent tower 5 are connected to each other. The bottom of the tower 5 is respectively provided with more than one row of connected downstream tower nozzles 3 and countercurrent tower nozzles 6. The nozzles communicate with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com