Boiling bed residual oil hydrocracking process

A technology of hydrocracking and bed residue, which is applied in the fields of hydrocarbon oil cracking and petroleum industry, etc., which can solve the problems of not being able to give full play to the high dispersion and high activity of the catalyst, and achieve the effects of improving utilization rate, improving product quality and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

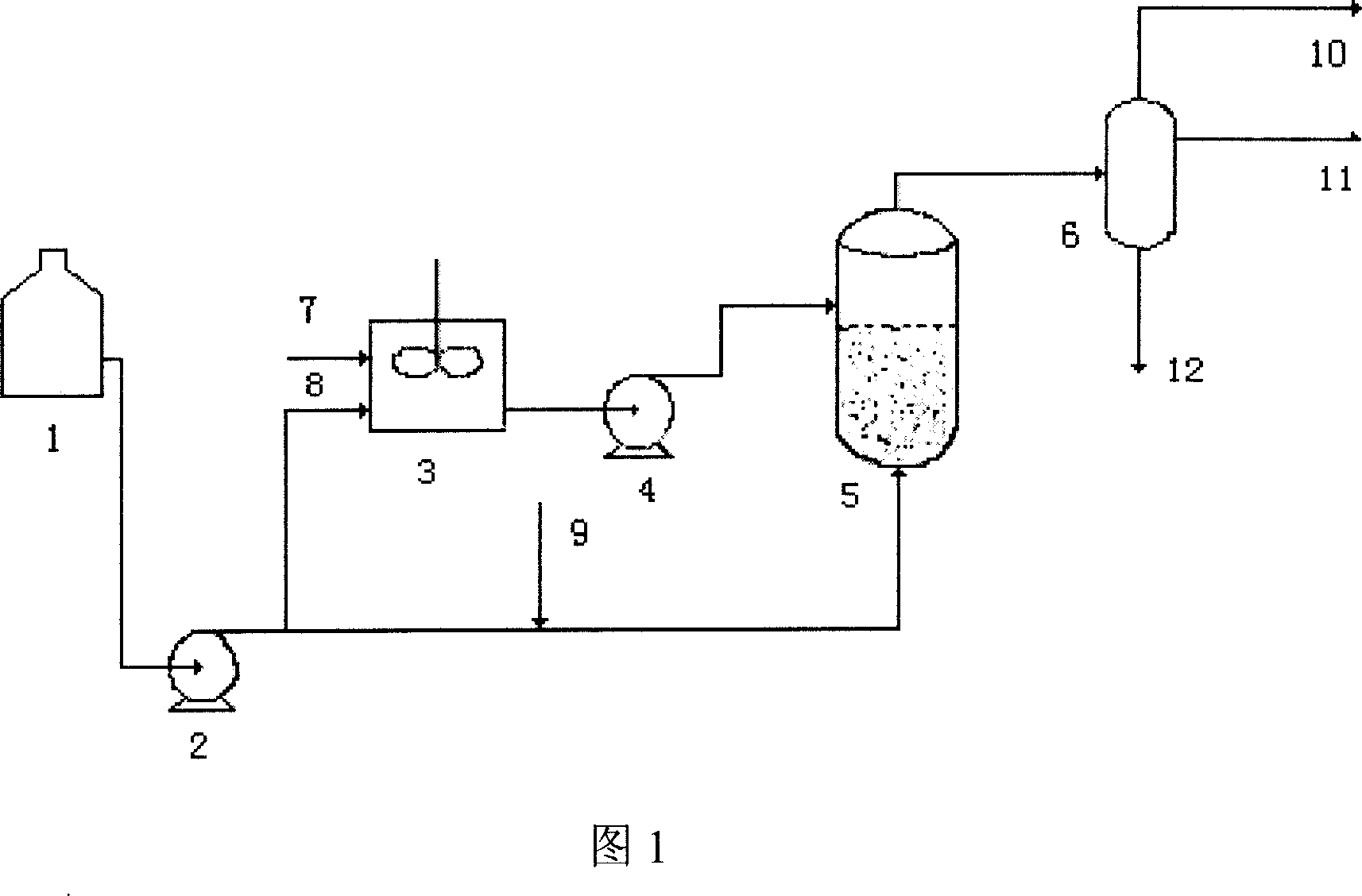

[0023] As shown in Figure 1, the process flow of the fluidized bed residual oil hydrogenation using supported and dispersed catalysts is as follows: all or part of the heavy and residual oil raw materials in the raw material tank 1 are pressurized by the pump and then mixed with high-pressure hydrogen 9 for further processing. The way of feed enters the ebullating bed reactor that load-type catalyst is housed from the bottom of ebullating bed reactor 5 to keep the catalyst boiling, and part of the raw material or other hydrocarbons and catalyst aqueous solution from the raw material tank 1 and the raw material pump 2 are mixed in the mixer 3 Mix well and evenly in the medium, and enter the liquid phase area without catalyst or the sedimentation area of the loaded catalyst through the dispersed catalyst delivery pump 4 of the ebullated bed reactor. The supported catalyst is in contact with the dispersed water-soluble catalyst to carry out catalytic hydrogenation reaction, and ...

Embodiment 1-2

[0029] This example is an ebullating bed hydrogenation test using a supported catalyst and a dispersed catalyst. The specific operation process is shown in Figure 1. The residual oil raw material in the raw material tank 1 is pressurized by a pump and then mixed with high-pressure hydrogen 9. The above feed enters the ebullating bed reactor equipped with a supported catalyst from the bottom of the reactor 5 to keep the catalyst boiling. From the raw material tank 1 and Part of the raw materials of the raw material pump 2 and the catalyst aqueous solution are fully mixed in the multi-stage shear tank 3, and then enter the catalyst-free liquid phase area of the ebullated bed reactor through the dispersed catalyst delivery pump 4. Under the specified reaction conditions, from the reactor The heavy residue raw material entering from the bottom contacts with the supported catalyst and the dispersed water-soluble catalyst successively to carry out catalytic hydrogenation reaction,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com