Smoke gas desulfurization dust removal device by turbulent ball type turbocharging acceleration

A turbocharging, desulfurization and dust removal technology, applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of complex cyclone structure, reduced desulfurization efficiency, easy scaling, etc., and achieve continuous work The effect of long time, small liquid-gas ratio and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

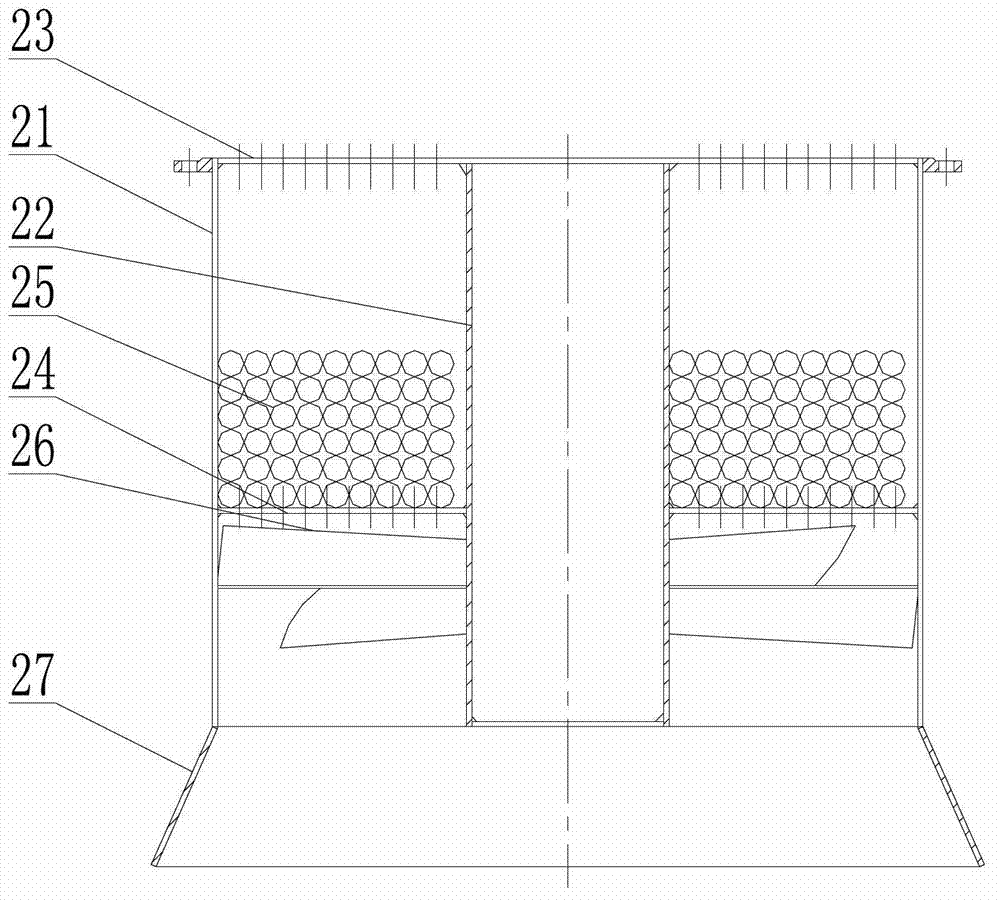

[0021] The structural drawings and embodiments of a turbulent ball turbocharged desulfurization and dust removal device proposed by the present invention are described in detail as follows:

[0022] The overall structure of an embodiment of the present invention is as follows figure 2 Including: a shell 21, a pipe 22 fixed in the center of the shell, upper and lower porous end plates 23, 24 respectively arranged on the upper end and the middle of the shell; filling in the space between the upper and lower porous end plates 23, 24 of the shell A turbulent ball 25; a plurality of blades 26 installed between the porous partition 24 and the pipeline, the upper end of each blade is connected with the inner wall of the housing, and the lower end is connected with the outer wall of the pipeline; the lower end of the housing is connected with a smoke shield Cover 27.

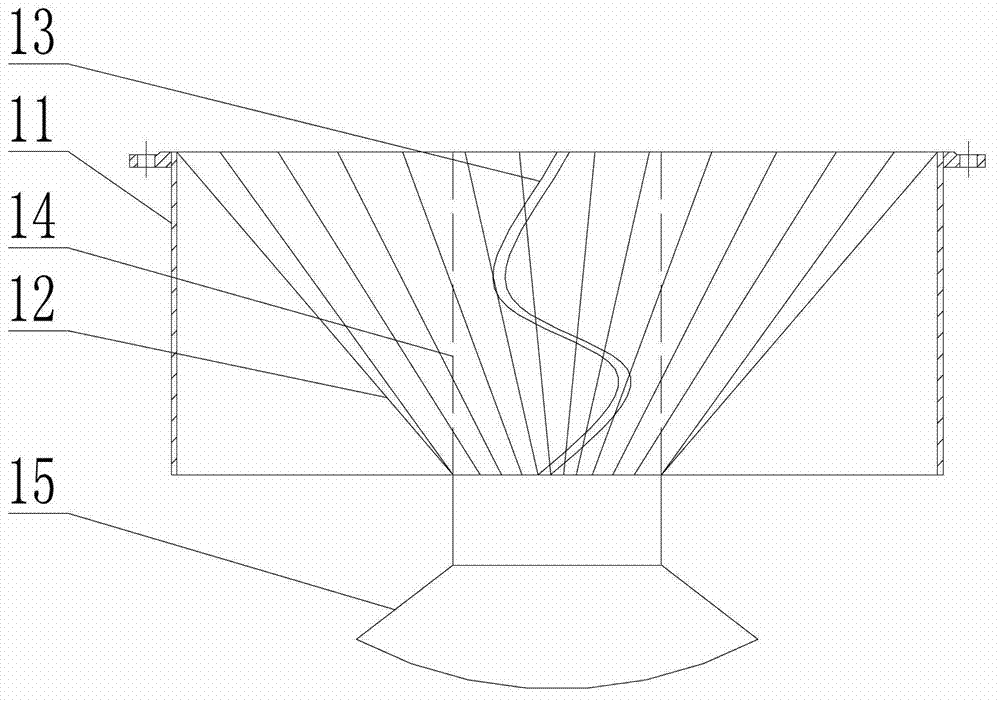

[0023] The structure of the turbulent ball type turbocharged accelerated flue gas desulfurization and dust removal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com