Wet type static solid strip-shaped anode dust collecting plate

A technology of wet electrostatic and dust collection plate, applied in the field of anode plate of wet electrostatic dust removal/defogging, can solve the problems of sticking plate fouling, low liquid holding capacity and low liquid holding capacity, etc., to prevent static precipitation. Tendency, prevent fouling and fouling, and increase the effect of liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The pole plate structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] The present invention can be realized by two kinds of structures:

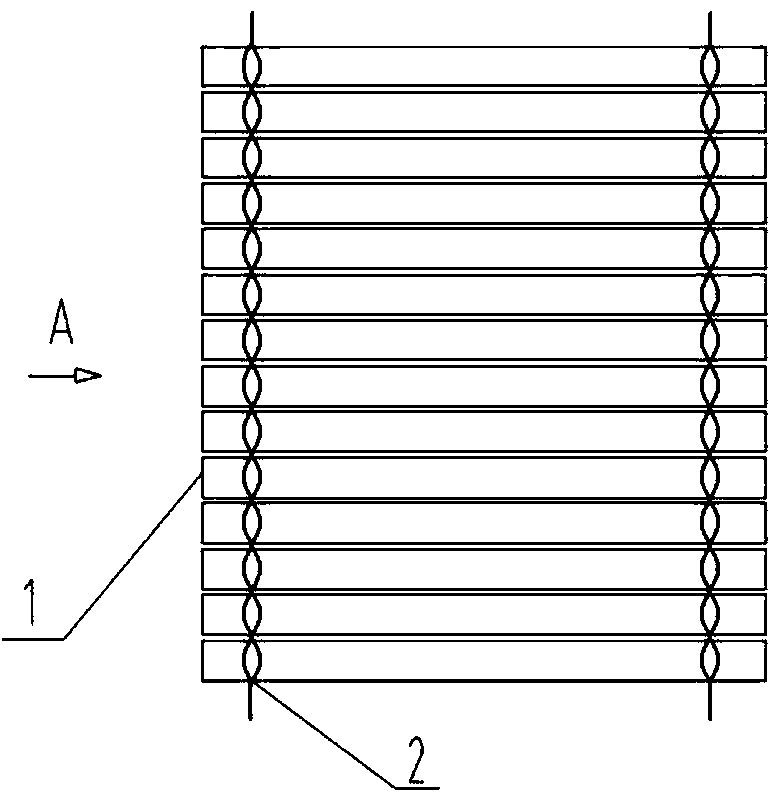

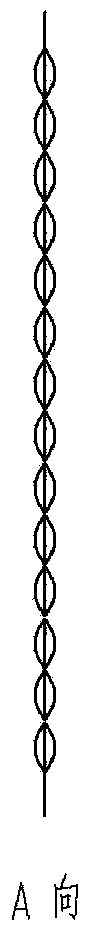

[0011] 1) Rope braided plates: figure 1 The middle strip 1 is a rectangular strip: height b=10-100mm, transverse length l=400-1600mm, thickness σ=2-10mm. The strips are braided together by braiding rope 2 to form a solid plate with local rigidity and overall flexibility. The diameter and braiding method of the braided rope adjust the transverse gap. The pole plate is hung on the upper support frame by the braided rope, and the spray water pipe is arranged on the upper part to form a wet flexible solid dust collection anode.

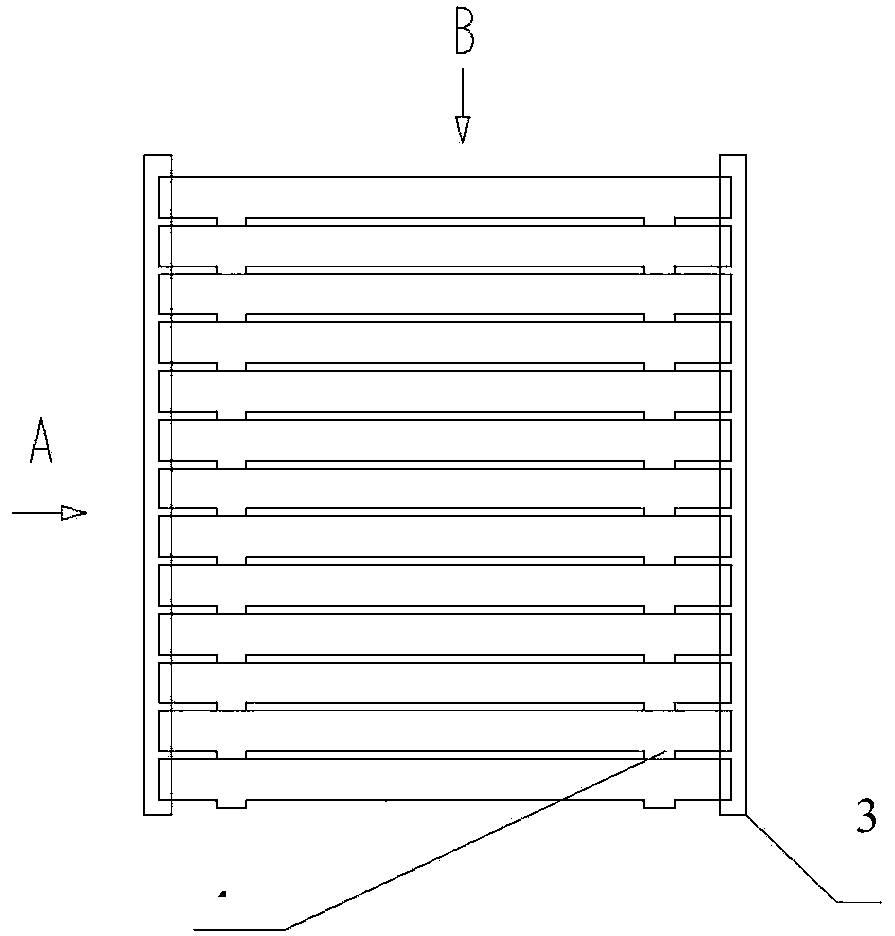

[0012] 2) Pole plates assembled with vertical splints: image 3 The middle strip 4 is a rectangular strip: height b=10-100mm, transverse length l=400-1600mm, thickness σ=2-10mm. Put the strip 4 into the vertical splint 3 to form a wet solid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com