Rectifying tower for separating and purifying ethyl hexanoate

A technology of ethyl hexanoate and rectification tower, applied in the field of chemical tower equipment, can solve the problems of small production capacity, low plate efficiency, small operation flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

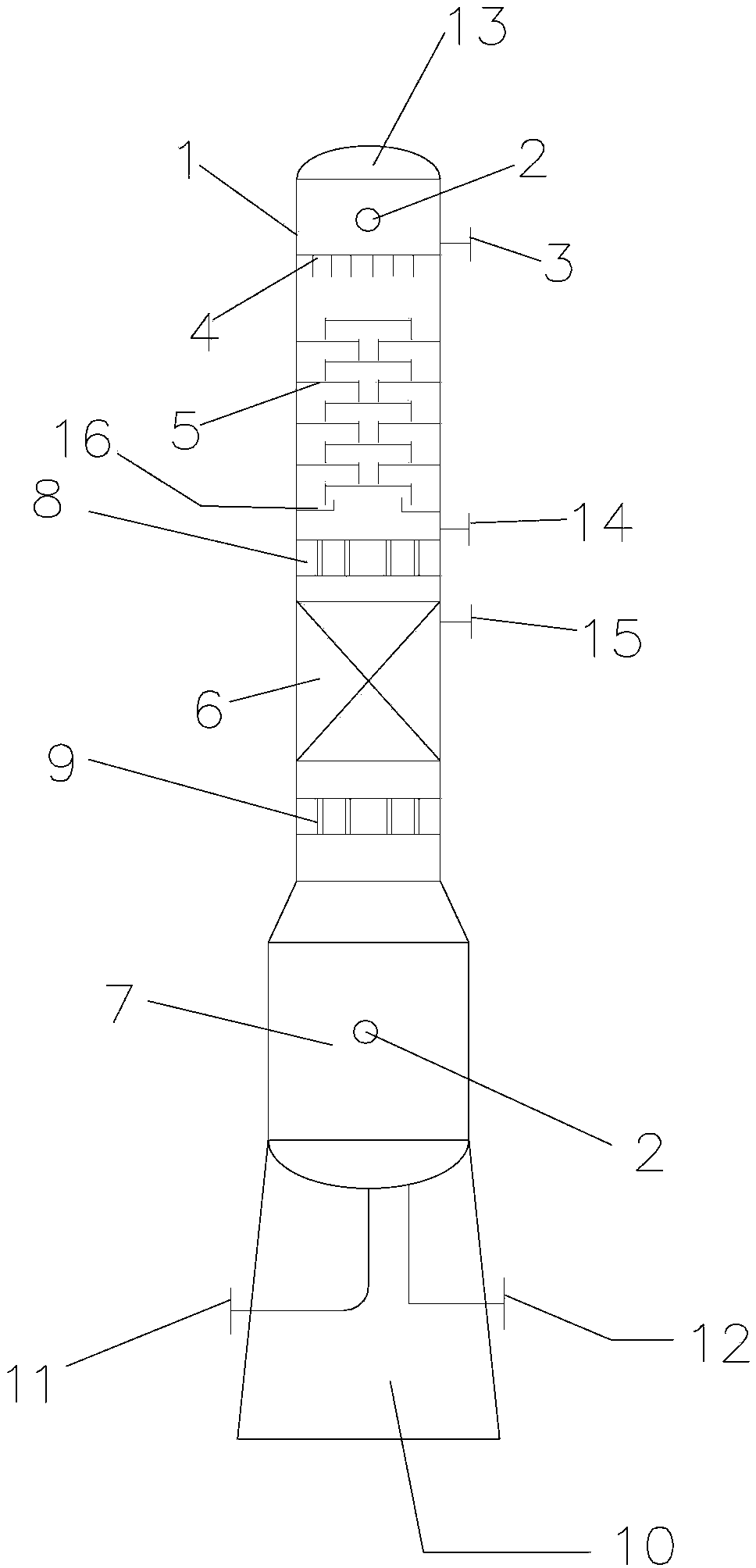

[0015] Such as figure 1 As shown, a rectification tower for separating and purifying ethyl hexanoate comprises a cylinder 1 of the rectification tower, internal parts, a head 13, a bracket 7 and a skirt 10, and the rectification section of the rectification tower adopts The double overflow trays are arranged, the stripping section adopts packing, and the bottom of the rectifying section and the stripping section is provided with a first cyclone separator 8 and a second cyclone separator 9, and a liquid distributor is provided above the tray below the reflux port. 4, a liquid seal plate 16 is arranged between the tray at the bottom of the rectification section and the first cyclone separator 8, and a side line extraction port 15 is arranged on the barrel of the stripping section. Two manholes 2 are also arranged on the cylinder body. The rectification column has 9 trays and a section of packing. The packing is metal corrugated structured packing. The reflux port 3 is located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com