System and method for producing n-butyl acetate by using methyl acetate and n-butyl alcohol ester exchange reaction

A technology of n-butyl acetate and transesterification reaction, which is applied in the system field of preparing n-butyl acetate, can solve the problems of product refinement and raw material recovery, catalyst and product can not be separated, n-butyl acetate is difficult, etc., to avoid special Requirements, easy operation, and the effect of eliminating "three wastes" pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

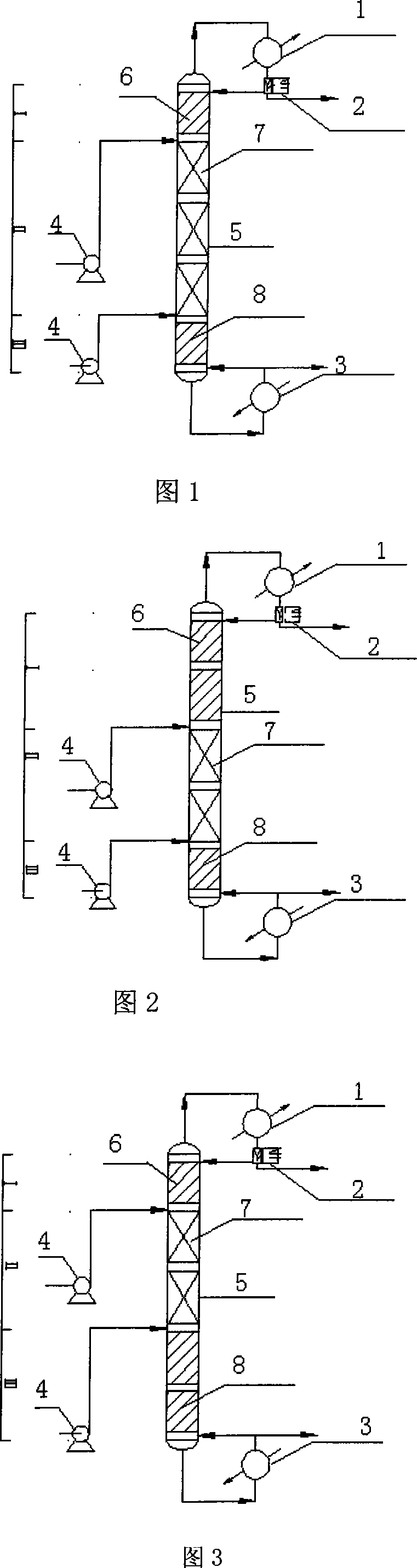

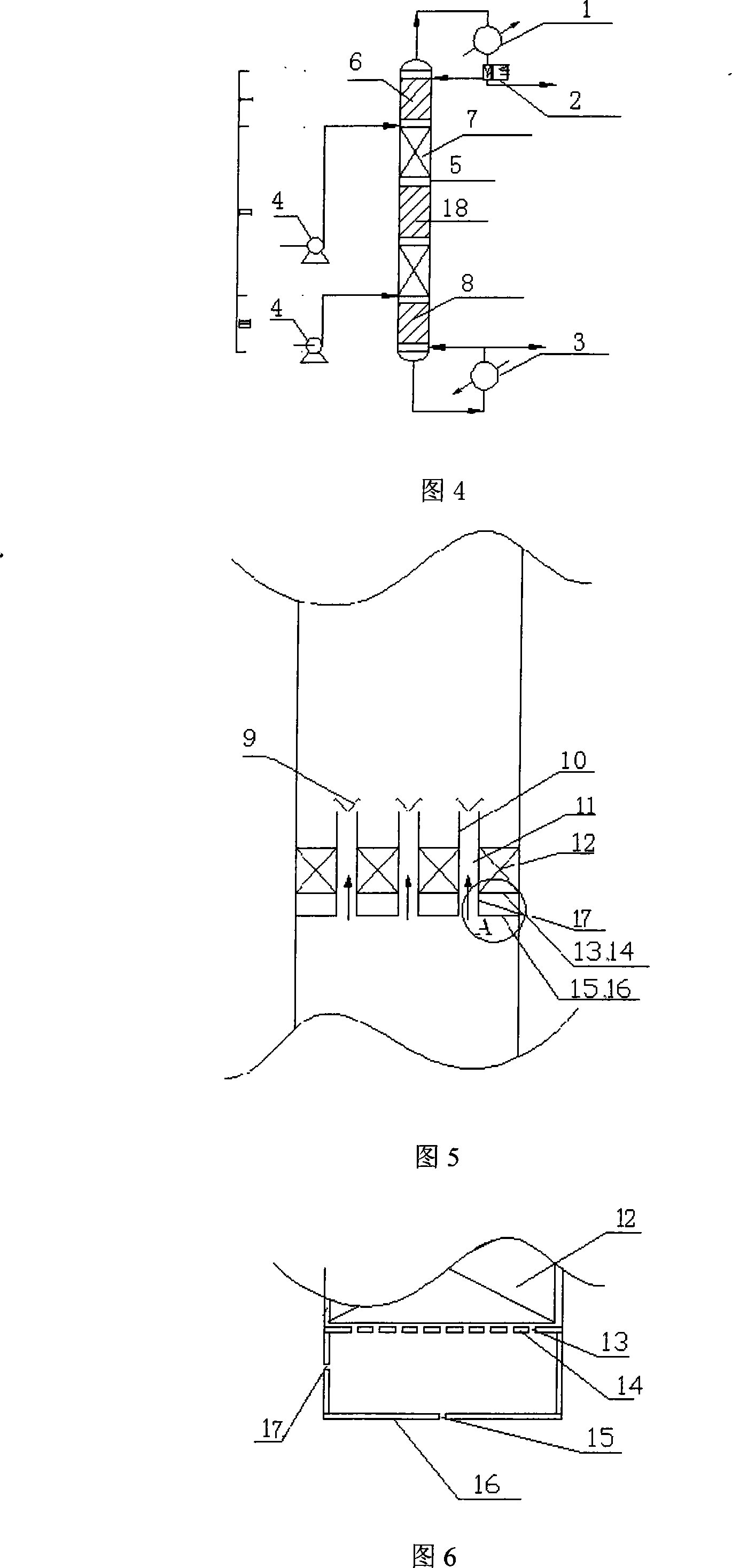

[0025] As shown in Fig. 1, Fig. 5 and Fig. 6, a kind of system of the present invention utilizes the transesterification reaction of methyl acetate and n-butanol to prepare n-butyl acetate, comprises condenser 1, reflux ratio controller 2, reboiler 3. Feed pump 4 and catalytic rectification tower 5. The catalytic rectification tower is composed of rectification zone I, catalytic reaction zone II and stripping zone III. The reboiler is connected with the bottom of the stripping zone in the catalytic rectification tower to provide heat for the catalytic rectification tower. The condenser is connected with the top of the rectification zone in the catalytic rectification tower to provide reflux liquid for the catalytic rectification tower. The reflux ratio controller is connected with the condenser and the top of the rectification zone in the catalytic rectification tower, and is used for controlling the reflux ratio of the catalytic rectification reaction. The catalytic reactio...

Embodiment 1

[0037] A glass catalytic rectification tower with an inner diameter (diameter) of 80mm is used, in which the catalytic reaction section is 1000mm high, the rectifying section is 500mm high, and the stripping section is 800mm high. The catalyst in the catalytic reaction section is cation exchange resin D001 type. The packing in the stripping section is CDG-1700y, the packing in the stripping section is θ ring packing, 12 sieve holes with a size of 3mm (circular, triangular distribution), and 8 tear holes with a size of 0.2mm (triangular, strip-shaped distribution), The total cross-sectional area of 10 overflow holes with a size of 2 mm (distributed in a circle and a triangle), 7 leak holes with a size of 0.5 mm (distributed in a circle and a rectangle), and a riser with a circular cross-section accounts for 25% of the cross-section of the catalytic rectification tower, the height is 800mm.

[0038] Methyl acetate and n-butanol are respectively added in the catalytic rectifica...

Embodiment 2

[0040] A glass catalytic rectification tower with a tower inner diameter (diameter) of 80 mm is used, wherein the catalytic reaction section is 3000 mm high, the rectifying section is 500 mm high, and the stripping section is 800 mm high. The catalyst in the catalytic reaction section is cation exchange resin NKC-9 type. The packing in the distillation section is triangular spiral packing, the packing in the stripping section is BX-500 type, 7 sieve holes (triangular, strip distribution) with a size of 10mm, and 5 tear holes (circular, triangular) with a size of 0.2mm distribution), 15 overflow holes with a size of 0.5mm (rectangular, rectangular distribution), 12 leakage holes with a size of 0.5mm (triangular, strip-shaped distribution), and 2 risers with a circular cross section

[0041] The sum of the cross-sectional areas (triangular distribution) accounts for 30% of the cross-section of the catalytic rectification tower, and the height is 2400mm.

[0042] Methyl acetate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com