Regular catalytic packing in catalytic distillation column and preparation method of regular catalytic packing

A technology of catalytic rectification tower and catalytic packing, which is applied in the field of structured catalytic packing and its preparation, mass transfer and separation process optimization and strengthening in catalytic rectification tower, which can solve the problem of unfavorable catalyst and reactant transfer and catalyst utilization efficiency Low, small contact area and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

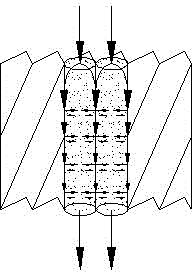

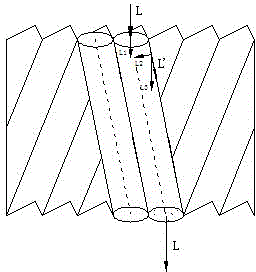

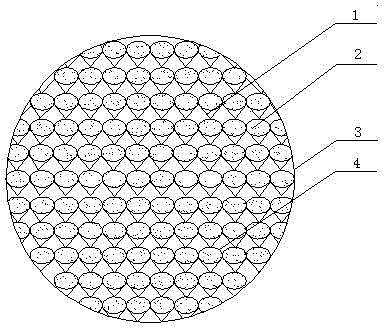

[0023] Select a catalytic rectification tower with an inner diameter of 300 mm, and the diameter of the catalytic packing is 300 mm, see the attached image 3 , the catalytic packing is composed of multiple pieces of catalyst bundles (component I) and regular corrugated packing (component II) arranged alternately, wherein the catalyst bundle (component I) is made as follows: first fold a piece of 300 mm×220 mm nylon cloth in half Make a large cloth bag of 300 mm×110 mm, draw a group of parallel lines with a horizontal inclination angle of 60° on the large cloth bag with a right-angled triangle with a 60° angle, and the horizontal interval between the two parallel lines is 10 mm, and use a sewing machine Sew along the line to form a group of small catalyst cloth bags, which are filled with cation exchange resin NKC-9, accounting for 90% of the total volume of the small catalyst cloth bags, and sealed with a sewing machine to form a catalyst bundle (component I); using the same m...

Embodiment 2

[0027] Select a catalytic rectification tower with an inner diameter of 300 mm, and the diameter of the catalytic packing is 300 mm, see the attached image 3 , the catalytic packing is composed of multiple pieces of catalyst bundles (component I) and regular corrugated packing (component II) arranged alternately, wherein the catalyst bundle (component I) is made as follows: first, a 300 mm × 220 mm silk cloth Fold it in half into a large cloth bag of 300 mm×110 mm, draw a group of parallel lines with a horizontal inclination angle of 60° on the large cloth bag with a right-angled triangular plate containing 60°, and the horizontal interval between the two parallel lines is 10 mm, use The sewing machine is stitched along the line to form a group of small catalyst cloth bags, which are filled with solid super acid, accounting for 70% of the total volume of the small catalyst cloth bags, and sealed with a sewing machine to form a catalyst bundle (component I); using the same meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com